LZ-2290A Series (September, 2003) 2/4

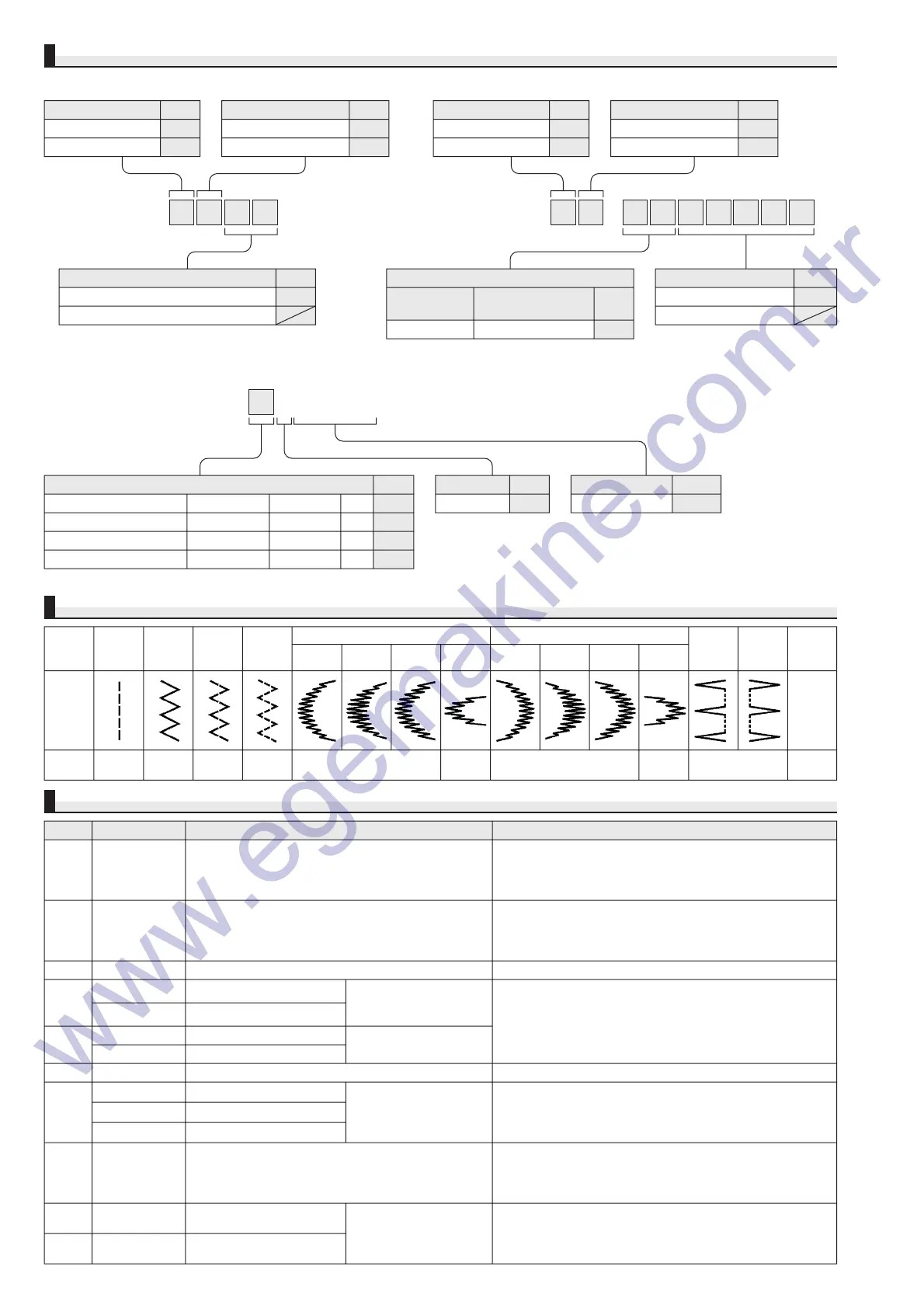

WHEN YOU PLACE ORDERS

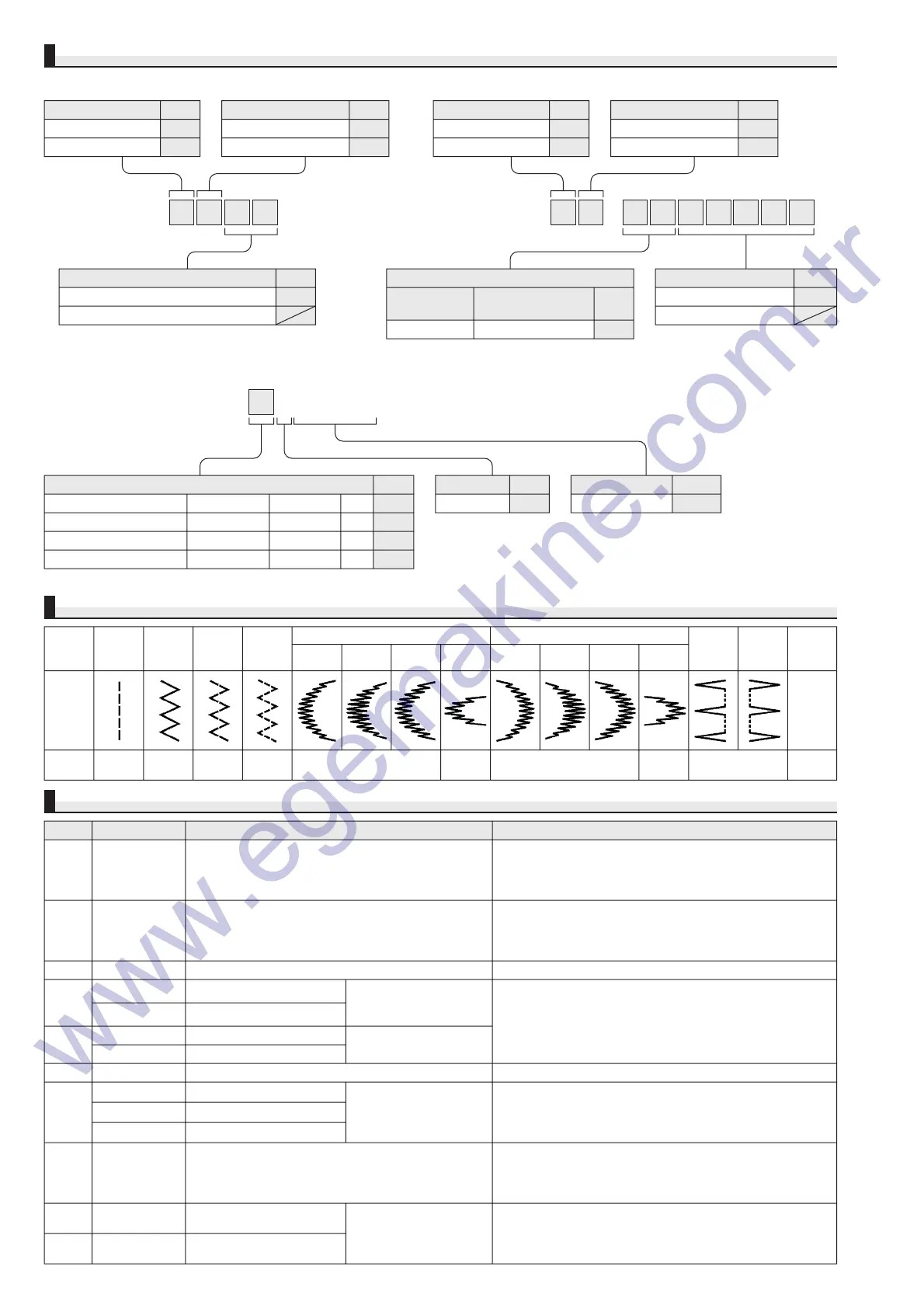

SEWING PATTERN

LZ2290A LZ2290A 7

SC915 SIP100A

● Without automatic thread trimmer

● PSC box/Operation panel for SC

● With automatic thread trimmer

Control box Code

Standard S

Operation panel Code

IP-100A IP100A

Machine head type Code

Standard S

Dry-head D

Machine head type Code

Standard S

Dry-head D

Type Code

Standard S

Anti-material-slip type U

Type Code

Standard S

Anti-material-slip type U

Push-button-type reverse feed switch Code

Provided 0B

Not provided

For LZ-2290A-SU (anti-material-slip capability),

select "Not provided."

Device/Attachment Code

Auto-lifter (pedal-driven) AK121

Not provided

PSC box Code

For JUS

*

Single-phase 100〜120V PFL C

For JUS

*

, General Export 3-phase 200〜240V PFL D

For General Export Single-phase 200〜240V PFL K

For CE Single-phase 200〜240V PFL N

* JUS: North America and Central and South America.

Wiper/Push-button-type reverse feed switch

Wiper

Push-button-type

reverse feed switch

Code

Provided Provided WB

OPTIONS

Model Part No. Description Features

− 400-10795 Automatic reverse feed kit

− 400-03640 Optional switch kit

AK121 GAK-A21000B0 Auto-lifter (pedal-driven) −

−

D1501-583-H00 Presser bar

D1502-583-H00 Presser connecting rod

−

B1551-586-000 Presser foot connecting foot

SS-7090910-SP Screw

− 225-26560 Hard-point hook

235-23152 Hook

− 235-22550 Bobbin case(asm.)

235-23004 Bobbin

V059 MAV-059000AA Tension-free feeder (Tape feeder)

S189A MAS-189000AA Pneumatic type

S189B MAS-189000AB Solenoid type

Presser foot connecting

components

(Replaceable presser bar)

