DDL-8700, 8700-7 (September, 2003) 2/2

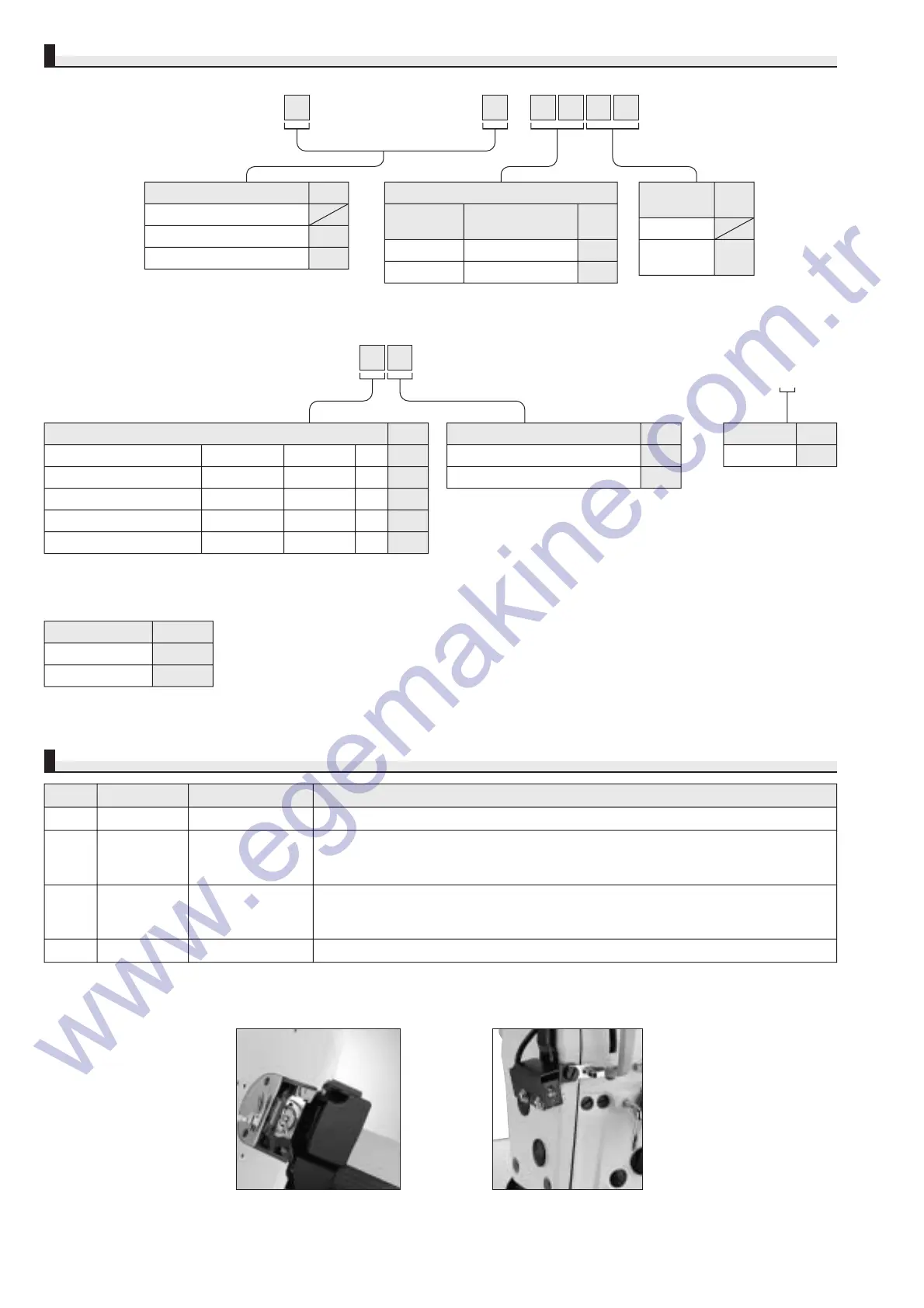

Remaining bobbin thread detector (AE-4) Material edge sensor (ED-2)

DDL8700 7

Application

For medium-weight materials

For light-weight materials

For heavy-weight materials

Code

A

H

Code

Auto-lifter

(optional)

Not provided

Provided

(AK85)

