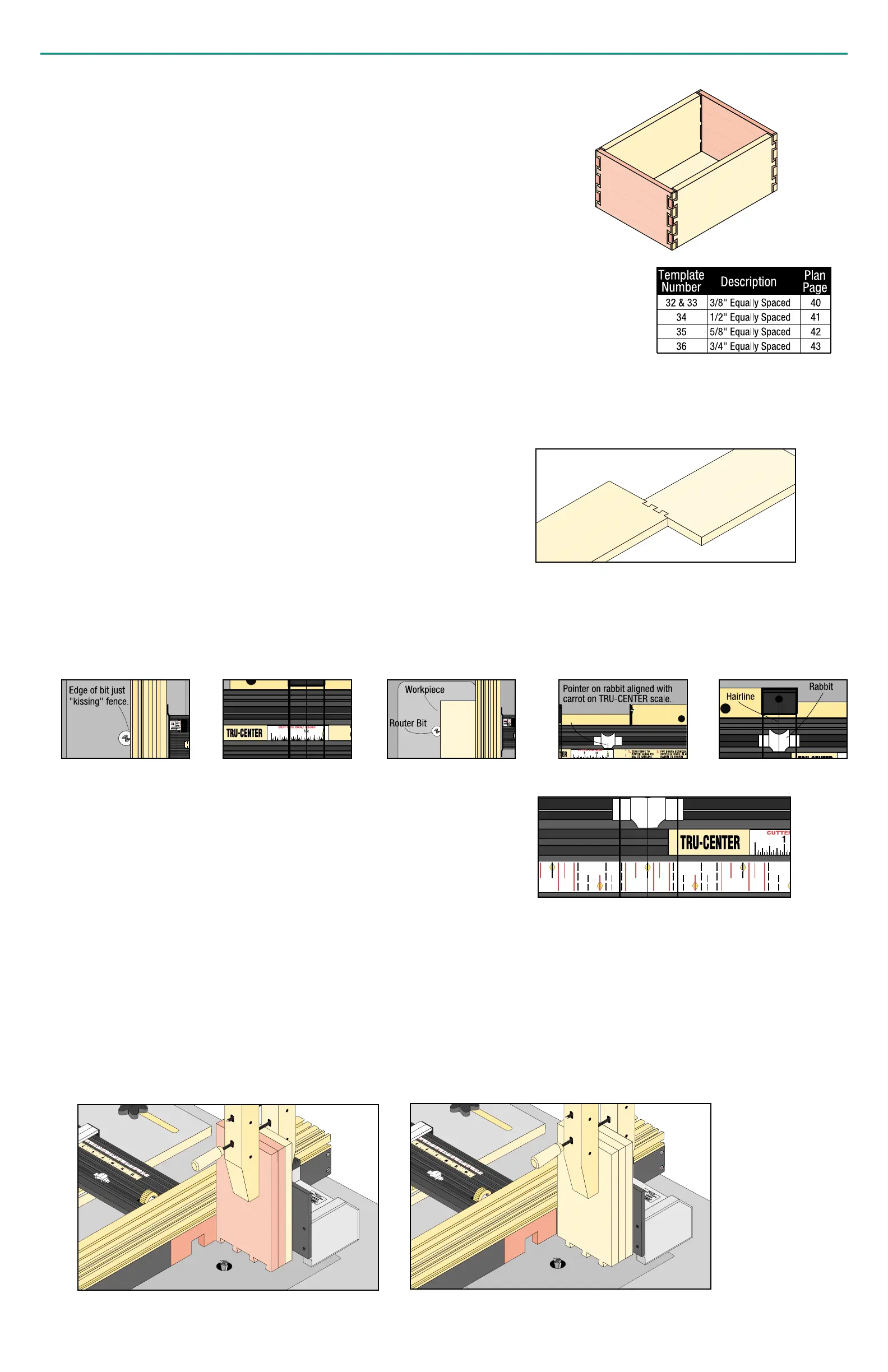

JOINT MAKING OPERATIONS

The Boxtail Joint is one of the more exotic appearing joints. Rather than dovetails only on

one side as with the Half Blind or Through Dovetail, the Boxtail has dovetails appearing

on both sides of its joint.

To make this joint the material thickness must be the same as the depth of cut. You must

either plane the stock to the depth of cut as determined by the fit of the joint or rabbet the

stock in the joint area to get the proper thickness.

Though is appears difficult it is deceptively easy to make. The steps are very similar to

the Double-Double Box Joint. The only difference is the use of a dovetail bit for the four

series of dovetail cuts followed by a straight bit for the final two series of cuts.

The depth

of cut is the same for both the dovetail bit and the straight bit.

BOXTAIL JOINTS

1. Select Stock Width

The decorative nature of the Boxtail Joint requires that certain stock widths be used in

order to produce a finished joint that is both visually pleasing and structurally sound. On

the full-size plan for each template pattern, there is a chart to help you select your stock

width and its corresponding symmetry mark. The selection of a stock width from this

chart then determines which series of cut lines will be used for the pin, tail and the two

middle section cuts. For example, if a lower symmetry mark is called for from your

selected stock width, any lower yellow diamond on template is a symmetry mark for

alignment to cursor.

If an upper symmetry mark is called for, any upper yellow diamond

on template can be used.

Note:

The 3/8” Boxtail requires two templates to complete all series of cuts.

Use template No. 32 (A) for all dovetail cuts.

