Installation and Maintenance

June 2020 2-4 P/N 06-237620-001

2-6 MAINTENANCE PROCEDURES

A program of systematic maintenance is essential for continuous, proper operation of all Natura

IGS Systems. Follow a periodic maintenance schedule as outlined in Table 2-1. Additionally,

have an Authorized Natura IGS Systems Distributor perform preventative maintenance as

outlined in Table 2-2.

If areas of rust or corrosion are found during the inspection of cylinders contact your

Authorized Natura IGS Systems Distributor for further examination.

2-6.1 Preventative Maintenance Schedule

As an owner, perform preventative maintenance per Table 2-1.

WARNING

Natura IGS cylinders and components must be handled, installed, inspected

and serviced only by qualified and trained personnel in accordance with the

instructions contained in this manual and Compressed Gas Association (CGA)

pamphlets C-1, C-6 and P-1. CGA pamphlets my be obtained from the

Compressed Gas Association website: http://www.cganet.com.

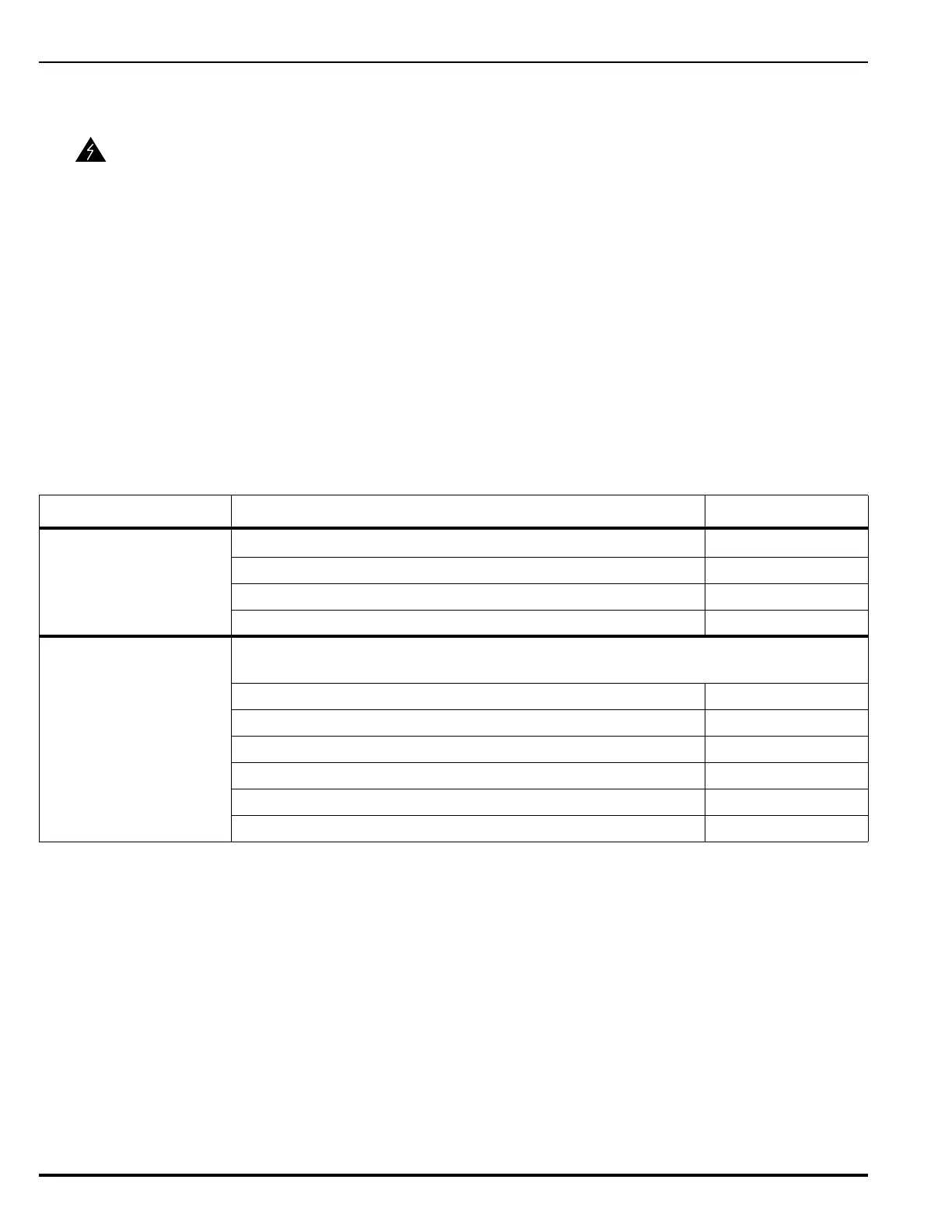

Table 2-1. Owner Preventive Maintenance Schedule

Schedule Requirement Paragraph

Weekly

Inspect Natura IGS cylinder and check the cylinder pressures

Section 2-7.1

Check nitrogen pilot cylinder pressures Section 2-7.2

Perform hazard and enclosure inspection Section 2-7.3

Perform pipework and controls inspection Section 2-7.4

Monthly

Perform Weekly Inspection as outlined in Section 2-7

and the following additional tasks:

Perform General Inspection Section 2-8.1

Inspect Hazard Access Section 2-8.2

Inspect Hoses Section 2-8.3

Inspect Release Units and Slave Gauges Section 2-8.4

Inspect Cylinder and Valve Assembly Section 2-8.5

Inspect Electric Control Heads Section 2-8.6

Loading...

Loading...