14

SNA-Series Tankless Heater Installation

10/17/2014 Keltech • 215-1815 Rev. B; ECN 130011

Special Installation and Operating Instructions

Tankless Water Heaters With Optional Class I Division 2 Purge EXP2 Option and

EXP2LC and EXP2LCPM

General Information

All Keltech Tankless Water Heaters with a model number suffix of – EXP2 and EXP2LC have been fitted with a Z

purge system to pressurize the enclosure suitable for use in Class I Division 2 Hazardous Locations.

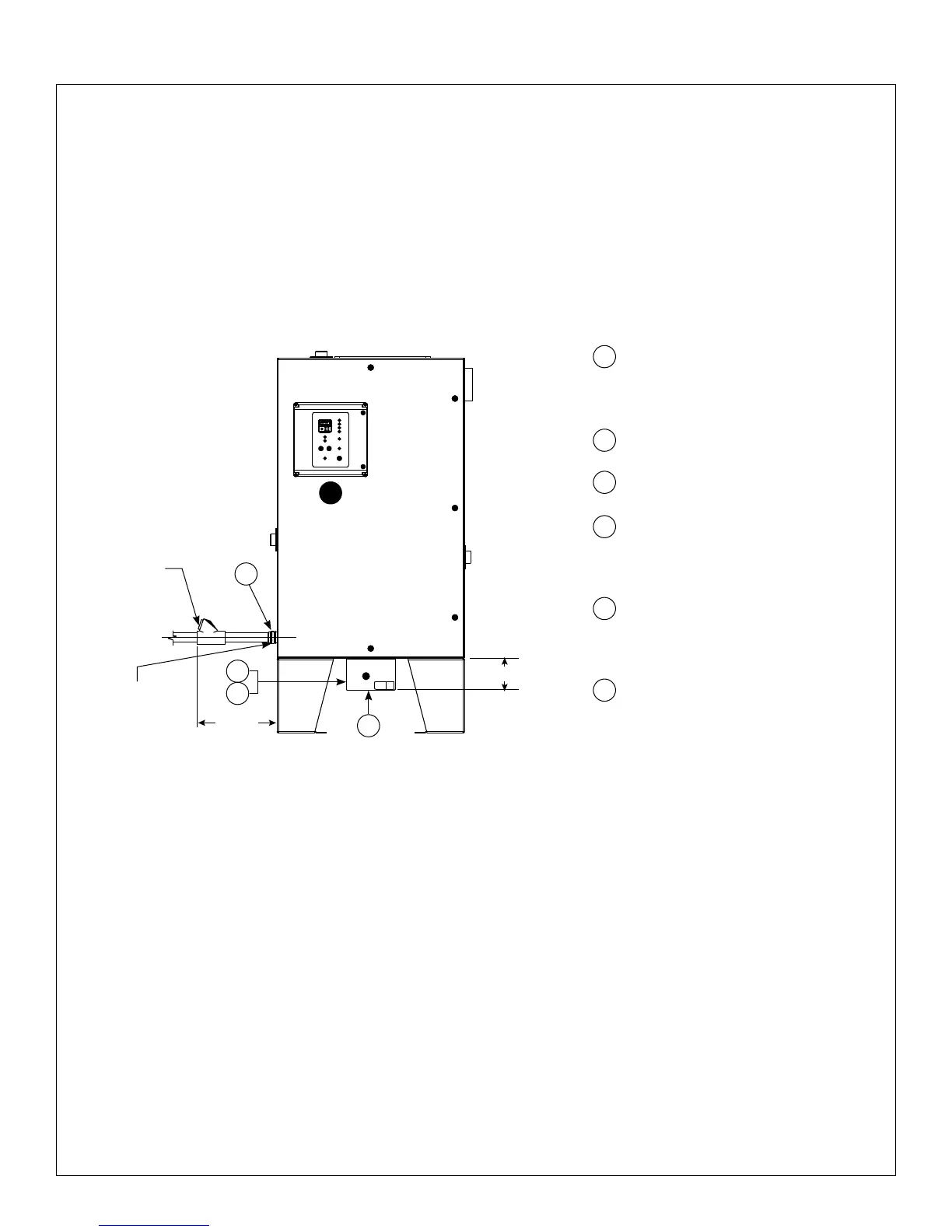

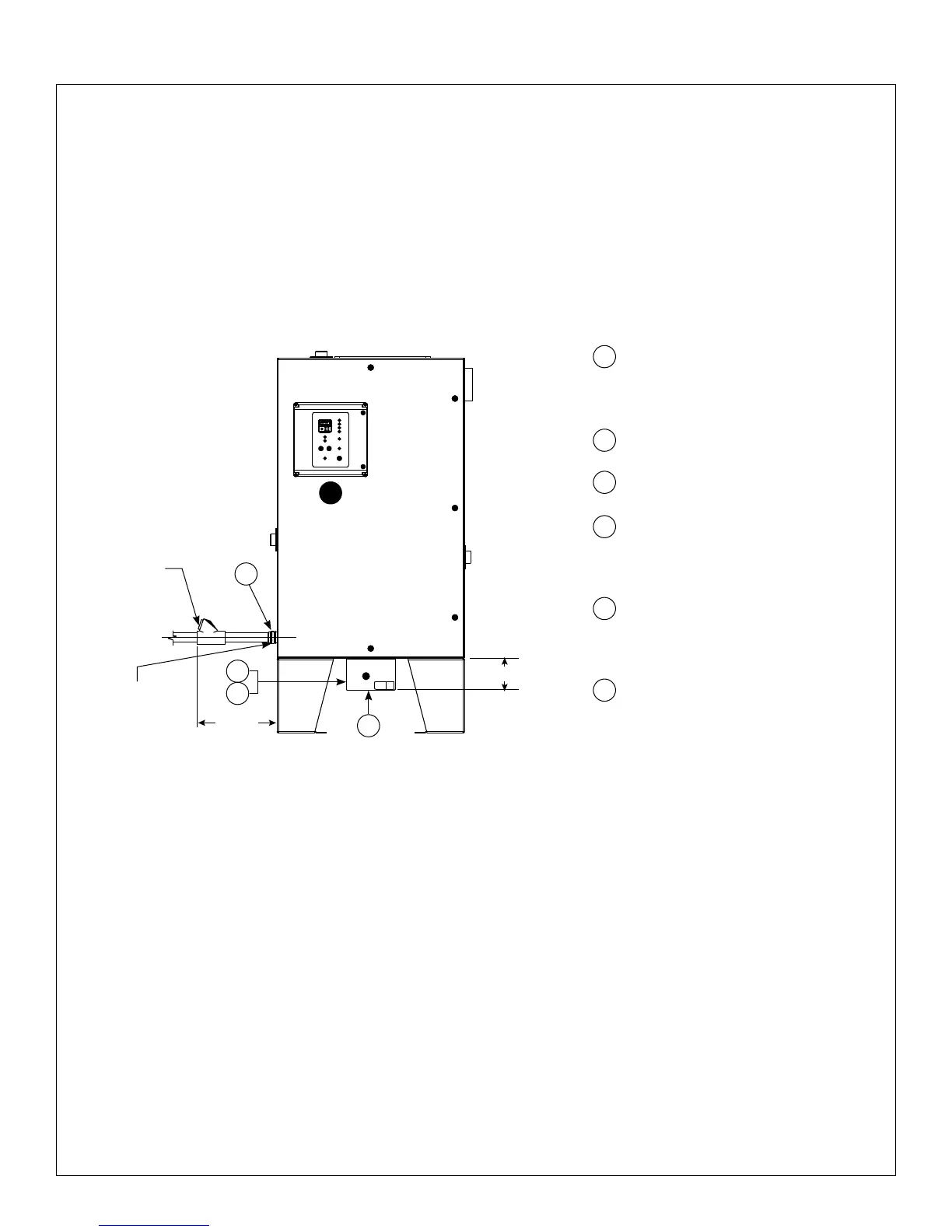

A Continuous Flow (Model CF) or Leakage Compensation (Model LC) Mini-Z Pressurizing System has been fitted to

the bottom of the enclosure (See Figure 6).

Outlet

18"

(458mm)

Max

Explosion proof

sealing fitting

supplied by others

Purge System

Relief Valve

Conduit Hub

Class 1 Div. 2

supplied by others

Inlet

5" (127mm)

1

1

2

3

4

5

6

3

5

6

Suggested region for power

entrance at left/bottom of enclosure.

Entrance hole and components to

be provided by installer.

All plumbing fittings are 1-1/4" NPT

female threaded.

Purge Control Panel

Class 1 Division 2

All installation egress from

panel must be sealed (electrical

conduit) for proper explosion proof

installation.

Spark arrestor with calibration orfice

is located behind the purge control

unit and through the bottom of the

enclosure.

Purge gas/compressed air inlet

fitting here.

FIGURE 6

EXP2 & EXP2LC Installation Notes