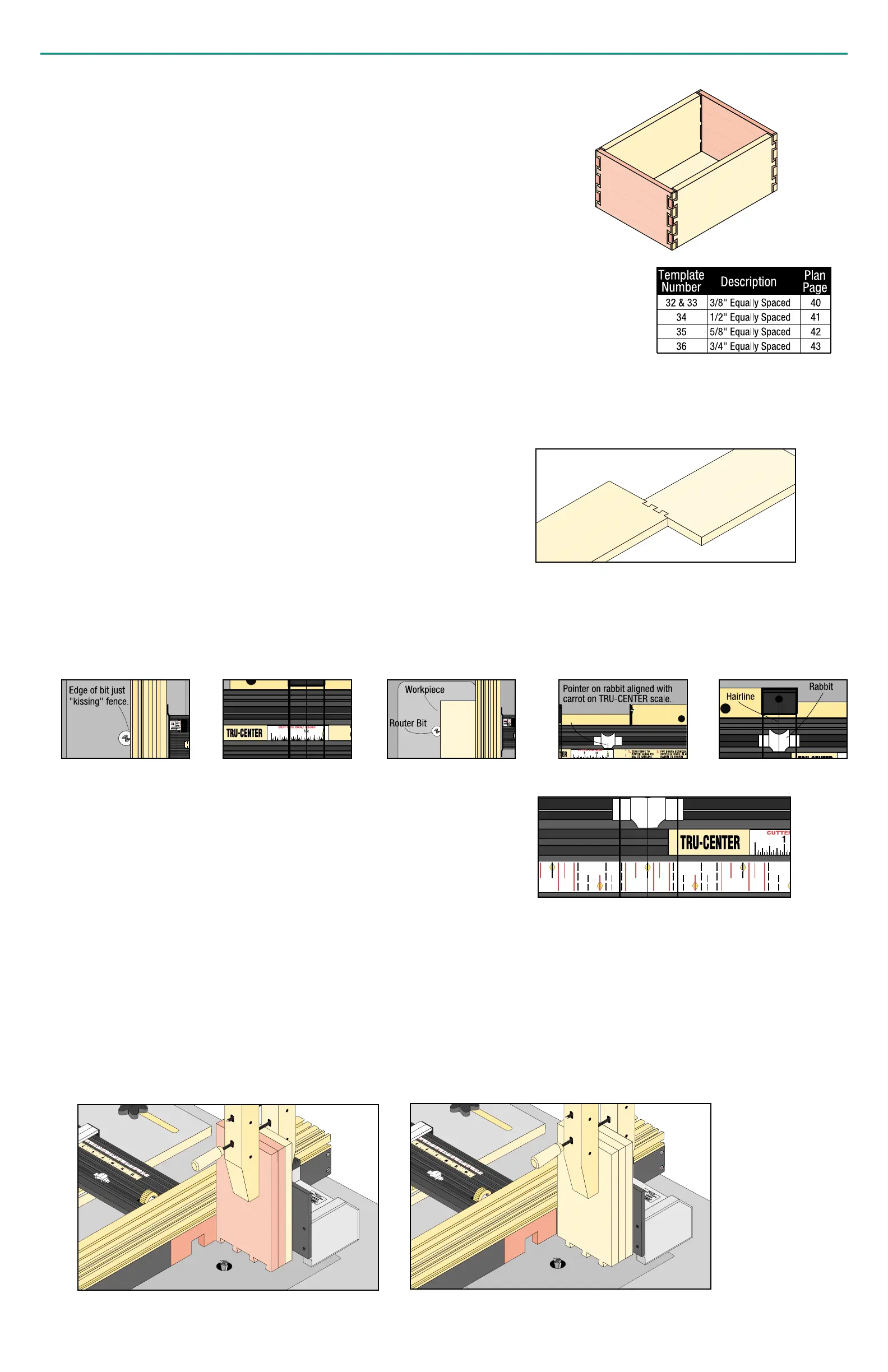

2. Set Depth of Cut

Find the depth of cut for your dovetail bit following the instructions in the

previous section on Half Blind Dovetails.

3. Center Board for Symmetry

Use the CLINCHER

Rabbit

and the TRU-CENTER scale to center the bit on your

workpiece following the instructions in the earlier Section on Making The Perfect Joint.

After finding center, lock carriage and install the selected template. Take one of your

workpieces and place a small pencil mark at its center on one end. You can do this by

placing it against the fence and up close to the bit.

4. Align Template

With Carriage locked and

Rabbit

still aligned to cursor, adjust the template in its slot until

one of the

symmetry

marks (upper or lower as pre-determined in step 1 from the

template’s Symmetry Chart) is in alignment with the cursor hairline. Be sure that there

will be enough cut lines to the left and right of cursor to make all the cuts over your board

width. You can quickly verify this by making a comparison of the center mark on your

board to the template and its position under cursor.

5. Making the Pins and Tails -

Dovetail Cuts

(Remember to include the middle-section wall thickness in length of boards)

Clamp your pin boards to the VPF with a backing board as shown. The backing board will

prevent splintering as the bit exits the cut. Install a stop block of fence to limit the travel of

the VPF to prevent damage to the fixture. Make the series of pin cuts. Flip the boards end

for end and repeat the same cuts. Now clamp the tail boards with a backing board to the

VPF and make its series of cuts on both ends. Note: The first cut on the tail board will be

an open cut meaning that you will be cutting away the edge of the board adjacent to the

fence. To prevent this first cut from splintering, make the cut in several small side by side

passes.

1. 2. 3.

5.

4.

22

Loading...

Loading...