AMS-210DHL6300SZ (September, 2003) 2/2

PROGRAMMING FUNCTIONS

● With its large memory, the machine responds to many different sewing patterns.

Sewing settings can be established and sewing patterns programmed entirely through the

operation panel.

● Ample storage capacity: maximum of 360,000 stitches on a floppy disk, or 691 patterns on

a 2DD disk or 999 ones on a 2HD disk.

● A maximum of 20,000 stitches can be input per pattern. With this large storage capacity,

the machine supports embroidery patterns with large numbers of stitches.

● A sewing pattern can be enlarged/reduced without changing the stitch length.

● Functions that are frequently used during pattern data input (regular stitching (linear,

spline), point stitching, jumping, thread trimming, etc.) are allocated to specific keys on

the operation panel. This reduces the time required for input of pattern data.

OPTIONS

WHEN YOU PLACE ORDERS

―

―

―

B5019-222-0B0

PJ-0320525-03

PJ-0205000-02

B4717-223-C00

BT040-025-1EB

BT060-040-1EB

B4712-215-0A0

SK-3312500-SE×2

SS-6151812-TP

WP-0641601-SD×5

B4720-215-0B0

―

B2593-210-DA0

B2594-210-DA0

B2585-210-DB0

B2586-210-DB0

M8607-580-AA0

PM-1

PGM-20

FU01L

―

―

MU12

―

―

―

Programming software for computer-controlled

sewing machines

Programming software for computer-controlled

sewing machines

Inverted clamp device for separately driven

pneumatic feeding frame

Thread tension controller No.3

Needle cooler

Milling unit

Cassette holder fixing base (asm.)

Cassette holder (asm.)

One-touch utility clamp for the monolithic

feeding frame

One-touch utility clamp for separately-driven

pneumatic feeding frame

I/O expansion unit

This software is to input and edit sewing data of JUKI's latest

sewing machines. Its versatile input functions allow to

input sewing data of each electronic sewing machine model

easily, accurately, and quickly. It supports high quality

production with high added value by utilizing and creating

original data for specific designs and applications.

The PGM-20 is provided with many different input functions

to permit interactive data creation, free from difficulties,

using a general-purpose personal computer or digitizer.

The pneumatically driven inverted clamp device is best

suited for the attachment of small parts of whose entire

peripheries need to be sewn such as labels and emblems.

The tension controller unit is used to partially change the

needle thread tension during the sewing of a pattern.

―

The milling unit can be installed on the machine to allow

the operator to easily machine a feeding frame or feed plate.

The next material to be sewn can be placed between the

top and bottom plates of the cassette holder while the

machine is still engaged in the sewing of the currently set

material.

The feeding frame and the feed plate can be quickly

changed without any tools.

The machine is provided with external input/output ports

that are very convenient when re-modeling the machine

with accessory devices attached.

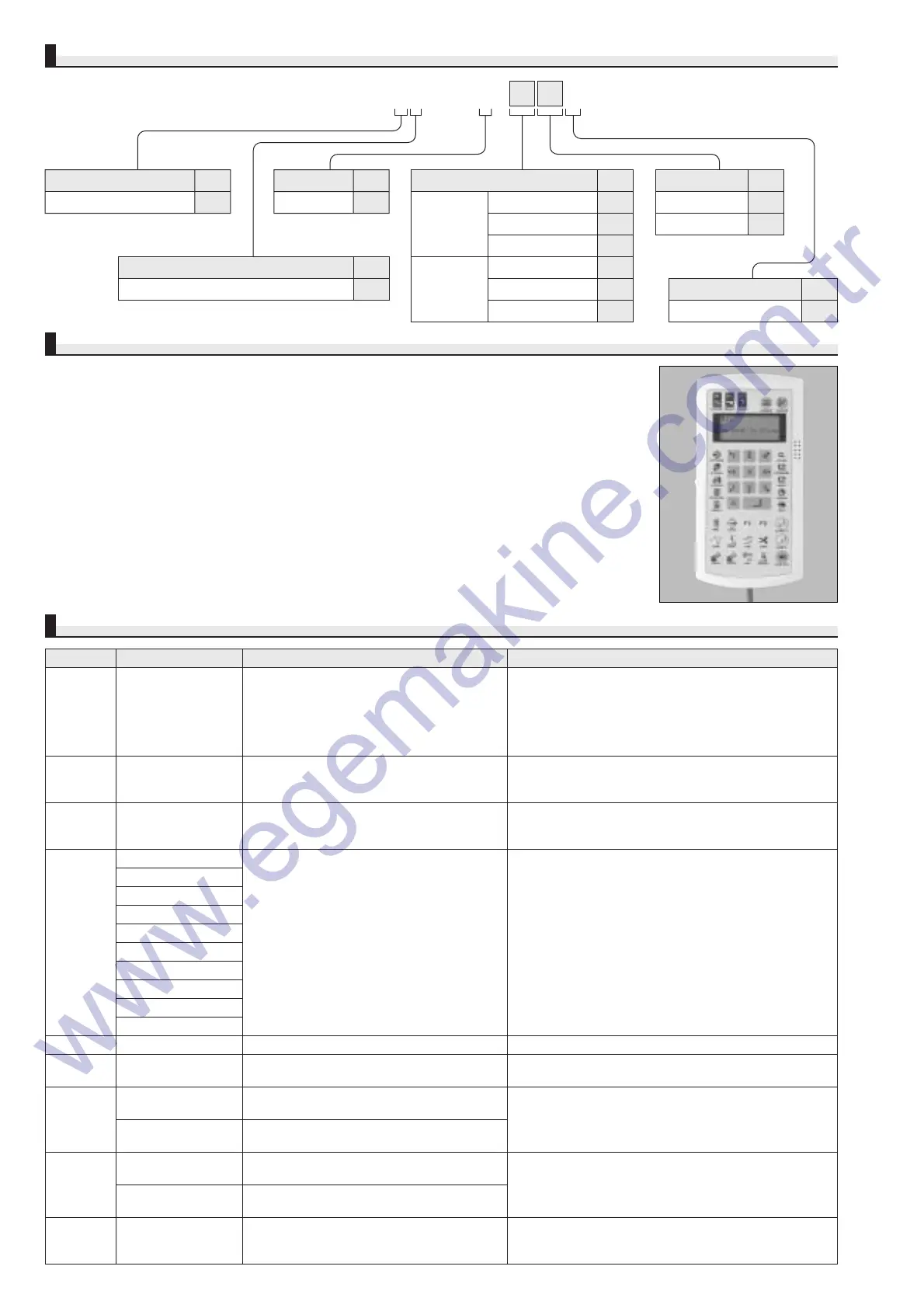

Model Part No. Description Feature

AMS210DHL6300SZ B

Application Code

For heavy-weight materials H

Stitch type Code

Standard S

Feeding frame type Code

Pneumatic separately-driven feeding frame L Control panel Code

English and pictograph B

Power supply Code

100〜120V C

Single-phase 200〜240V K

220〜415V R

200〜240V D

3-phase 220〜415V L

220〜415V (For CE) M

Pedal switch Code

3-pedal unit B

PK 3-pedal unit D

Loading...

Loading...