1. Any tubing, conduit or fittings connected to the Pressurized Enclosure (PE) must conform to local codes for

flammability ratings.

2. All egress into PE must be plugged and properly sealed to minimize leakage of purge air. Use hazardous

location sealing fittings suitable for Class I locations within 18" of enclosure (See Figure 6).

3. There are two types of purge systems:

EXP2 option is a continuous flow purge system and is calibrated to flow at .9 SCFM. To minimize waste, plug

and seal all openings and conduit.

EXP2LC is a leakage compensation purge intended to have minimal flow after the initial purge time. The PE is

built as leak tight as possible and the LC system merely tops up for any enclosure leakage.

4. The system is designed for use primarily with compressed air. The source of the compressed air must be

from a non-classified area. Purge air must be clean, dry and free of flammable gases. When inert compressed

gasses are used (Nitrogen, for example) the installer and facility manager must take suitable precautions

on-site so that buildup of the inert gas does not present a health hazard. Where risk of asphyxiation exists, a

warning label must be fitted to the Pressurized Enclosure (PE).

5. Adjustment of Purge System is not necessary. System is fully calibrated.

6. Connect to Purge System where indicated in Figure 6. Connection port is 1/4" NPT female. Supply pressure

must be regulated to 60–115 PSI.

Loading...

Loading...