operation (230 Volt AC line input with 90

Volt DC SCR rated motor or 130 Volt DC

PWM rated motor) set jumper J1 to

“90V” position. However, in step-down

operation the motor may have reduced

brush life - consult motor manufacturer.

Note: Do not connect motor armature

leads to F1 and F2 terminals. Do not

use F1 and F2 terminals for PM motors.

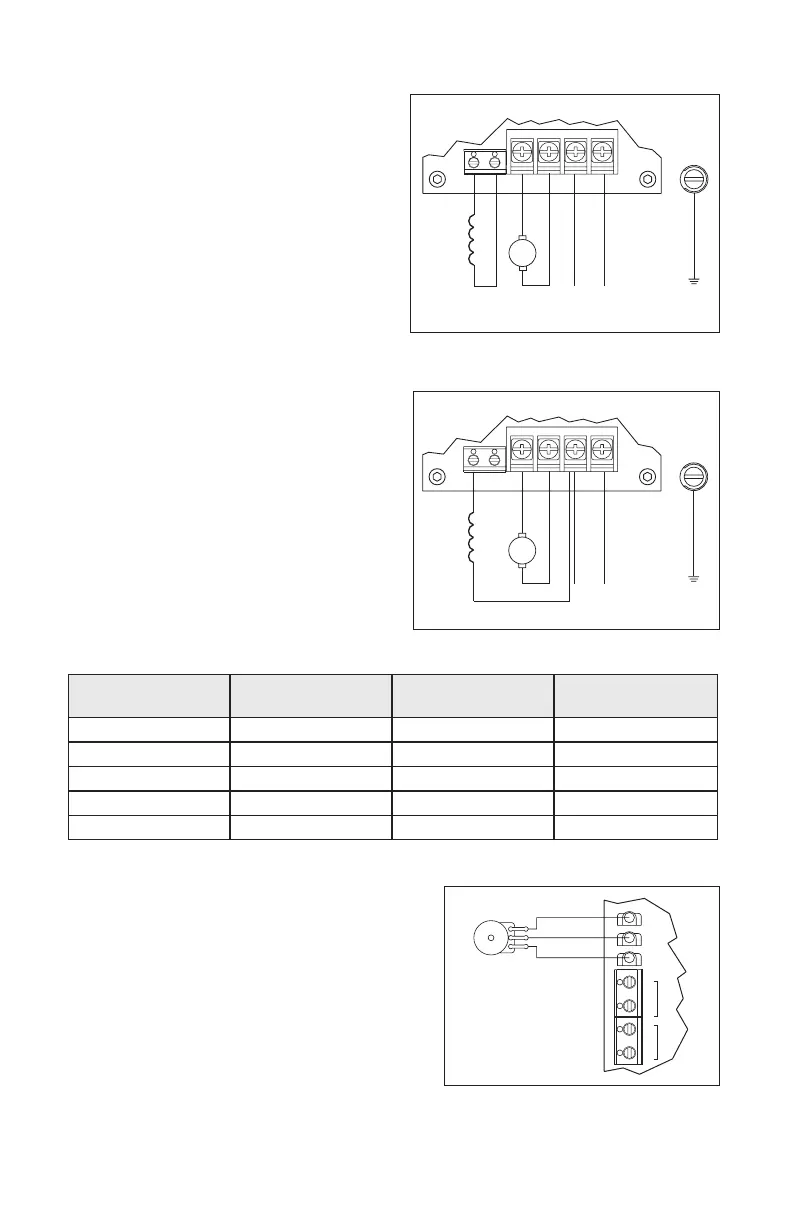

D. Full Voltage Field Connection (Shunt

Wound Motors Only) – Wire the motor

field leads to F1 (+) and F2 (-) terminals

of TB2 as shown in Figure 4 and Table 4.

Note: Do not connect motor armature leads to F1 and F2 terminals.

Warning! Do not use F1 and F2 termi-

nals of TB2 for any purpose other than

to power the field of a shunt wound

motor.

