MOC-3900, MOF-3900 SERIES (June, 2001) 2/4

● For blind hemming ★L124: Blind hemming attachment ★L125: Blind hemming attachment (with automatic folded-edge control hemming device)

Note 1: Be sure to specify the built-in synchronizer when

the newly-developed servomotor is used with each machine.

Note 2: When the built-in synchronizer is installed on the

machine, the maximum sewing speed will be obtained by

subtracting 500 s.p.m. from the maximum sewing speed of

the machine head shown in the table above.

MOC-3904E-0△4-300

MOC-3904E-0F4-307

MOC-3904E-0△6-307

MOC-3904E-0F6-40H

L〜M

M〜H

1

1

1

1

3

3

3

3

–

–

–

–

3.2, 4.0

4.8

3.2, 4.0

4.8

2

2

3

3

3.5

3.5

3.5

3.5

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

6.5

7

7

7

DC×27 #11

DC×27 #11

DC×27 #11

DC×27 #11

8,500

8,000

8,000

7,500

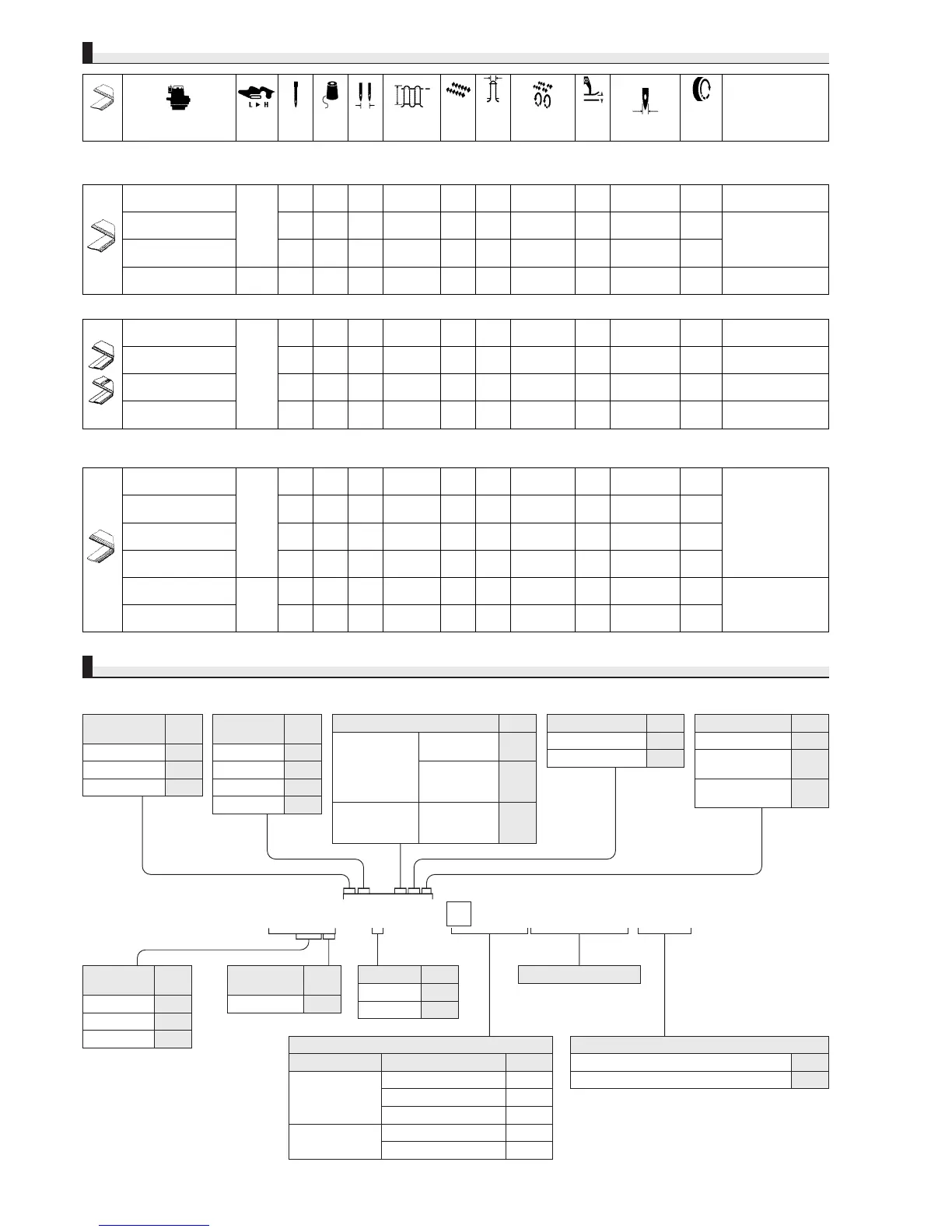

■ 2-needle overlock

● For runstitching

■ 1-needle overlock

● For runstitching

Upper looper

high throw type

MOC-3903E-0△4-210

/L124

MOC-3903E-0△4-210

/L125

MOC-3905E-0△4-210

/L124

MOC-3905E-0△4-210

/L125

L〜M

1

1

1

1

2

2

3

3

–

–

–

–

3.2, 4.0

3.2, 4.0

3.2, 4.0

3.2, 4.0

2

2

2

2

3.5

3.5

3.5

3.5

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

5.5

5.5

5.5

