USSC 1716 USSC

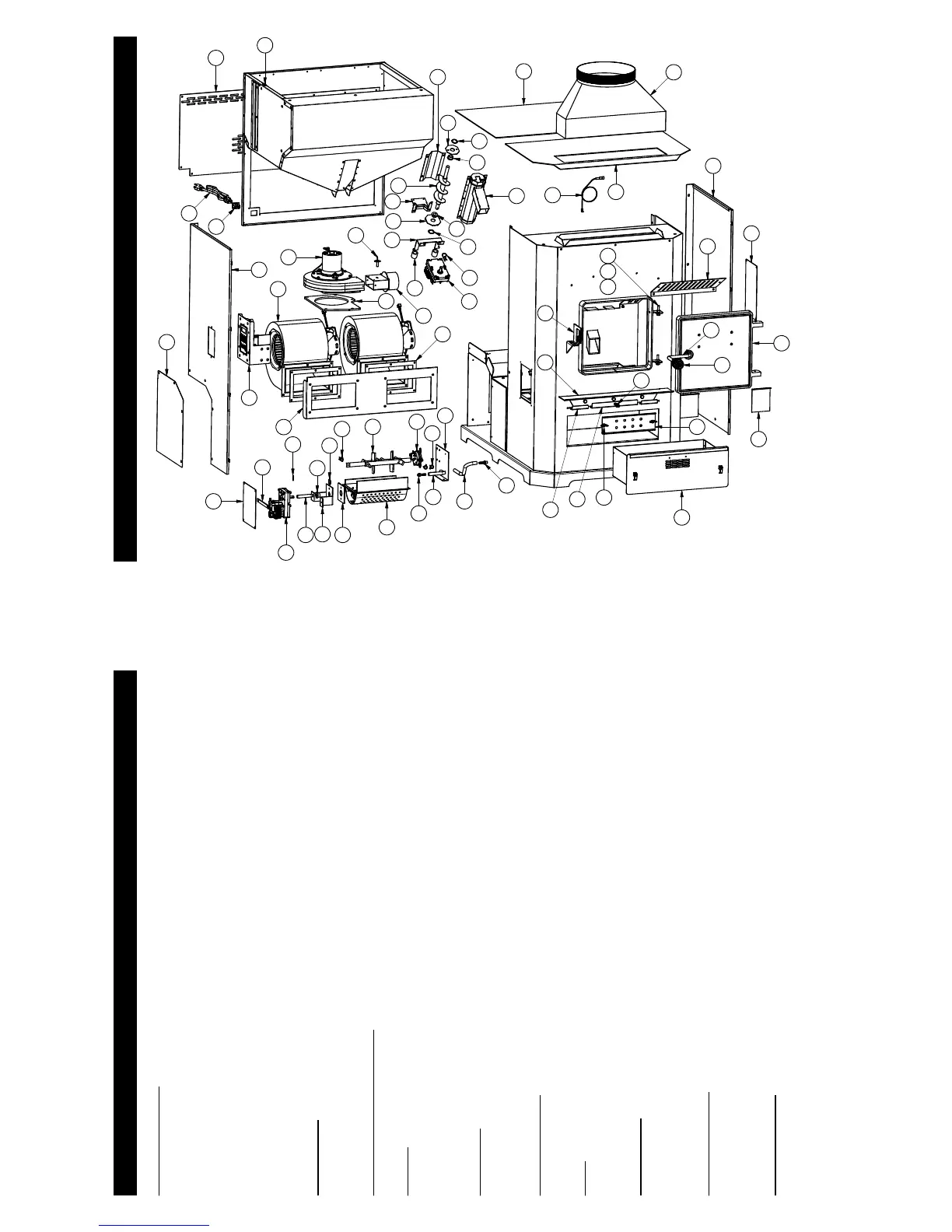

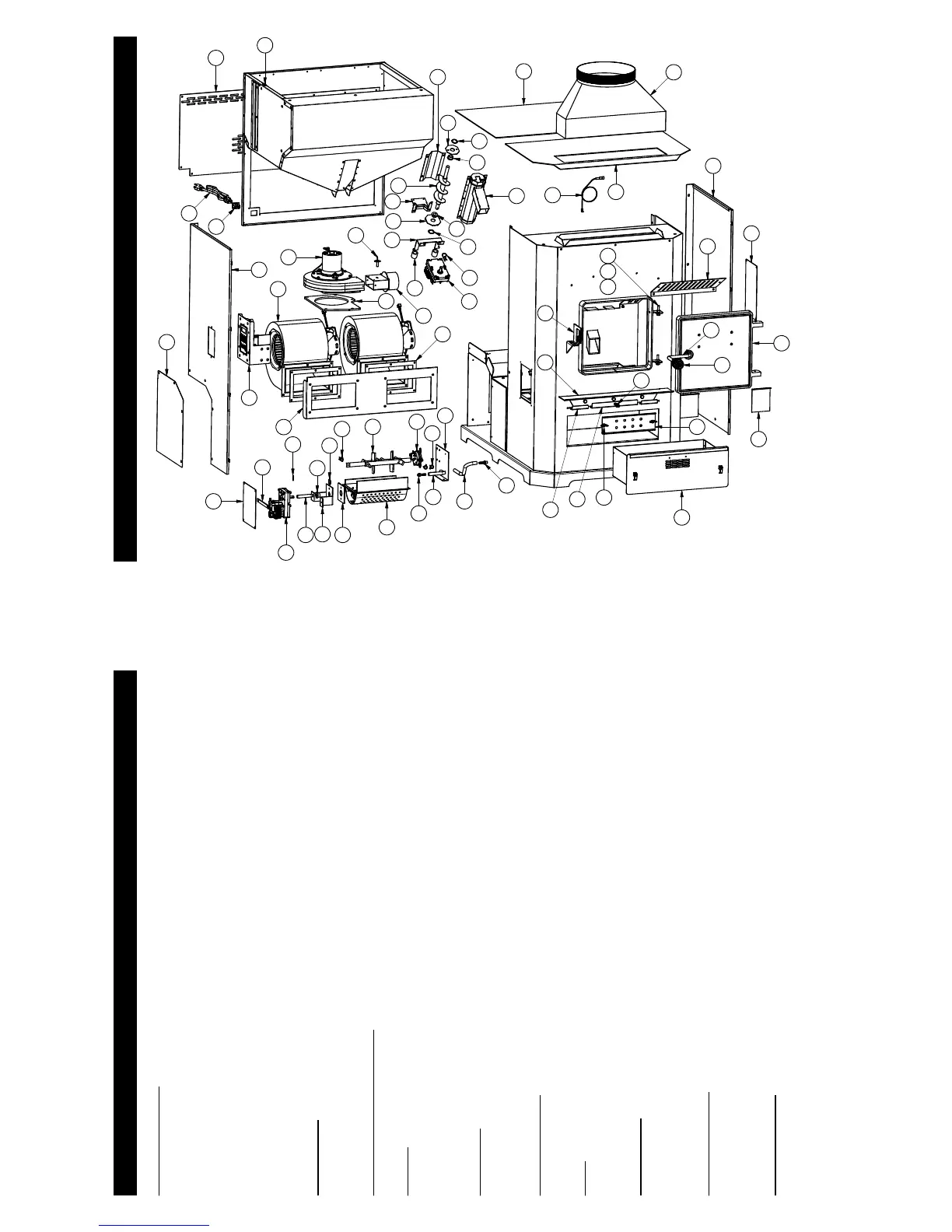

Parts Diagram

INTERIOR CHAMBERS

Open the Ash Cleanouts and scrap all ash into the ash pan. Open the damper and allow the ashes to fall into the ash pan. The

damper may need to be slid in and out several times to clear any ash build-up. This may need to be done daily depending on fuel

consumption. Be sure the ash cleanouts located on either side of the damper are completely closed before operating.

Periodically remove and clean the burnpot and the area inside the burnpot housing. In particular it is advisable to clean out the holes

in the burnpot to remove any build up that may prevent air from moving through the burn pot freely.

Placing the Burnpot and the Agitator in a bucket of water and allowing it to soak will help with the removal of clinker build-up.

Remove the two cleanout slides on each side of the burnpot at the rear of the burn chamber to clean out all ash.

Remove the exhaust clean out plate located behind the ash pan and clean the exhaust duct of all ash.

If a vacuum is used to clean your furnace, we suggest using a vacuum designed for ash removal. Some regular vacuum cleaner (i.e.

shop vacs) may leak ash into the room.

ASH DISPOSAL

or otherwise locally dispersed, they should be retained in the closed container until all cinders have been thoroughly cooled.

Check the hopper periodically to determine if there is any fuel or fuel matter that is sticking to the hopper surface. Clean as needed.

Inspect the main door and glass window gaskets periodically. The main door may need to be removed to have frayed, broken, or

King” Dealer.

Also, be careful not to damage the gaskets on the backside of the cleanouts on the front of the unit. If gaskets become torn or

damaged, they must be replaced.