AK

WHEN YOU PLACE ORDERS

OPTIONS

DDL8700

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

Model

AK85

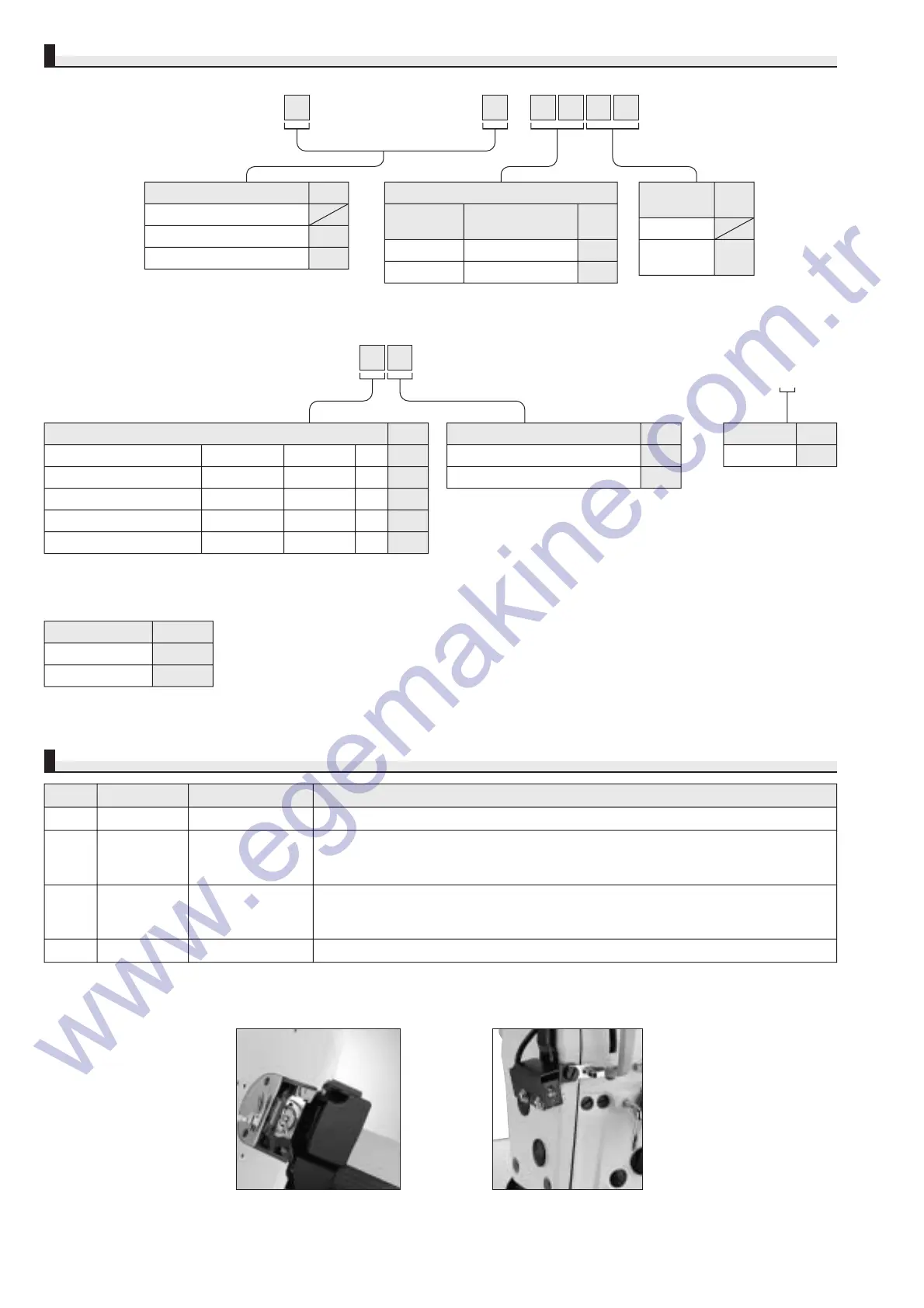

AE-4

*

ED-2

―

Part No.

―

GAE-040000A0

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Micro-lifter (asm.)

*To retrofit the AE-4 to your existing machine, I/O unit A (part number: 400-06080), which is separately available, is required.

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press on the front part of the foot pedal. With this function, the operator

doesn't have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

This device can be installed on the back of the faceplate. It is very convenient for frequent use.

SC910

M91S

● PSC box ● Motor for SC

● Operation panel

Operation panel Code

IP-100C IP100C

CP-160A CP160A

Control box Code

Standard S

Provided with built-in I/O board A

Pulley belt Code

Standard S

● Control box provided with built in I/O board

(Code A) should be selected for the machine

head equipped with the remaining bobbin

thread detector (AE-4).

PSC box Code

For JUS (LA)

*

Single-phase 100〜120V PFL S

For JUS

*

, General Export 3-phase 200〜240V PFL D

For General Export Single-phase 200〜240V PFL K

For EU (CE) Single-phase 200〜240V PFL N

For China Single-phase 200〜240V PFL U

*JUS: North America and Central and South America.

Loading...

Loading...