INSTALLATION

,

USE AND MAINTENANCE MANUAL

–

LC 300-420-580

REV

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

http://www.jurop.it

e-mail: info@jurop.it

6.1. Ordinary maintenance

• Installation and maintenance must be operated only by qualified personnel wearing the proper clothes and the necessary tools as well as

protection devices.

• Use suitable protection equipment (gloves, protection glasses, boots...)

• In the following table summarizes the main controls to be performed and the frequency of intervention.

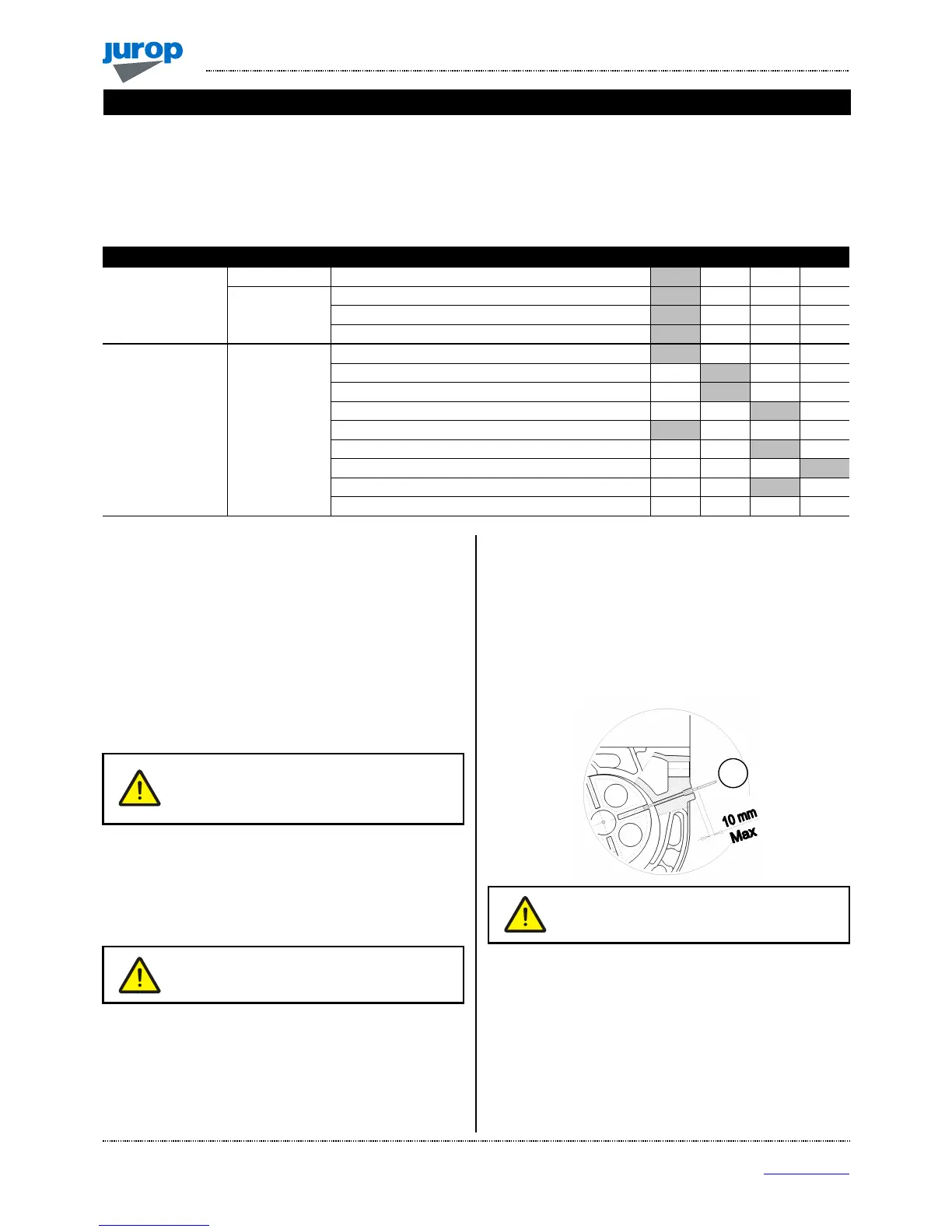

Operating condition Maintenance Area Check 8

H

50

H

500

H

1500H

OPERATING

Transmission Rotation speed

Pump

Lubrication: dripping into oilers

Operating pressure

Sound pressure level

STANDSTILL

Pump

Drain the oil gathered in the exhaust separator

Check vanes wear

Clean filter and vacuum line shutoff

Check pressure relief valve condition

Side mounted tank oil level

Gear box oil level

Gear box oil change (*)

Cooling system venting

Pump’s inner washing (**)

(*) The first oil change must be done inside 500 hours operation. Following

changes every 5000 hours or 12 months. In order to choose the most suitable oil, see

paragraph 2.5.

(**) After operation in dusty environments, after accidental sucking of liquids

inside the pump or before a long inoperativity period it is recommended to wash the

pump inside according to the procedure described at paragraph 5.2.

Checking the drip oilers

• Check dripping into the oilers.

• Be sure it is regular (about 40 drops/min at max. speed, with

degree of vacuum > 50%) to grant a correct lubrication of the pump. At

lower speeds, the number of drops must be directly proportional.

