APW-297, 297B, 298 (September, 2003) 4/4

*The same optional parts are offered for the APW-297 and APW-298. They can be retrofitted to either machine.

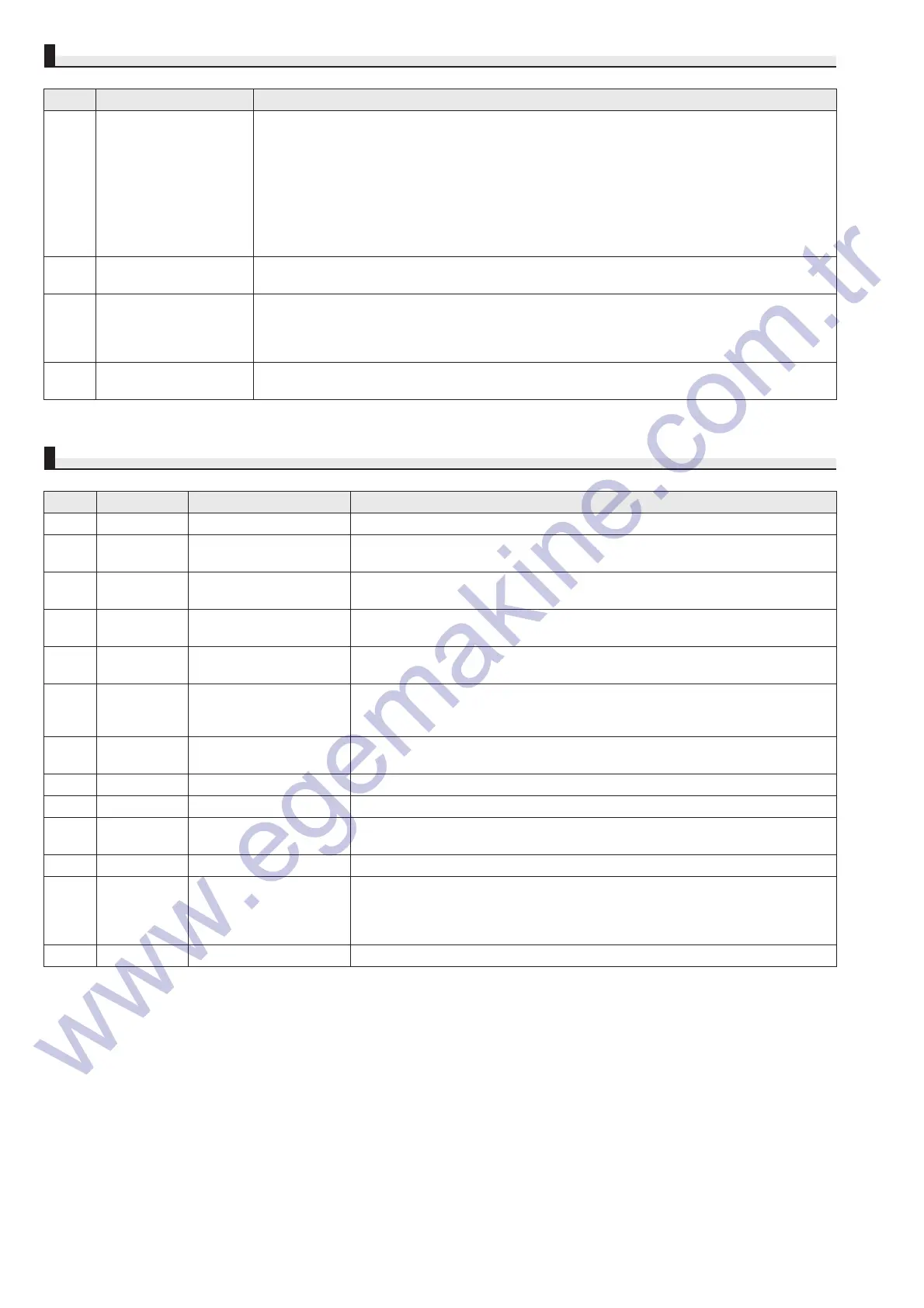

Model

SA73N

SA106

SA107

SA109

SA110

SA111

SA112

SA115

SA116

SA108

SA91

SP44

SP45

Part No.

