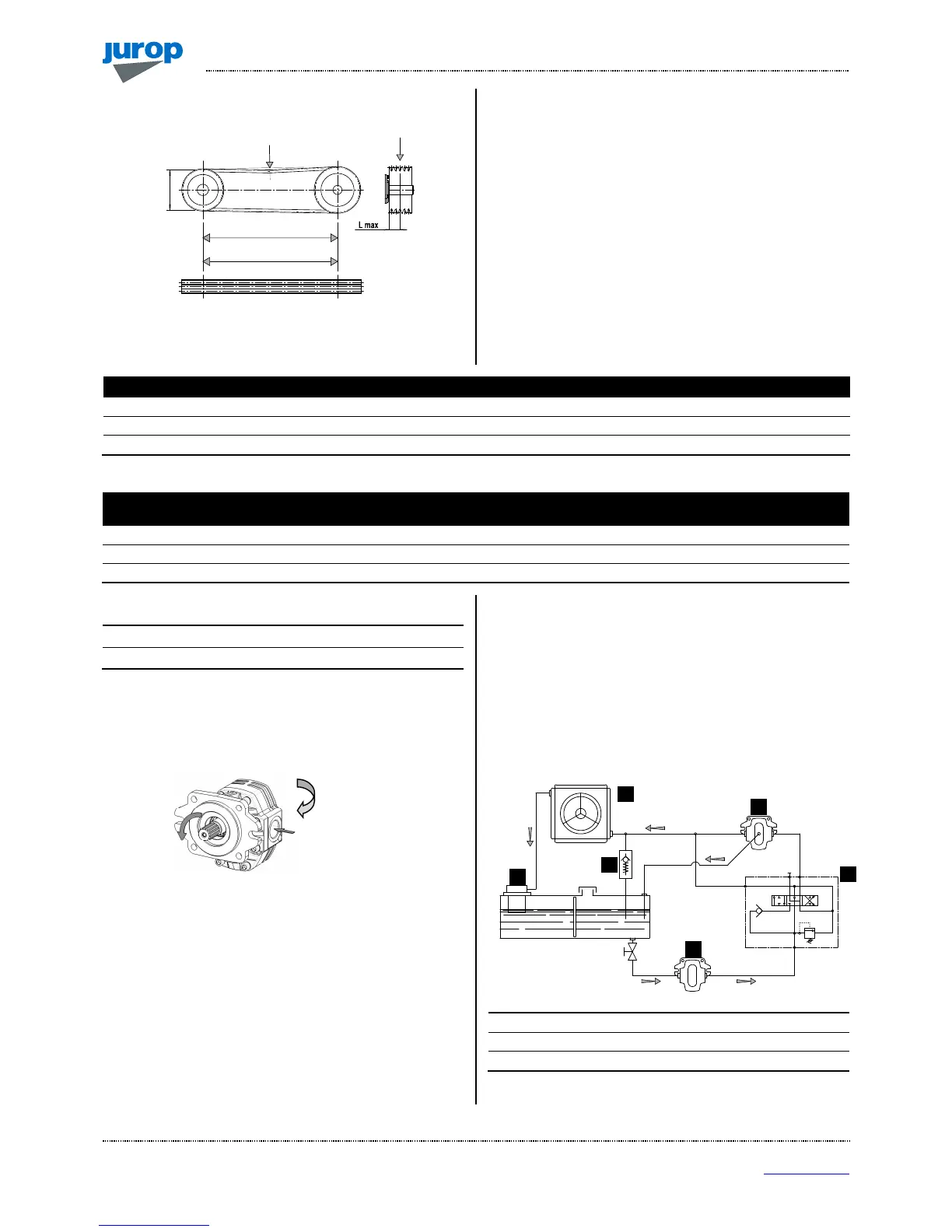

B) Belt drive

Pic. 4.7

• Install a suitable pulley on the smooth shaft as close as possible

to the pump: max 35 mm.

• Apply an adequate belt tension (see manufacturer’s data). Max

3000N.

• Do not use driven or driving pulleys with a pitch diameter inferior

to 180 mm. Small pulleys require a high belt tension which may cause

premature wear to the bearing or transmission troubleshooting.

• A limited speed ratio allows a longer belts life while reducing

stress on the shafts. When possible, prefer:

- Pulleys with a pitch diameter bigger than the one indicated;

- Motors or power take-offs with a speed similar to the one of the pump.

Pump Drive min. pulley p. diam. T. max Belts Max. Speed Max. Pressure Max. Vacuum.