If the pump is run without lubrication, the internal

components may quickly damaged due to

overheating. Stop the vacuum pump and check

the oil level and the lubricating pump.

Checking the side mounted oil tank level

• Do not run the pump with oil level under the minimum level: that

may lead to dry functioning and cause serious damages.

• Tank capacity: 4l.

• Use pure fresh oil.

Do not re-use the exhausted oil gathered on the

bottom of the exhaust silencer.

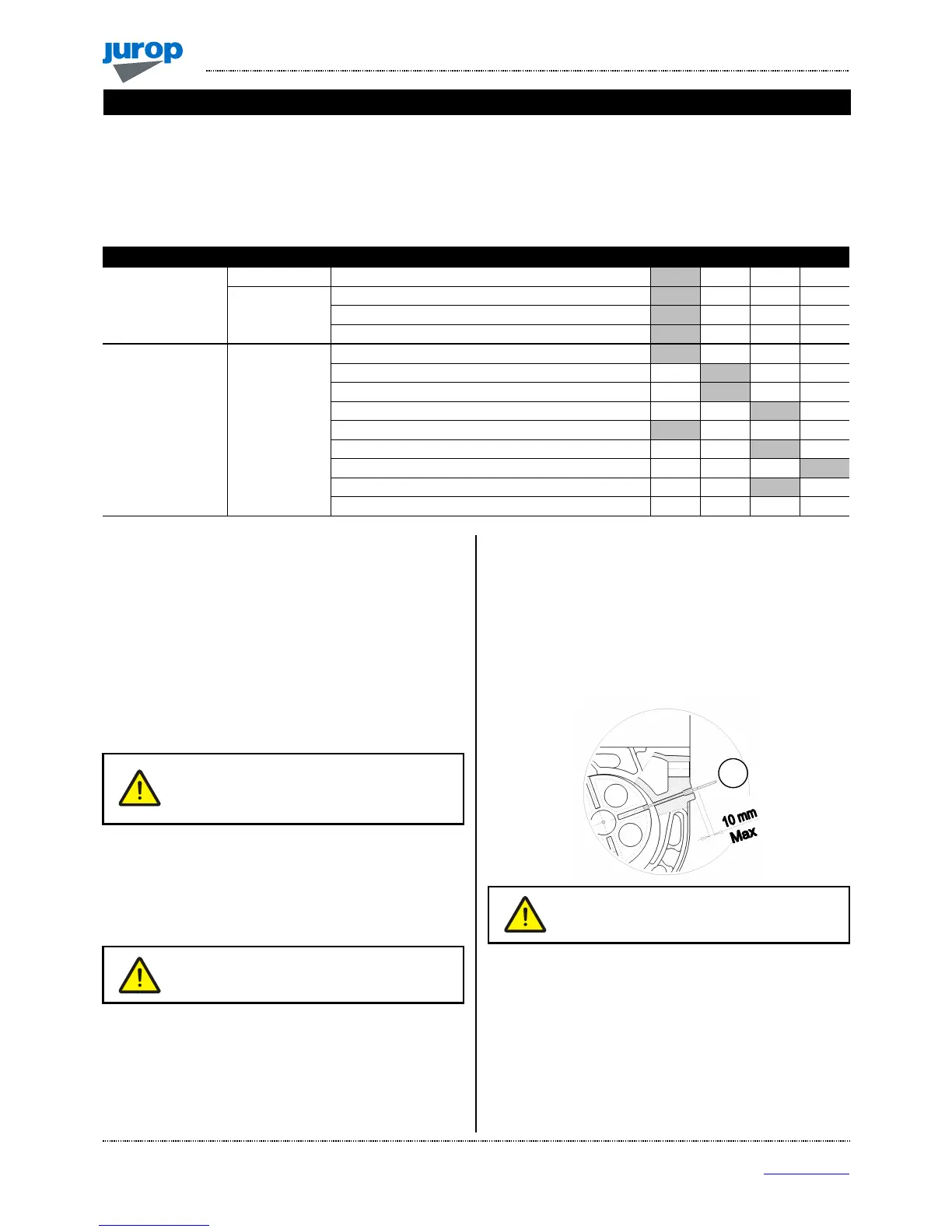

Checking the vanes wear LC300 - LC420

• Unscrew the vanes wear check-plug on the housing (pos. CL).

• Turn the shaft until you see the vane.

• The vanes should slide to the bottom of the seat due to gravity:

check they really do.

• Insert a rod of 6 mm Ø with its conic end towards the pump (rod

supplied with pump).

• Turn the shift manually and touch the outside diameter of the rotor

with the checking rod, mark it a first time. Keep turning the shift till the

rod falls inside a vane groove. Mark it again and measure the gap

between the two marks.

• If this gap exceeds 10 mm, then the vanes must be replaced.

• At the end of this procedure, do not forget to replace the plug.

• Replace all vanes at the same time.

Pic. 6.1

Replace the vanes when their wear exceeds 10

m\m (L – L min): they may break. Replace all

vanes at the same time.

Checking the vanes wear LC580

• Unscrew the vanes wear check-plug on the front flange (pos. CL).

• Turn the shaft until you see the vane.

• The vanes should slide to the bottom of the seat due to gravity:

check they really do.

• Replace the vanes when their wear exceeds 10 m\m (L – L min):

they may break.

• At the end of this procedure, do not forget to replace the plug.

• Replace all vanes at the same time.

Loading...

Loading...