– 8 –

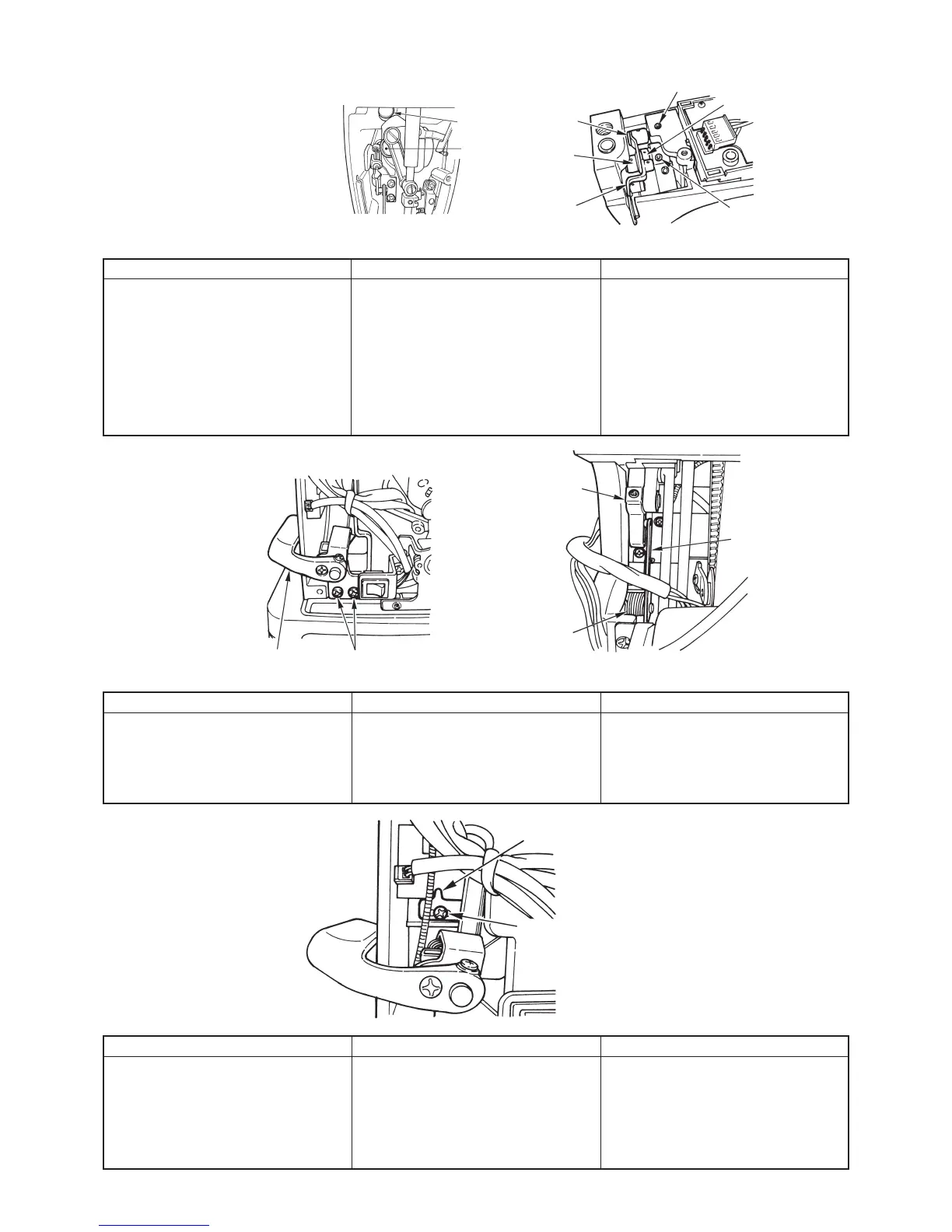

7. Reverse feed stitch lever

Preparation

™ Remove belt cover.