GSA-730000A0B

GSA-106000A0

GSA-107000A0

GSA-109000A0

GSA-110000A0

GSA-111000A0

GSA-112000A0

GSA-115000A0

GSA-116000A0

GSA-108000A0

GSA-910000A0

―

―

Description

Auxiliary receiving plate (right)

Dart stretcher

Automatic pocket bag presser

Automatic interlining feeder

Stand for standing work

Right single-welt and double-

welt changeover device

Shim device

Automatic interlining presser

Table for vacuum type

Suction device

Suction motor

Clamp bar stacker

Roller stacker

Feature

This is the receiving plate for accessories for welting patches, etc.

The dart stretcher holds the end of the material when making a welt on a darted part of the

material to make it easier to set the darted part and improve the reliability of the welting.

The automatic pocket bag presser is used to hold pocket bags under the garment body when

welting and pocket bag sewing are performed concurrently.

To improve workability, the automatic interlining feeder automatically delivers rolled interlining

cloth onto the table and cuts it.

This stand is mounted under the main body of the machine to adjust the height of the main

body to standing work.

The device opens/closes the clamp foot by fingertip control. This enables easy changeover of

the sewing machine specification between double-welt and right-single-welt types simply by

changing the binder.

This device encloses a garment body between its upper and lower parts and feeds it to the

needle entry area. It is especially useful for difficult-to-feed garment bodies.

This device is used for securing interlining under garment body for sewing.

―

The device picks up the garment body by suction force to facilitate setting of materials on the

machine. Use the device with a suction motor (SA91).

This is the blower motor for the suction device (SA108).

Since the main body of the stacker swings around to catch a material, even smaller garment

bodies can be consistently stacked (350 mm from the pocket position at the minimum).

Stacked garment bodies are secured with the bar.

This prevents a stacked garment body from slipping down.

This is a stacker suited for small articles that cannot be feed by a bar stacker or grasping stacker.

