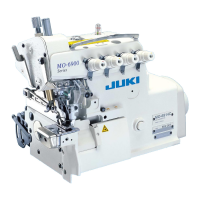

MO-6914C

MO- 6 904C

Since the machine comes with a needle-thread

take-up mechanism as well as a looper thread

take-up mechanism, to enable sewing with a

lower tension applied to the material, it achieves

soft-feeling high-quality seams.

New and powerful machine for

sewing tubular materials !

The MO-6900C Series sewing machine,

provided with a small-in-diameter cylinder bed,

is capable of runstitching or blind-hemming

tubular materials, such as sleeve cuffs, with

ease. The operator can carry out sewing of the

tubular material while turning it downward.

This promises improved workability and

contributes to dramatically increased productivity.

The machine ensures both

beautiful and upgraded seam

quality at higher speeds.

The introduction of a shield-structured needle

bar mechanism and upper and lower needle bar

bushings, contributes to increased durability and

reliability. The machine is provided as standard

with a cartridge type oil filter and cooling fan,

thereby ensureing enhanced reliability.

Further increased reliability.

To offer improved sewing capabilities

as well as to prevent stitching

mishaps during high-speed sewing,

the machine is provided as standard

with the needle thread heat remover

and needle cooler.

The needle thread heat remover and needle cooler are

equipped as standard.

The cylinder bed is bestsuited to the

runstitching and blind hemming of tubular

materials. Gauges and devices you have

used with your existing JUKI machines are

also interchangeable with no additional

machining required. This eliminates both

the waste of resources and unwanted

extra costs.

Small-in-diameter cylinder bed.

Since the machine is provided as standard with the bottom feed dog inclination-

adjusting mechanism and the external differential feed-increasing mechanism, it

can be easily adjusted to ideally match the material being sewn. In addition, the

machine is provided as standard with a micro lifter feature that offers improved

responsiveness to materials, and provides the operator with upgraded operability.

The stitch length can be easily adjusted with the push-button mounted on the

front surface of the sewing machine.

Mechanisms that promise improved operability.

Needle cooler

MO-6904C-0D6-307 1 3 − 3.2 3 3.5 1:0.8〜1:2.3 7 DC×27 #11 8,000

MO-6904C-0E6-307 L〜M1 3 − 4.0 3 3.5 1:0.8〜1:2.3 7 DC×27 #11 8,000

MO-6904C-0F4-307 1 3 − 4.8 2 3.5 1:0.8〜1:2.3 7 DC×27 #14 8,000

■ SUBCLASS MACHINE LIST

■ DEVISES AND ATTACHMENTS

< 1-needle overlock >

Seams Model No.

Materials

Number

of

needles

Number

of

threads

Needle

gauge

(mm)

Overedging

width (mm)

Number

of

feed dog

rows

Stitch

length

(mm)

Presser

lifting

amount

(mm)

Needle system

Max.

sewing

speed

(sti/min)

Bottom

differential-

feed ratio

Remarks

Upper looper extra high

throw type

MO-6914C-BD4-307 2 4 2.0 3.2 2 3.5 1:0.8

〜1:2.3 6.5 DC×27 #11 8,000

MO-6914C-BD6-307 L〜M2 42.0 3.2 33.5 1:0.8〜1:2.3 6.5 DC×27 #11 8,000

MO-6914C-BE6-307 2 4 2.0 4.0 3 3.5 1:0.8〜1:2.3 6.5 DC×27 #11 8,000

< 2-needle overlock >

Upper looper extra high

throw type

Chain-off thread trimming device

Model Part No. Description

T043 MAT-0430000A0 Pneumatic side cutter

Pneumatic chain-off thread suction device

MC-38 ― Pneumatic chain-off thread + cloth chips

MC-39 ― Function of MC-8 + auto-lifter

Auto-lifter

AK93 GAK-930000A0 Pneumatic type (knee-operated)

AK94 GAK-940000A0 Pneumatic type (with chain-off thread suction device)

AK102 GAK-A02000A0 Pneumatic type (for servomotor)

― PF-0552010-B0 Air regulator (F.R. unit asm.)

― GMD-01080000×2Fixing screw for F.R. unit asm.

― F1021-003-000 Tube connector (male)

― GAS-12063000

*

One-touch connector

*Selection parts instead of the tube connector

MC-7B ―

Blower-type chain-off thread suction device + cloth chips

Blower-type chain-off thread suction device

[Reference]

Combination table of “chain-off thread suction device” and

“auto-lifer” which correspond to “chain-off thread trimming device”.

Chain-off

thread

trimming

device

T043

Chain-off

thread

suction

device

Auto-lifter

MC-7B AK102

(JUKI servomotor)

*―

AK94

(any motor will do)

*AK94 is equipped with chain-off thread

suction device.

MC-38 AK102

(JUKI servomotor)

MC-39 ― (MC-39 is equipped with auto-lifter.)

*The aforementioned devices are not equipped with air regulator.

Please purchase the following components when you need to regulate air pressure.

Blind hemming device

L124 MAL-124000A0 Blind stitch hemming attachment A ruler used for blind hemming in knits

MAL-125001A0 For 110, 115, 220, 240V

L125

MAL-125002A0 For 220, 380, 415, 440V

MAL-125001AA For 110, 115, 220, 240V

MAL-125002AA For 220, 380, 415, 440V

Automatic

folded-edge

controlled blind

hemming device

For flat

upper knife

For square

upper knife

Model Part No. Description Feature

The attachment automatically detects the overlapped section of a material.

Then, it makes the needle enter the material deeper to prevent stitch deviation.

Ruler, Miscellaneous

H153 MAH-153000A0 Cloth edge guide ruler A swing type edge guide.

― 122-26155 Cloth plate Wider material can be sewn by attaching the cloth plate.

Cloth tensioner

TR01 ― Small-diameter roller for rib attaching

TR02 ― Large-diameter cloth tensioner

* “sti/min”stands for “Stitches per Minute.”

Loading...

Loading...