STOPPING THE ENGINE

9

TO STOP THE ENGINE, PROCEED AS FOLLOWS:TO STOP THE ENGINE, PROCEED AS FOLLOWS:

Do not connect or disconnect parallel cables while the generator

is running. If you plan to use only one generator, the parallel

cables must be disconnected with the engine off.

ATTENTION - DANGER!

DISCONNECT ALL DEVICES BEFORE STOPPING THE GENERATOR!DISCONNECT ALL DEVICES BEFORE STOPPING THE GENERATOR!

Do not stop the generator with the devices turned on. This may disable the generator or devices connected to it!

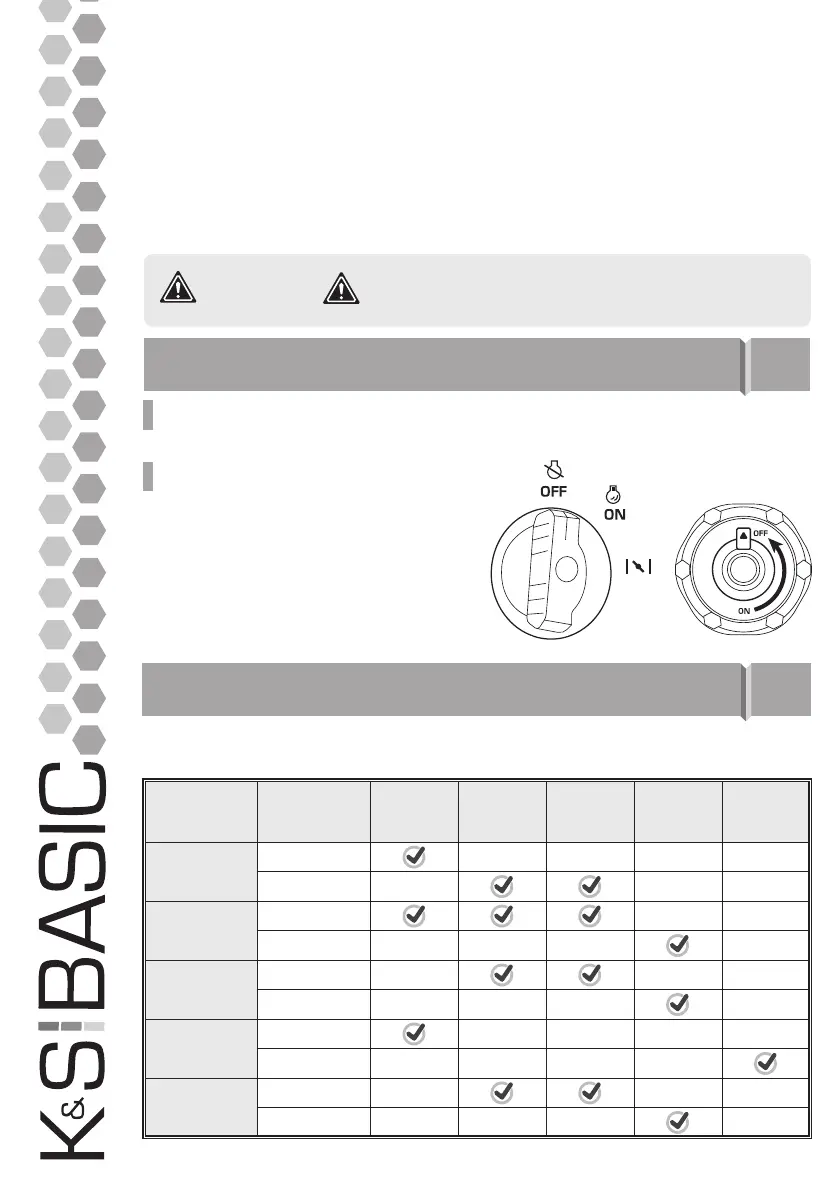

Fig. 3 Fig. 4

1. Turn off all devices.

2. Allow the generator to run idle for approx. 1-2 minutes.

3. Set the engine switch to the “OFF” position.

4. Set the 3-in-1 switch to “OFF” (Fig. 3).

5. Allow the generator to cool down.

6. Unplug the devices.

7. After the generator stops, allow it to cool down and

close the vent (for model KSB 21i S set to OFF, as shown in Fig. 4).