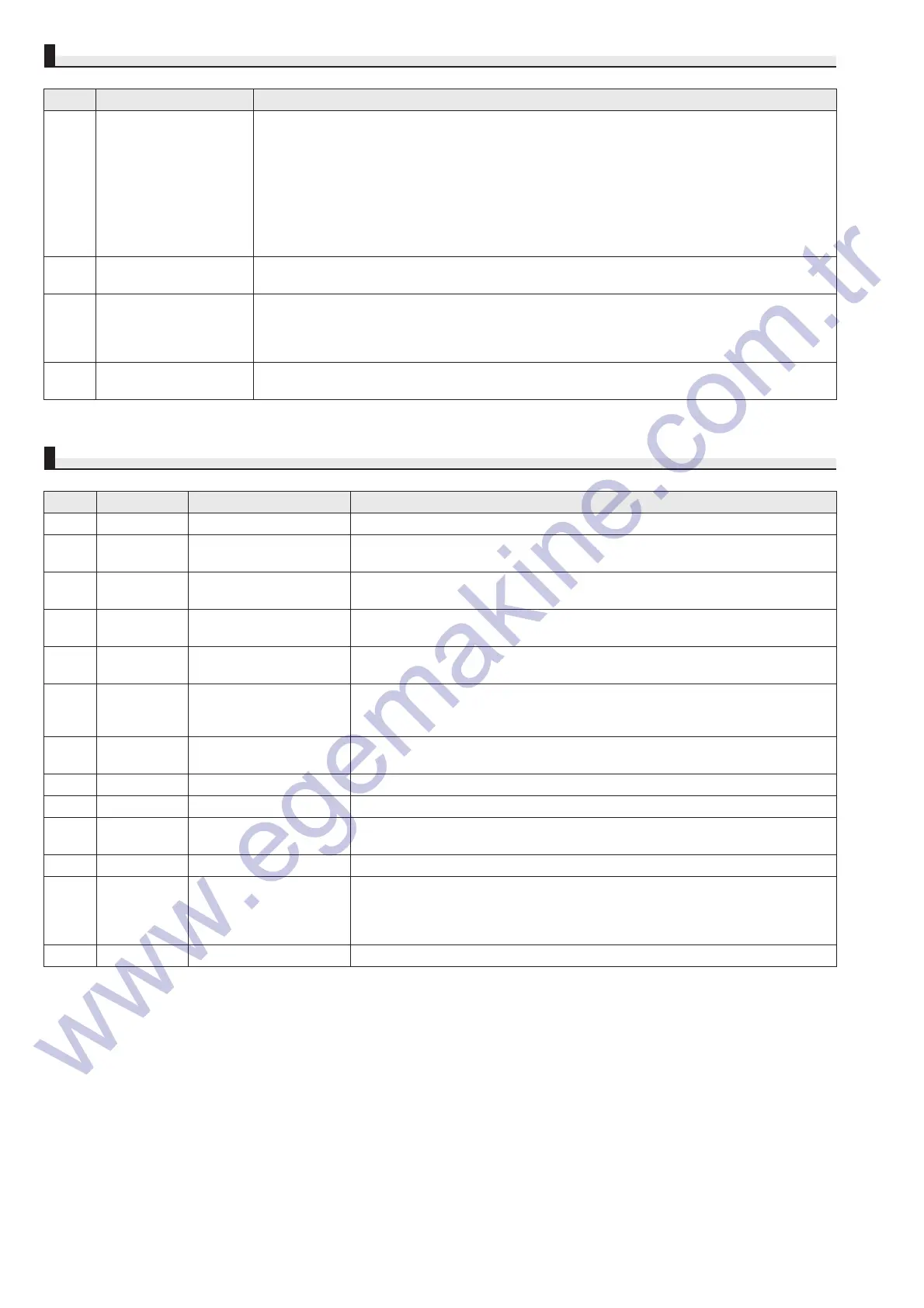

OPTIONS

Model

SA102

SA103

SA104

SA105

Description

Welting patch cutting device

Automatic flap feeder

Automatic flap and pocket

bag feeder

Automatic pocket bag feeder

(right)

Feature

•The knife is motor-driven. To cut the welting patch as short as possible, it automatically adjusts itself to the

sewing length established on the operation panel. This enables more consistent welting patch feed and folding

operations.

•The welting patch cutting knife is located under the welting patch table. This keeps the knife from damaging the

garment body. In addition, the knife can be changed with ease.

•Welting patch cutting, a job conventionally done by hand in the after-process, is no longer required. The result is

a substantial reduction in the processing time.

•The clamp exclusively used during welting patches cutting allows the cutting device to cut welting patches even

when the binder is in the lower position. This further eliminates wasted time due to welting patch cutting.

•The fulcrum at the center of the automatic flap feeder claw clamps flaps securely and automatically feeds them to

the sewing position. This promises increased productivity.

•The device works to sew the flap and pocket bag at the same time with the pocket bag placed on the flap.

•Simultaneous sewing of a flap and pocket bag produces beautifully finished welts free from uneven material feed.

In addition, there's no longer any need to attach the pocket bag on the flap side, a task normally required in the

after process.

•This device is intended to be used with SA104 (automatic flap and pocket bag feeder) to automatically sew pocket

bags on both sides of a welting patch.

NEWLY DEVELOPED DEVICES (OPTIONAL)

Since optional parts can't be retrofitted to the machine after purchase, be sure to specify any that you may need when placing your order.

Loading...

Loading...