5.5

DC×27 #9

DC×27 #9

DC×27 #9

DC×27 #9

8,500

8,500

8,500

8,500

MOC-3914E-B△4-307

MOC-3914E-B△6-307

MOC-3914E-CE4-307

MOC-3914E-CE6-307

MOC-3914E-B△6-40H

MOC-3914E-C△6-40H

L〜M

M〜H

2

2

2

2

2

2

4

4

4

4

4

4

2.0

2.0

2.4

2.4

2.0

2.4

2.0, 3.2, 4.0

3.2, 4.0, 4.8

4.0

4.0

3.2, 4.0, 4.8

4.0, 4.8

2

3

2

3

3

3

3.5

3.5

3.5

3.5

3.5

3.5

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

1: 0.8〜1: 2.3

7

7

7

7

7

7

DC×27 #11

DC×27 #11

DC×27 #11

DC×27 #11

DC×27 #11

DC×27 #11

8,000

8,000

8,000

8,000

7,500

7,500

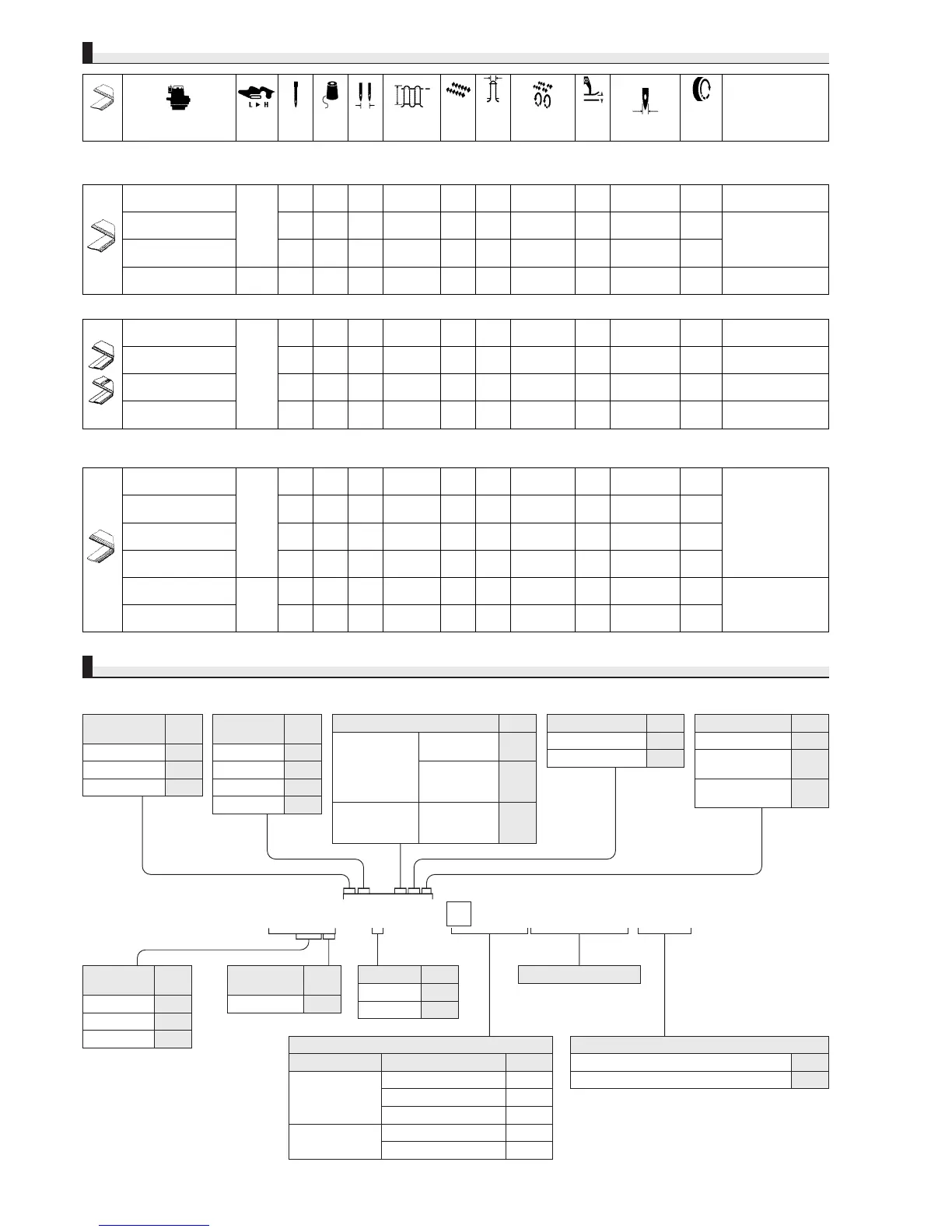

WHEN YOU PLACE ORDERS

(Note) Some combinations are not available.

M

O

C-3904E-0E6-307/ F /P02/Q01/T043/SY35

* No code is to be given to the standard square knife.

Specify the knife code, “F” or “W” only when a knife other

than the standard one is required.

Stitch type

in the U.S.A.

504

505

514

Code

04

05

14

Code

2

3

4

Code

0

1

Code

0

7

H

Symbol

K

F

W

P01〜

Q01

Special

specification

General spec.

Application

For runstitching

For blind hemming

Special machine

Standard

Upper looper high

throw type

Upper looper extra

high throw type

Needle gauge

(mm)

1-needle

2.0

2.4

Code

0

B

C

Overedging

width (mm)

2.0