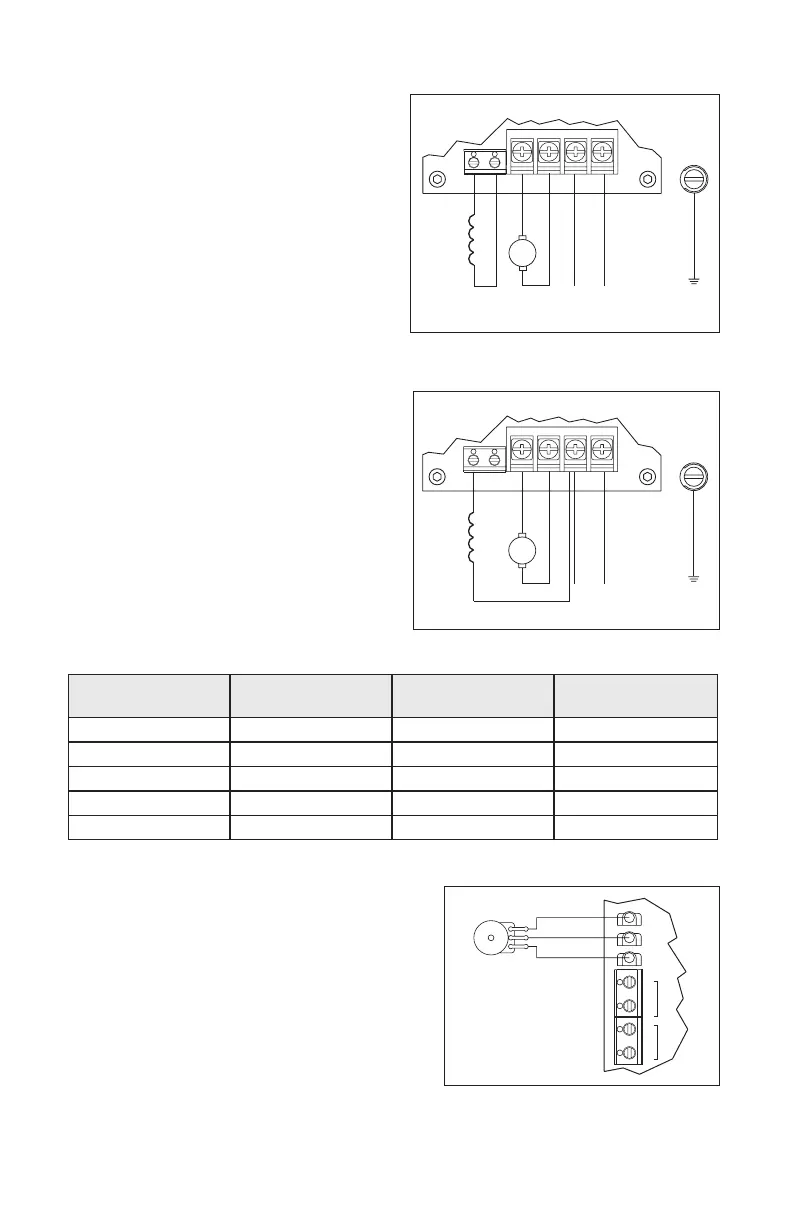

E. Half Voltage Field Connection (Shunt

Wound Motors Only) –

Wire the motor

field leads to F1 (+) and L1 (-) terminals

of TB2, as shown in Figure 5 and Table 4.

Note: Do not connect motor armature

leads to F1 and F2 terminals.

Warning! Do not use F1 and F2 termi-

nals of TB2 for any purpose other than

to power the field of a shunt wound

motor.

F. Remote Main Speed Potentiometer

Connection –

The control is supplied with a

prewired main speed potentiometer mounted

on the front cover. To operate the control from

a remote potentiometer (5kΩ), remove the

white, orange, and violet potentiometer leads

from P1, P2, and P3 terminals, respectively.

The leads may be taped and left inside the

control. The potentiometer assembly may be

removed if a watertight seal is used to cover

the hole in the front cover. Connect the

remote main speed potentiometer wires to

terminals P1 (low side), P2 (wiper), and P3

(high side) as shown in Figure 6.

7

Loading...

Loading...