–

76

–

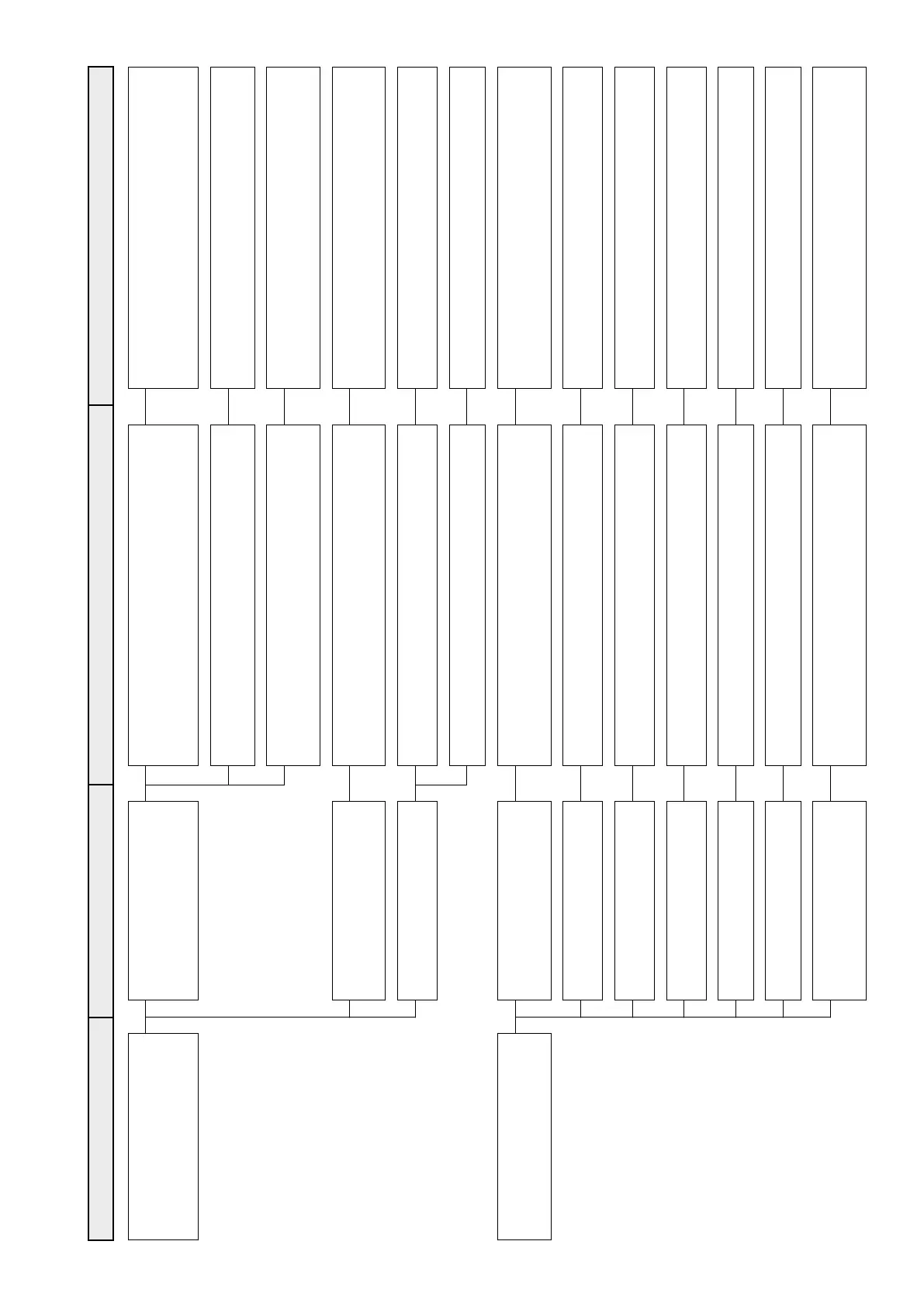

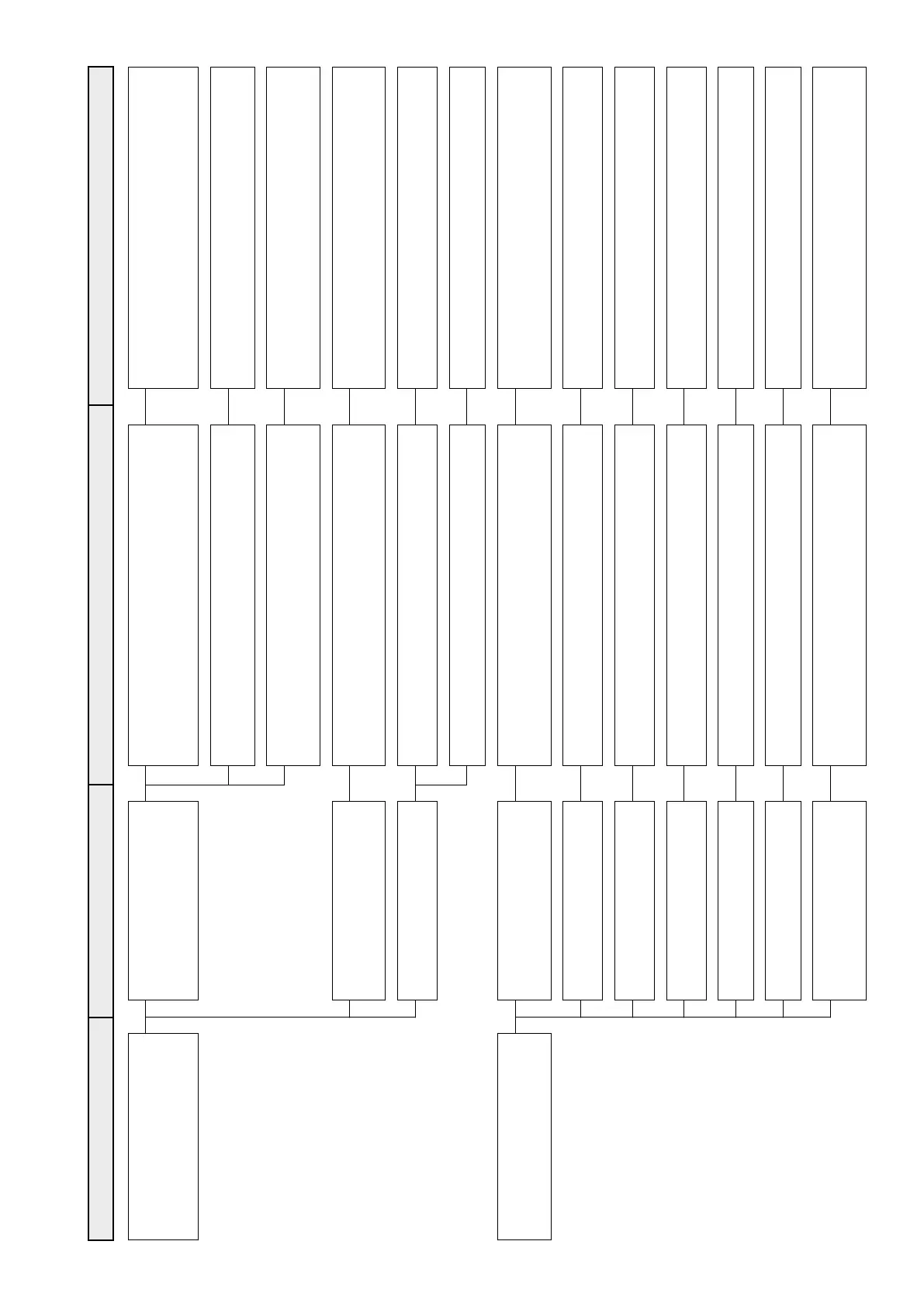

Trouble Case (1) Case (2) Check and Corrective measures

2. Looper thread breakage 2-1) Thread path 1-A) Scratches, burrs, rust, etc, on the paw of

the throat plate, stitch tongue, looper, looper

thread take-up, thread guide, or tension

discs causes friction.

Remove such scratches, burrs, etc. and carry

out thread path nishing. Replace loopers or

other components which have been deformed,

causing thread breakage.

1-B) Burrs and scratches on the end face of the

thread path pipe.

Deburr or remove scratches from the end face

of the pipe.

1-C) Scratches on the inside of the pipe. Pass the thread to the looper. Then, pull the

thread by hand to check whether the thread is

caught inside the pipe.

2-1) Adjustment of the

looper thread take-up

2-A) The looper thread take-up or thread guide

has been improperly positioned, causing

excessive thread tension.

Refer to the pertinent Standard Adjustment.

2-3) Thread tension 3-A) The looper thread tension is too high. Reduce the tension while checking the tension

balance other looper thread.

3-B) The thread tension controller is poorly ad-

justed.

Adjust the thread tension controller so that the

standard thread tension is obtained.

3. Needle breakage 3-1) Needle entry 1-A) The needle entry has not been correctly

adjusted, and the needle strikes the throat

plate or presser foot.

Correct the needle entry.

3-2) Upper looper position 2-A) The upper looper juts out too much or it is

too low.

Refer to the pertinent Standard Adjustment.

3-3) Contact with the loop-

er

3-A) The needle strikes the looper, resulting in

needle breakage.

Adjust the looper so that it does not strike the

needle.

3-4) Needle guards 4-A) A needle guard has been improperly posi-

tioned, causing the needle point to strike it.

Refer to the pertinent Standard Adjustment.

3-5) Needle No. 5-A) The needle is too thin for the materials. Replace the needle with a thicker one.

3-6) Thread tension 6-A) The thread tension is too high. Reduce the thread tension.

3-7) Height of the feed dog

or needle

7-A) The feed dog is too high, or the needle is

too low, causing the needle to deect with

resultant needle breakage.

Refer to the pertinent Standard Adjustment.

Loading...

Loading...