Operation and Maintenance

4

Operating Principle

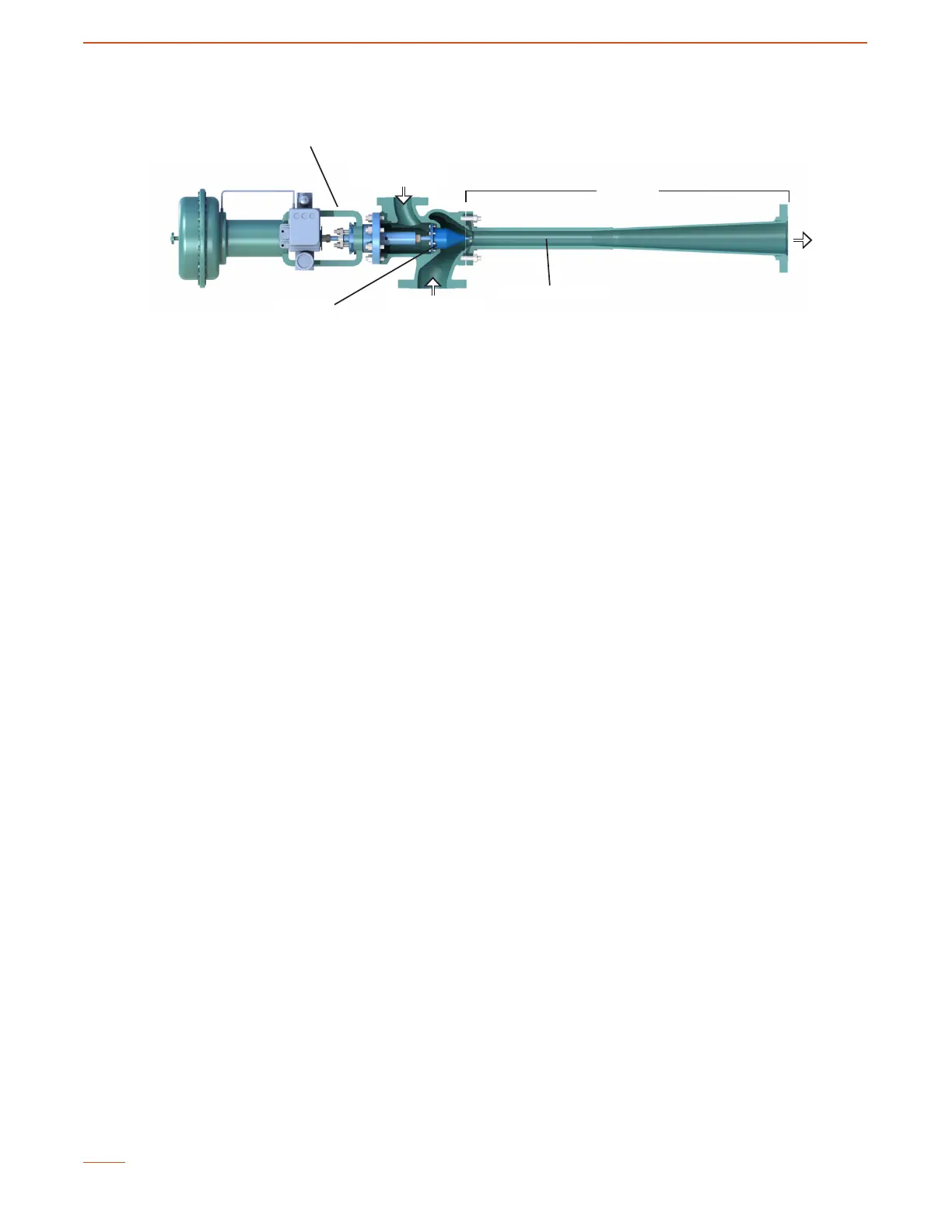

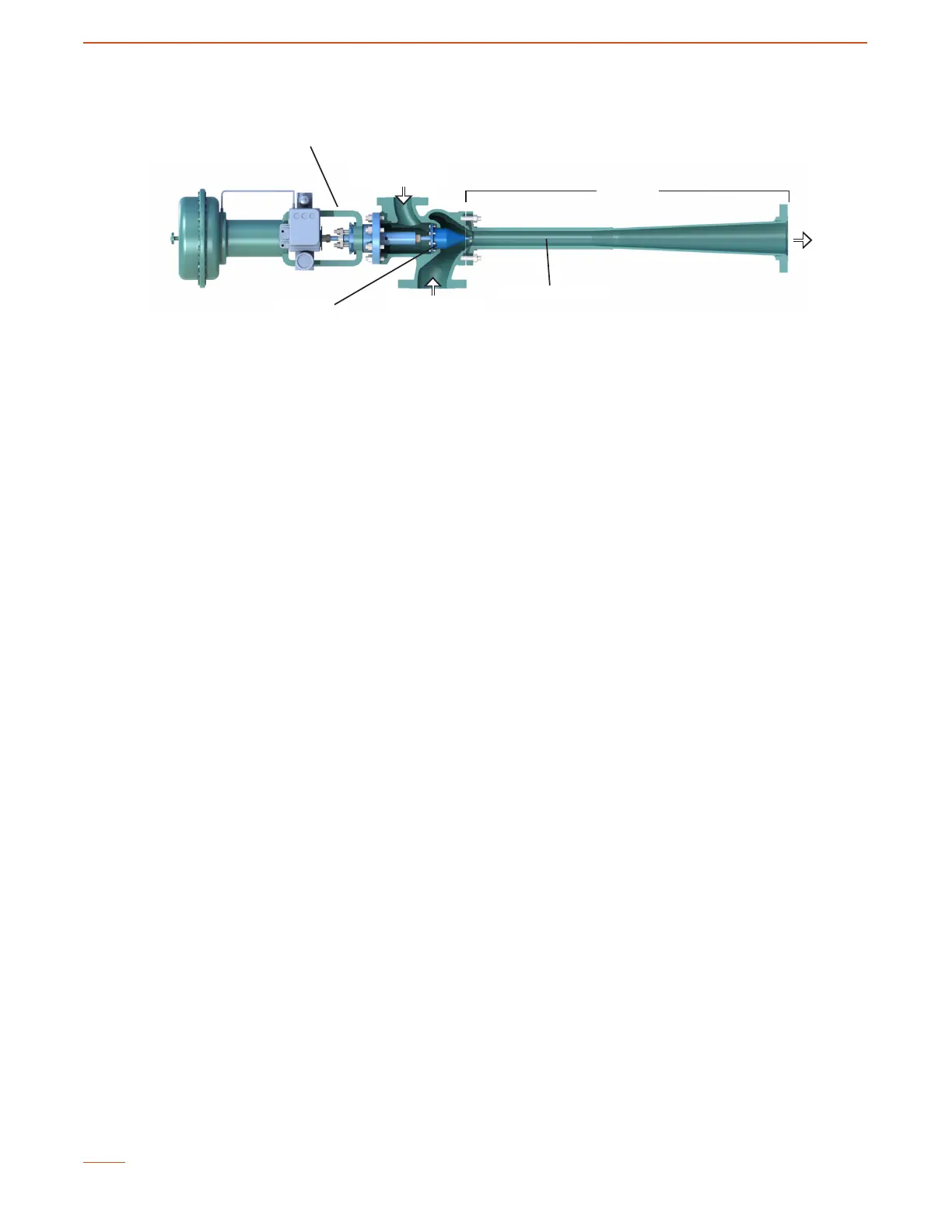

High pressure motive steam enters the thermocompressor via the motive steam nozzle where it is expanded from the inlet pressure

to that of the design low pressure, or suction value. As the motive steam passes through the nozzle, the pressure energy falls, and the

velocity is attained in the nozzle throat.

The stream of high velocity steam leaves the nozzle and passes through the body to enter the convergent section of the diffuser,

where it is brought into contact with the low-pressure stream. Entrainment will occur as the motive jet transfers energy to the low-

pressure stream by shear.

The flow progresses through the diffuser throat and the two streams mix, resulting in uniform cross-sectional velocity. As the flows

mix, the pressure rises. In the divergent section of the diffuser, area increases, velocity decreases, and pressure rises to the required

discharge pressure.

With the exception of the actuator and modulating spindle, thermocompressors have no moving parts. Operation and maintenance

problems should, therefore, be negligible. On the assumption that the thermocompressor has been specified correctly, satisfactory

operation of the equipment will depend upon:

1. Correct installation

2. Correct utilities

3. Periodic inspection of the installation

A thermocompressor can be installed in any convenient location but it is recommended that its orientation be in the vertical plane.

This will smooth the operation of the actuator assembly and minimize piston wear in the plug guide.

Once the location for the thermocompressor has been determined, due consideration should be given to the motive connection, the

suction connection, and the discharge connection.

The motive connection:

It is a short-sighted policy to install too small of a main steam supply, therefore it is recommended that the maximum demand flow be

considered when sizing the steam supply main.

Dry steam is a basic requirement for good performance and easy maintenance. The motive steam nozzle is designed for 98%

or better quality steam to give efficient performance. Wet steam is detrimental both to the performance and to the parts of

a thermocompressor. It erodes the nozzle and could affect the performance by clogging the nozzle with water droplets. It is

recommended, therefore, that all steam supply lines should come off the top of the main steam supply line and, where necessary,

provision be made for draining. A well designed steam separator and trap assembly will correct a wet steam condition.

Nozzle

Actuator

Mixing section

Discharge

Low pressure

steam

High pressure

steam

Diffuser

Loading...

Loading...