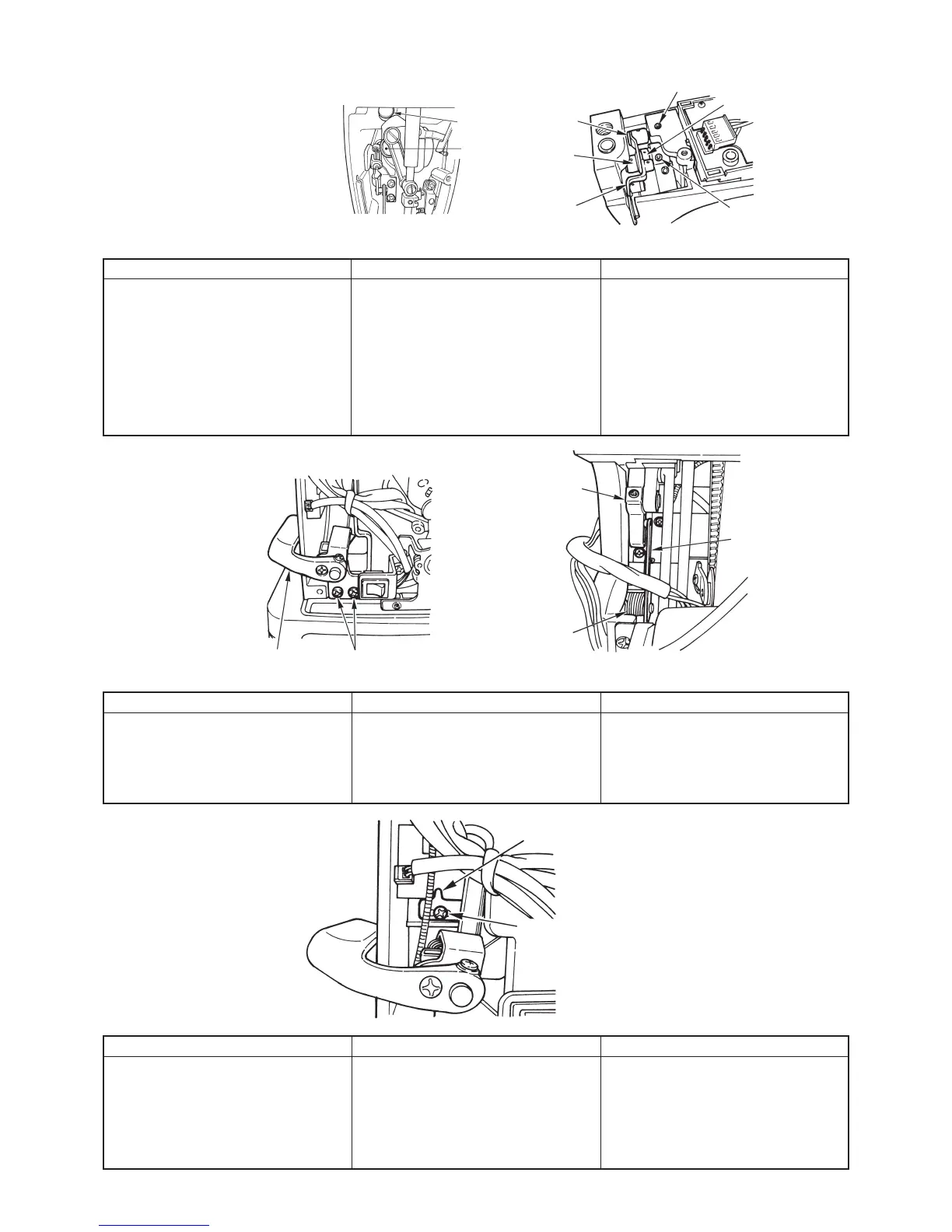

8. Idler

Preparation

™ Remove belt cover.

Disassembly

™ Remove 1 setscrew and remove

idler asm.

Assembly

™ Assemble idler and tighten it with

1 setscrew.

™ Belt tension : Belt sags 6 to 7 mm

when center of the belt is applied

with a 1.96N load.

Point

™ Belt tension can be changed only

by removing belt cover. Move 2

convex portion to the left or right.

Disassembly

™ Remove 1 spring from arm.

™ Remove two 2 setscrews.

™ Remove 4 lever arm from the slot

of 5 regulator when removing 3.

Assembly

™ Attach 3 lever and set with 2

setscrews.

™ Hook lever spring 1 to lever arm

4.

Point

™ Set 4 lever arm to the slot of 5

regulator.

Disassembly

™ Loosen 1 setscrew.

™ Loosen two 2 setscrews.

™ Draw out thread 3 take-up

supporting shaft.

™ Remove 5 and 6 together with

4 needle bar crank.

Assembly

™ Set needle bar crank to thread

take-up, attach it onto main unit

and tighten setscrews (2 pcs.).

™ Set 6 to 5, enter thread take-up

supporting shaft 3 to 6, attach it

onto frame and tighten 1

setscrew.

Point

™ Tighten setting portion (flat

portion) of needle bar crank with

screw No. 1.

™ Press 3 shaft to frame side while

viewing the torque and tighten 1

setscrew.

6. Thread take-up

Preparation

™ Remove arm cover asm.

™ Remove face plate mas. asm.

™ Remove presser bar.

™ Remove needle bar.

2 Convex portion of idler installing plate

1 Idler setscrew

SM5040855SN

5 Feed regulator

1 Reverse feed

stitch lever spring

4 Reverse feed

stitch lever arm

2 Needle bar

crank setscrew

5 Thread take-up

1 Thread take-up supporting shaft setscrew

SM8050602TP

3 Thread take-up

supporting shaft

4 Needle bar crank

6 Thread take-up

support

3 Reverse feed stitch

lever mas. asm.

2 Reverse feed stitch lever

setscrew SM5040855SN

Loading...

Loading...