Presser foot connecting

components

Hook with

non-rotational bobbin

Elastic tape tensing device

When this device is installed, the LZ-2290A-□□(without

automatic thread trimmer) can perform reverse feed operation.

(The mirroring switch for scallop stitching is used as the push-

button-type reverse feed switch.)

This handy switch is used to control various functions

*.It is

most effective when operating the machine in a standing

position. (*Needle up/down correction, 1-stitch correction, reverse-

stitch correction, auto lifter and thread trimmer, etc.)

The aforementioned parts are used when a lockstitching type

presser foot is installed on the machine.

The blade point of this hook prevents abrasion.

The hook with non-rotational bobbin eliminates sewing troubles

resulting from bobbin idling. It provides a uniform bobbin

thread tension at all times, thereby guaranteeing a consistent

stitch formation.

The amount of tape to be fed can be adjusted in accordance

with the sewing speed of the machine. It is adaptable to

processes for attaching reinforcement tape, attaching elastic

tape or lace to foundation.

Applies tension to desired portions of the tape fed from tension-

free tape puller. The device is started/stopped by operating the

knee switch. This increases operator productivity without

interrupting the sewing work.

Name of

pattern

Stitch

pattern

Number of

stitches

1246 24

Straight

stitch

Standard

zigzag

2-step

zigzag

3-step

zigzag

Standard Crescent

Equal-

width

Equal-

width

Standard Crescent

Equal-

width

Equal-

width

Scallop (left) Scallop (right) Blind

stitch

(left)

Blind

stitch

(right)

Custom

pattern

12 24 12 2 + α

Max. 500

Loading...

Loading...