3.2

4.0

4.8

Code

B

D

E

F

Built-in syncronizer

Maximum sewing speed of the machine head

8,000rpm

Code

SY35

Feed dog

2-row

3-row

Code

4

6

Code

E

Material

Device & attachment

For light- to

medium-weight

materials

For medium- to

heavy-weight

materials

Training wear,

knit, etc.

Standard

(for dress skirts

to sport wear)

Knit sweater,

bulky etc.

Gauges

Classification

Upper knife*

Replacement

gauge

Parts

Square knife

Flat knife

Corrugated square knife

Throat plate

Feed dog

SUBCLASS MACHINE LIST

Seams Model No.

*

Materials

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Overedging

width (mm)

Number

of

feed dog

rows

Max.

stitch

length

(mm)

Presser

lifting

amount

(mm)

Needle system

Max.

sewing

speed

(rpm)

Bottom

differential-

feed ratio

Remarks

Upper looper

extra high throw type

Upper looper

high throw type

Upper looper

extra high throw type

● For the machine attached with a triangle

(△), the number of kinds of overedging

width is two or more.

● The total overedging wigth:

Needle gauge + Overedging width

B – 2.0mm D – 3.2mm

E – 4.0mm F – 4.8mm

L = Light-weight materials

M = Medium-weight materials

H = Heavy-weight materials

*

Subclass Code

Model No. Code

Loading...

Loading...