LC300 180 mm 3000 N SPB x 3 1300 rpm 2 bar abs 92%

LC420 180 mm 3000 N SPB x 3 1300 rpm 2 bar abs 92%

LC580 180 mm 3500 N XPB x 3 1200 rpm 1,5 bar abs 95%

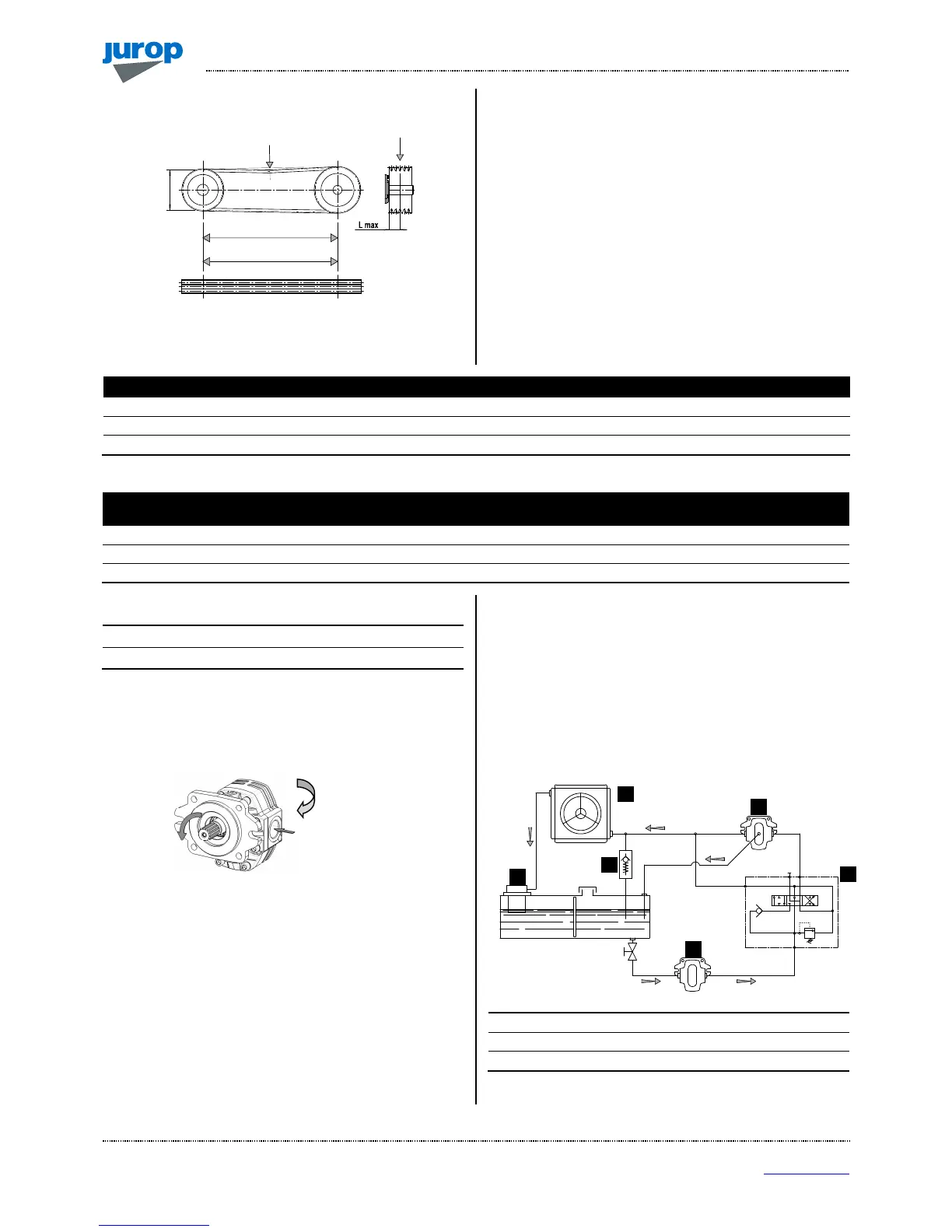

C) Hydraulic drive

Model Displacement

Operating pressure

(max. vac.)

Operating pressure

(1 rel. bar)

Flow

Max pressure

draining line

Max. pressure

motor exhaust

Max pressure

LC300 61 cc/rev 125 bar 150 bar 83 l/min (1300rpm) 5 bar 5 bar 200 bar

LC420 72 cc/rev 135 bar 175 bar 98 l/min (1300rpm) 5 bar 5 bar 200 bar

LC580 108 cc/rev 140 bar 190 bar 136 l/min (1200rpm) 5 bar 5 bar 220 bar

• Fluid: mineral oil for hydraulic systems in compliance with ISO/DIN.

Temperature Optimum viscosity ale Max. viscosity allowed

-20 / +80 °C 12 – 100 cSt 750 cSt

• Filtration: class 19/16 contamination according to ISO 4406 to be

obtained with a ßx = 75 filter.

• Check circuit connections: they must be applied in the same

rotation direction as that indicated by the arrow on the pump front

flange.

Pic. 4.8

• Draining: connect directly to the tank above the maximum oil

level. Operating without draining line may damage the motor.

• Distributor: open-centre distributor in central idle position

(vacuum pump off). It must be equipped with an adjustable

overpressure safety valve.

• Motor pipeline: outlet pipe must not be of a smaller diameter than

that of the inlet port. Inlet pipes always have a diameter smaller than

outlet pipes. Choose preferably flexible pipes to avoid vibration

transmission.

• Tank: with suction pipe and return separated by baffles. If

necessary, use a heat exchanger to avoid oil heating above 70-80°C

and protect it from extreme pressure with a pressure relief valve.

Minimum approximate capacity: as twice as the circulation flow.

• Starting-up: be sure that the system is well cleaned and pour oil

into the tank and into the motor housing (necessary to lubricate the

internal bearings).

• Vent the circuit and adjust the overpressure safety valve to the

lowest possible value.

• Check the oil tank level.

• Increase pressure and rotation speed until operating values are

reached.

Pic. 4.9

1 Hdr pump 4 Oil filter

2 Distributor 5 * Heat exchanger

3 Hdr motor 6 * Safety valve

* optional components

KEEP AXELS PARALLEL

Loading...

Loading...