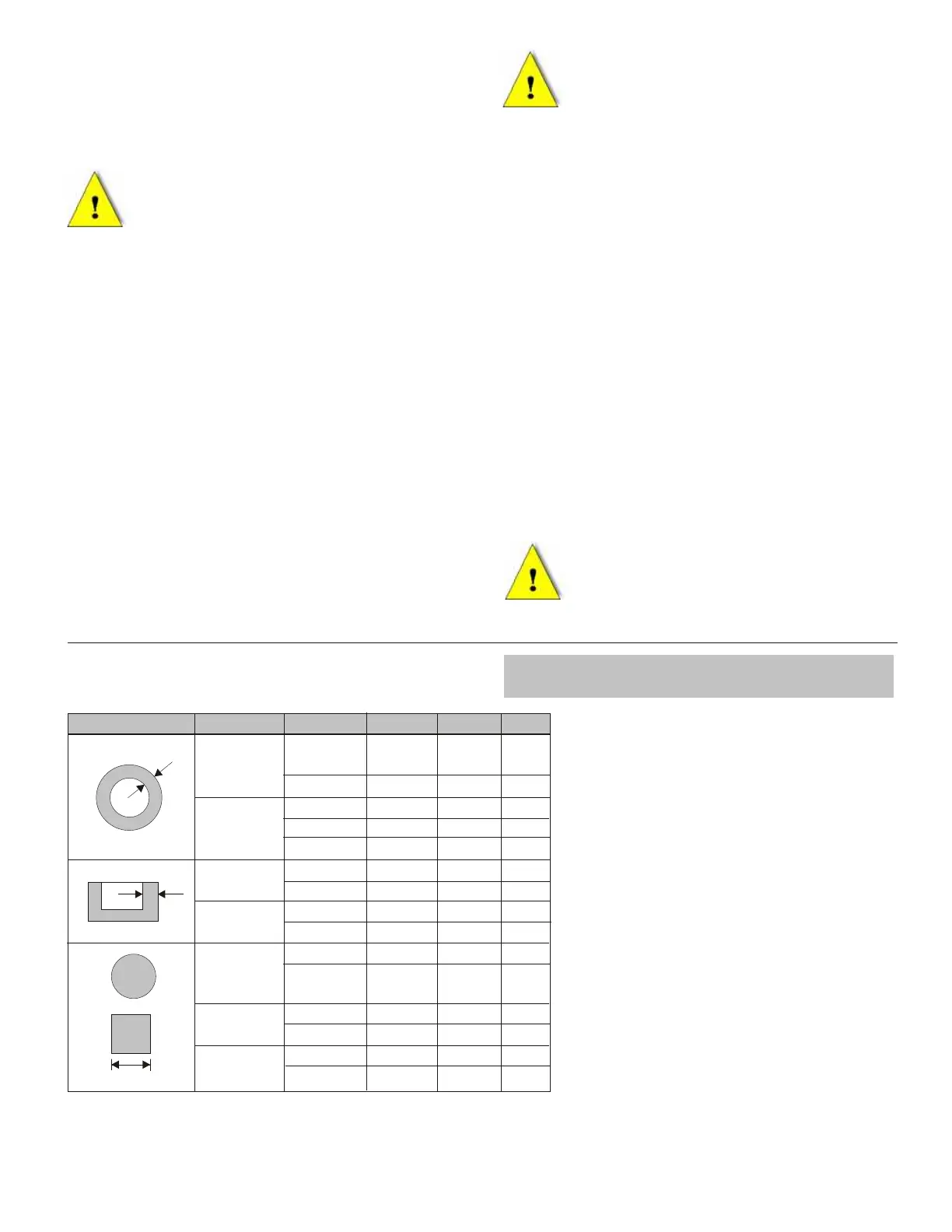

Sec. Mat. S Z V R

All 3/16-3/4 6 - 10 210

Ot 58 210

Br 14 < 3/16 14 210 ü

Fe 35 < 3/16 14 210 ü

Fe52 6 - 10 210 ü

> 3/4 4 - 6 210

All < 3/16 14 210

> 3/16 6 - 10 210 ü

Fe 37 < 3/16 210 ü

> 3/16 6 - 10 105

All < 2” 6 - 10 210

Ot 58 > 2” 4 - 6 210

Br 14

Fe 37 < 2” 6 - 10 105 ü

C 40 > 2” 4 - 6 105 ü

Acc. Inox < 2” 6 - 10 105 ü

> 2” 4 - 6 105 ü

Table 3 (refer to Section 4.5)

" Re-screw the plug;

" Pour the “virgin” liquid into the tank until it

reaches the top. (2 - fig. 4);

" Reposition the cover/filter (3).

Contact a specialized and authorized

company to dispose of the old oils. Do

not throw the cooling liquid in the

environment.

8.3 Extraordinary Maintenance

Includes the operation by skilled personnel for

repairs or replacements of worn, faulty parts etc.

8.4 Replacing the Blade

" Loosen the lever (10 - fig. 1) and move (all along

its stroke) the blade guide unit downwards.

" Remove the screws (1 - fig. 5).

" Lift the rear guard (1 - fig. 6) of the operating

head and make sure that it is in stable conditions

and cannot fall accidentally.

The blade tension lever (6 - fig. 1)

requires considerable effort to loosen.

The easiest way is to lower the cutting

head to the lowest position and use

natural leverage to move the lever.

" Remove the blade (2 - fig. 6) from the driven

pulley (3) then from blade guide devices (4 - fig.

6) and finally, from the driving pulley (5).

" Insert a new blade following the reverse order of

what has just been described.

" Check that the new blade is correctly inserted,

then pull the tension lever (6 - fig. 1)

energetically outwards.

" Close the guard (1 - fig. 6) and fasten it with the

two screws (1 - fig. 5).

" Start the machine and start without load, at short

impulses, the blade will self-center on the

pulleys.

" Check that the blade tension is at its maximum,

pulling the lever again (6 - fig. 1).

With the new blade, make the first 4-6

cuts with a gentle cutting pressure in

order to “break-in” the new blade.

Doing this will increase your blade life.

Sec. = Section of the piece to be cut

Mat. = Material of the piece to be cut

S = Thickness of the piece to be

cut (in inches)

< = Lower than the stated value

> = Higher than the stated value

Z” = Number of teeth per inch of

the blade

V = Cutting speed (ft/min.) feet

per minute

R = Cut with cooling liquid (ü)

Loading...

Loading...