TECHNICAL MAINTENANCE WORKS

10

This manual compliance! You can find a list of service center addresses on the website of exclusive importer:

www.konner-sohnen.com

generators ensures total rated output power of these generators. When the generators are connected in parallel, the

power loss is 0.2 kW of the total rated power that can be obtained.

During parallel operation, the ECONOMY MODE switch must be in the same position on both generators.

1. Connect the KSB PC-1 parallel cable to the dedicated outputs on the generator control panel. Do not use any other

cables, don’t combine different generator models.

2. Start the engines of the same generator models (KSB 21i S), check that the green WORKING MODE indicator on

each generator is on.

3. Plug the appliance into a socket.

4. Switch on the appliance.

If the overload indicator lights up, follow the standard generator overload procedure described in section 5 (reduce

the load and press the RESET button on both generators).

TECHNICAL MAINTENANCE WORKS

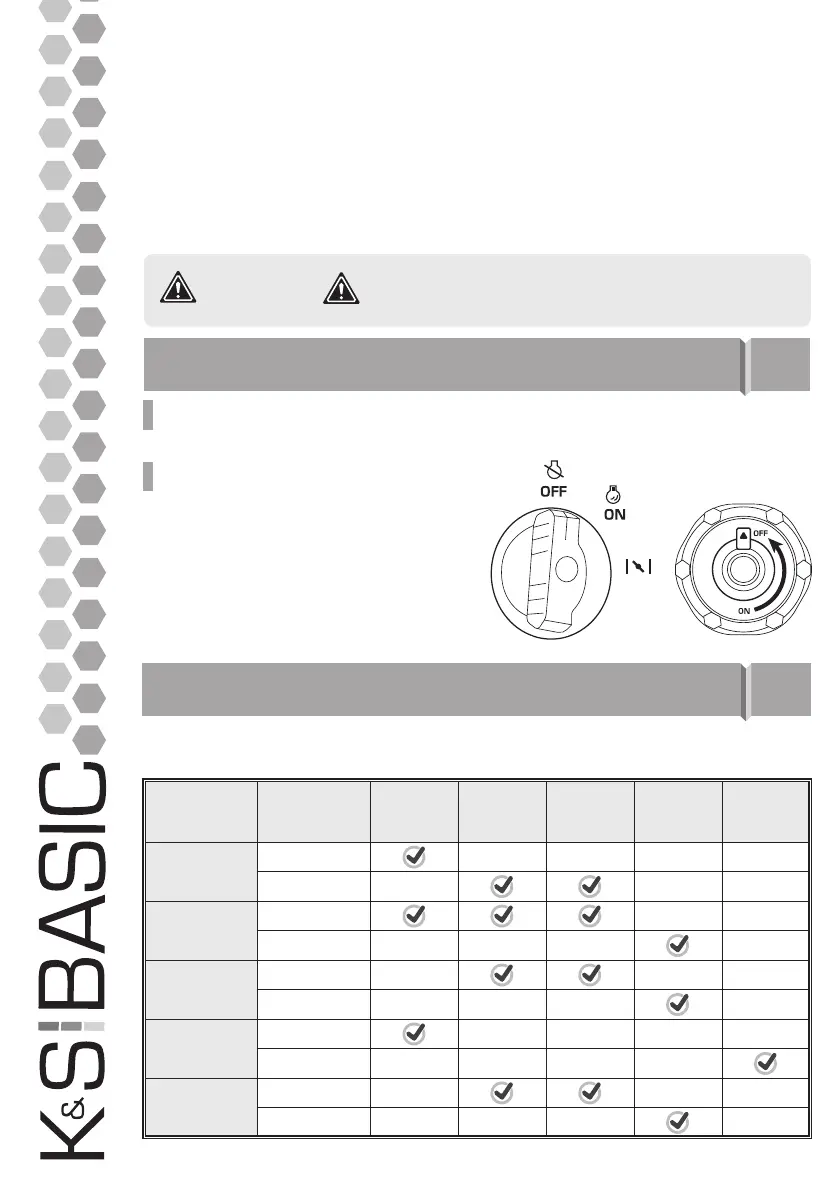

Unit

Action

At each

start

First

month

or 20

operating

hours

Every 3

months

or 50

operating

hours

Every 6

months

or 100

operating

hours

Every year

or 300

operating

hours

Motor oil

Level check

Replacement

Air lter

Check /Cleaning

Replacement

Spark plug

Cleaning

Replacement

Fuel tank

Level check

Cleaning

Fuel lter

Check (clean out)

Replacement

konner-sohnen.com | 10

Loading...

Loading...