FAN MOTORS

Clean the air holes on the motors of both the draft fan and room air fans annually. Remove the draft fan from the exhaust duct and clean

out the internal fan blades as part of your fall start-up. A new gasket may be purchased from United States Stove’s Parts Department.

PAINTED SURFACES

Painted surfaces may be wiped down with a damp cloth. If scratches appear, or you wish to renew your paint, contact your Authorized

KING” Dealer to obtain a can of suitable high-temperature paint.

GLASS

We recommend using a high quality glass cleaner. Should a build up of creosote or carbon accumulate, you may wish to use 000

steel wool and water to clean the glass. In the event you need to replace the glass, only high temperature ceramic glass of the correct

King” Dealer to obtain this glass.

FALL START UP

intake pipe. Turn all of the controls on and make sure that they are working properly. This is also a good time to give the entire

furnace a good cleaning throughout.

SPRING SHUTDOWN

After the last burn in the spring, remove any remaining fuel from the hopper and the auger feed system. Scoop out the fuel and then

“ON” button with the viewing door

hopper with an aerosol silicone spray if your furnace is in a high humidity area. The exhaust system should be thoroughly cleaned.

YEARLY SERVICING

CAUTION! CLEANOUT OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY, AND DRAFT FAN IS ESPECIALLY IMPORTANT

AT THE END OF EACH HEATING SEASON TO MINIMIZE CORROSION DURING THE SUMMER MONTHS. A yearly inspection,

King

Maintenance

1

2

3

4

5

6

7

8

9

10

11

12

13

16

19

20

21

22 23

24

25

26

26

27

28

29

30

18

31

29

32

33

34

35

36

37

16

17

38

39

40

48

41

49

50

51

28

29

52

53

54

50

28

56

57

58

59

60

61

62

63

64

65

47

42

44

45

46

43

Loading...

Loading...