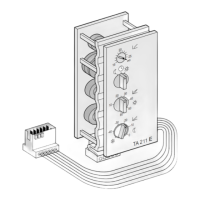

TA 211 E

12

English

With the installation of the TA 211 E Regu-

lator, the electronics of the heating unit au-

tomatically use the pump switching type III

(continuous pump operation), also when

the factory setting was not changed!

The figures and are schematics of the

application of the TA 211 E with radiator and

floor heating systems.

The corresponding electrical connection dia-

gram (Figure to ) is to be used.

Legend for the Figures to

:

P

I

Circulation pump

SF Storage temperature sensor (NTC)

B

2

Mechanical flow temperature limiter

(only in connection with underfloor

heating systems)

AF Outside temperature sensor

WS Warm water storage

RK Check valve

E Venting valve

5.1 Electrical Connection of the Outside

Temperature Sensor (AF)

• Remove the cover (AF

c

with AF

b

, Fig. ).

• Insert the cable through the threaded

fitting (AF

d

) and connect to the two termi-

nals (AF

e

).

• Tighten the threaded fitting (AF

d

) so that

strain relief and splash water protection is

provided at the cable feed-through.

• Close the outside sensor.

• On the boiler, insert the cable through the

protective sleeve and secure with the strain

relief.

• Connect the cable to the TA 211 E on the

terminals “A” and “F” (Figure to ).

5.2 Electrical Connection of Accessories

(Figure to )

5.2.1 Time Switch

• Connect the time switch (if available) ac-

cording to Figure on the main circuit

board of the boiler to connector ST 5 .

5.2.2 Remote Control (not in UK)

• Connect the TW 2 Remote Control

(in case available) on the TA 211 E to the

terminals 3 and 4 (Fig. ).

• Connect the TFQ 2 T, TFQ 2 W or TFP 3

Remote Controls (in case available) to the

terminals 1, 3 and 4 (Fig. ).

5.2.3 Mechanical Flow Temperature

Limiter

• An additional mechanical flow temperature

limiter is to be connected to the feed of floor

heating systems. The electrical connection

is to be made according to the installation

instructions of the heating unit.

5.3 Closing the Switching Box

• Replace the cover (h) and screw in the

screw (g, Fig. ).

• Snap in the cover (f, Fig. ).

6 Placing into Operation

By operating the boiler, the TA 211 E Regula-

tor is also activated.

7 Operation of the Regulator

Legend for the Figures and :

a

I

Outside temperature for boiler switch-

ing off point

b Operating Mode Switch

c Base point

d Night Reduction

e Maximum flow temperature

VT Flow temperature

AT Outside temperature

MVT Average feed temperature

6 7

8 10

6 10

3

8 10

8 10

8

9

Loading...

Loading...