LU-1560, 1565, 1560-7 (June, 2001) 1/4

LU-1560-7-0BB/XC-E500

LU-1560

(with an automatic lubricating mechanism)

LU-1565

(with an organized split needle bar)

LU-1560-7

2-needle, Unison-feed, Lockstitch Machine with Vertical-axis Large Hooks

(with an automatic lubricating mechanism

and an automatic thread trimmer)

Needle gauge*

4.8mm (3/16")

6.4mm (1/4")

7.9mm (5/16")

9.5mm (3/8")

12.7mm (1/2")

Pneumatic auto-lifter

Knee switch type (AK119A)

Pedal switch type (AK119B)

Not provided

● The new mechanism with a rectangular feeding motion

promises consistent feed of materials of all thickness without

the risk of stitch gathering.

The reduced lift of the feed dog helps prevent the material

from flopping and reduces operating noise and vibration.

〈Rectangular feed〉LU-1560, LU-1565, LU-1560-7

Compared with the elliptical feed, the rectangular feed helps

reduce gathered stitches.

● With the adoption of a new rectangular feed mechanism, an

alternating vertical movement mechanism, and a unison feed

mechanism, the machine can feed heavy-weight materials

powerfully and smoothly. Well tensed seams are consistently

produced without pitch errors.

● The machine has adopted a new mechanism that does not

change the ratio of alternate vertical movement of the walking

foot and presser foot even when the material thickness

changes.

Even when a heavy-weight material is used, the presser foot

lift does not decrease. This means that the presser foot

comes into contact with the material at exactly the same time

that it does when sewing lighter-weight sections of the

material. As a result, the walking foot retains the material

with a consistent pressure to prevent irregular stitches.

● LU-1560, LU-1560-7

• Automatic lubricating mechanism improves maintainability.

The sub oil pan and double filter prevent dust from entering

the oil.

● LU-1560-7

• The machine comes with JUKI's proven thread trimming

mechanism. With its robust knife and cam configuration,

the thread trimmer reliably cuts threads as thick as #5.

• The vertical strokes of presser foot and walking foot (their

alternating vertical movement) can be easily changed using a

large dial mounted on the top surface of the machine head.

• In addition the sewing speed is automatically adjusted with

the set value. With this feature, ideal sewing conditions are

maintained at all times.

● LU-1565

• The organized split needle bar mechanism makes it possible

to stop or reset the left or right needle by operating a one-

touch utility lever.

• The machine produces neatly finished stitches at corner parts

of the material.

