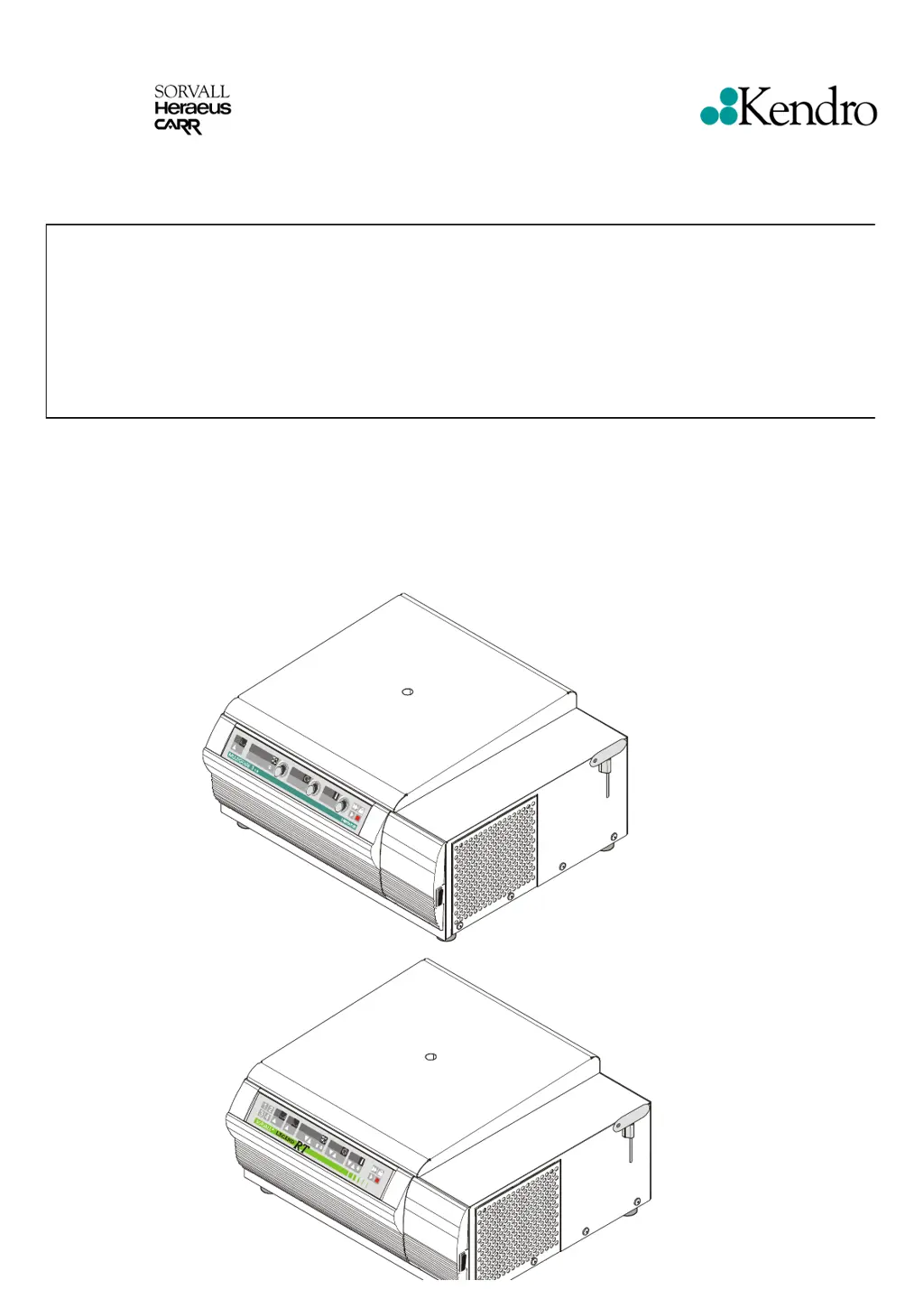

What to do if 'bAL' message appears in speed display of Kendro Multifuge 3 S-R Laboratory Equipment?

- WwoodwardpaulaAug 16, 2025

If the 'bAL' message appears on the speed display, it indicates an imbalance. Here's what you should do: * Open the lid and check the rotor loading. * Ensure the base is sturdy and not causing vibrations; reinforce or change it if necessary. * Verify the centrifuge drive is correctly leveled using the unit’s feet. If the rotor itself has an imbalance, discontinue use and return it to Kendro. Damaged drive shafts or rotor fixings may require replacing the collet chuck or motor. Also, consider replacing the sensor board or the main board.