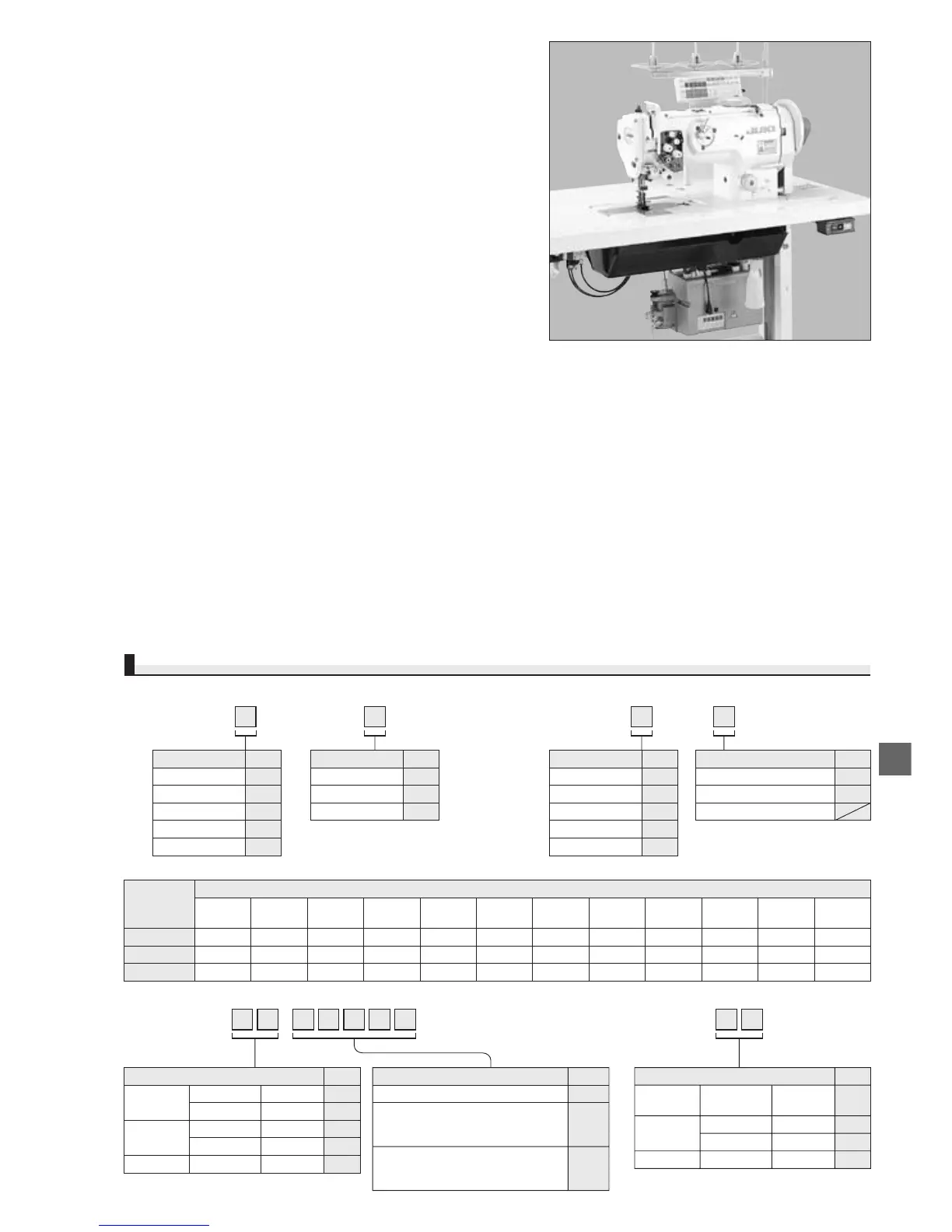

SC-380- -

● PSC box/control panel for SC ● Motor for SC

LU-1560 LU-1565

● Without an automatic thread trimmer

LU-1560 -7-0B

● With an automatic thread trimmer

M

Code

60

61

62

63

Motor

For General

Export

For JUS (LA)

For CE

For General

Export

For JUS (LA)

For CE

Single-phase

3-phase

Single-phase

3-phase

Single-phase

200〜240V

100〜120V

200〜240V

200〜240V

PSC box

Single-phase

3-phase

Single-phase

3-phase

Single-phase

220〜240V

200〜220V

110〜120V

220〜240V

220〜240V

Code

07

11

37

38

34

Code

D

F

H

K

L

Needle gauge*

4.8mm (3/16")

6.4mm (1/4")

7.9mm (5/16")

9.5mm (3/8")

12.7mm (1/2")

Code

D

F

H

K

L

Needle gauge*

4.8mm (3/16")

6.4mm (1/4")

7.9mm (5/16")

Code

D

F

H

Model name

LU-1560

LU-1560-7

LU-1565

Code

A

B

Code

00000

E500B

E500C

Control panel

Not provided

Control panel display language: English.

Instruction manual comes in three

different languages.

Control panel display language: English.

Instruction manual comes in five

different languages.

*

*

*JUS: North America and Central and South America.

*The needle gauge (attached with a circle (○)) in the table below are prepared as optional parts (separately available).

WHEN YOU PLACE ORDERS

Needle gauge

3.2mm 4.8mm 6.4mm 7.9mm 9.5mm 12.7mm 15.9mm 19.1mm 22.2mm 25.4mm 28.6mm 31.8mm

(1/8") (3/16") (1/4") (5/16") (3/8") (1/2") (5/8") (3/4") (7/8") (1") (1-1/8") (1-1/4")

○○○○○○○○○○○○

○○○○○○○○○○○−

−○○○○○−−−−−−

Loading...

Loading...