GL0014K Owners Handbook BioDisc BD, BE, BF, BG, ND, NE, NF, NG

Page 15

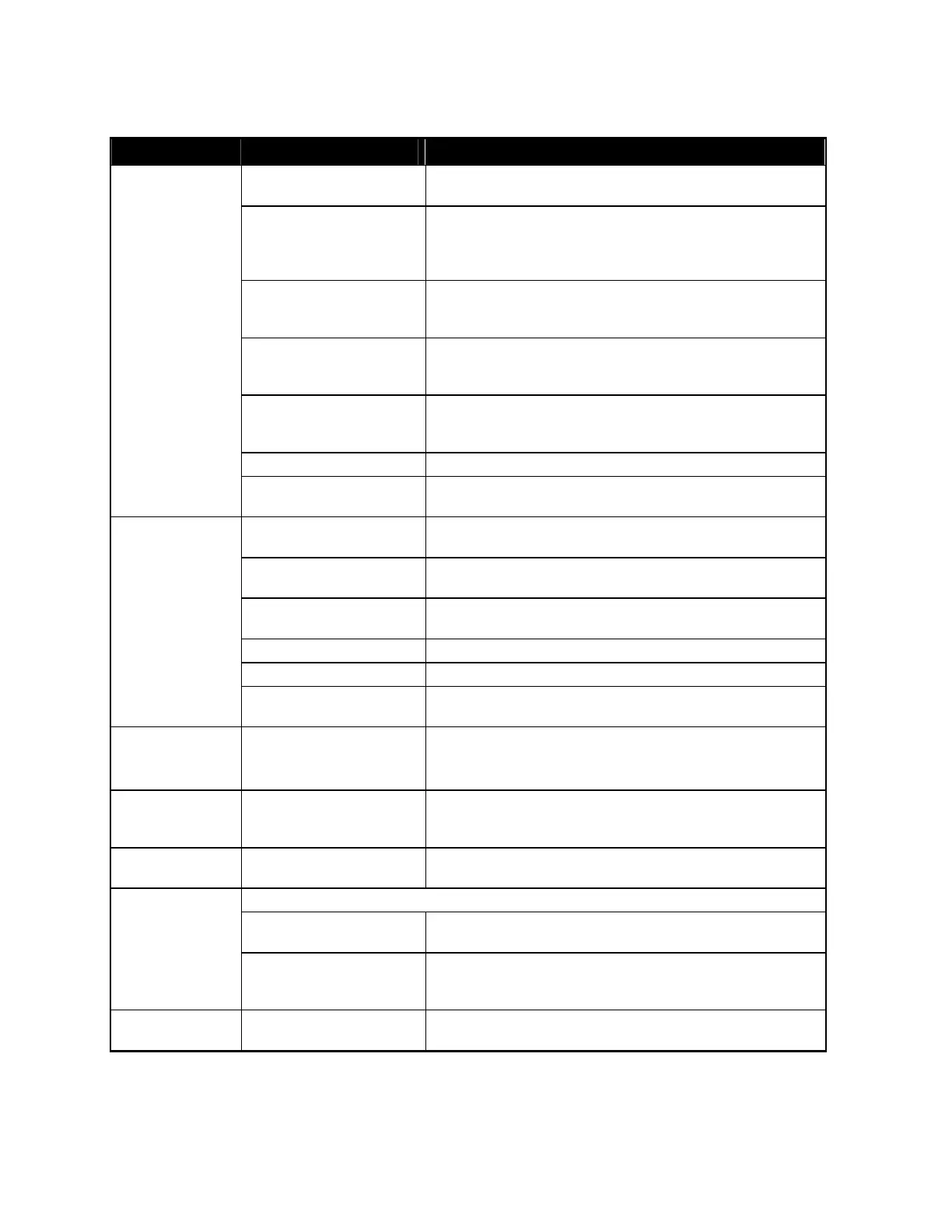

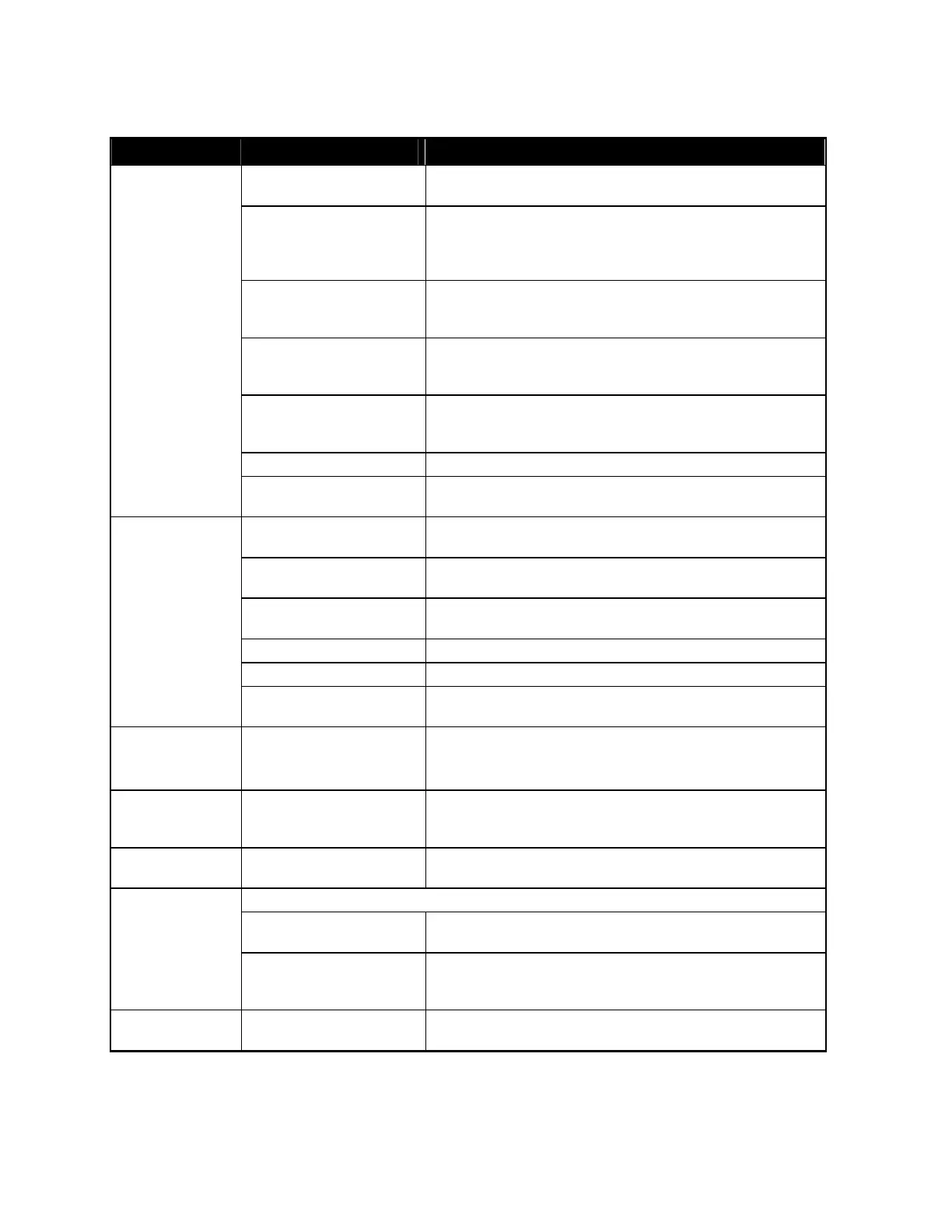

TROUBLE SHOOTING GUIDE FOR BIODISC UNITS

SYMPTOM CAUSE ACTION

Strong odour Excessive build up of

sludge and scum

Desludge the unit.

Grease (white/cream

crust in primary tank

and/or thick, smooth

biomass

1

)

De-sludge unit. If necessary hose off discs. Avoid

excessive use of fats and oils. Please note removal of

Biomass will reduce treatment until new Biomass

establishes.

Chemicals in the system

(very sparse or no

biomass

1

)

In most instances, units will recover naturally from toxic

inhibition events. See general guidance on use of domestic

chemicals.

Excessive laundry use

(thick, stringy whitish

biomass

1

on first section)

Spread out laundry operations. Avoid biological powders

where possible and use the minimum possible amounts of

detergent. .

Unit overloaded

(thick/grey biomass

1

) over

most of rotor

Check section for the process capability of the unit. If in

doubt, contact Klargester.

Rotor stopped See rotor stopped section below.

Drains inadequately

ventilated

Check that there is an open high level vent at the head of

the drains (not tile vent or “Durgo” valve).

Rotor stopped Switched off Check that the motor switch on the panel is in the “on”

position. Re-set if necessary.

Power failure Check the fuse/trip at the supply board. Replace/re-set as

necessary. If the problem persists, contact Klargester.

Wiring fault Have the wiring to control panel checked by a competent

electrician. If the supply wiring is OK contact Klargester.

Drive chain broken Contact Klargester.

Drive motor faulty Contact Klargester.

Loose pulleys on rotor or

gearbox output shaft

Contact Klargester.

Rotor fails to re-

start after a

stoppage

Rotor unbalanced Consider Hosing off excess Biomass on the heavy side of

the rotor. Note removal of biomass reduces treatment.

Loss of rotation

alarm not

operational

Rotor Sensor out of

alignment with bracket

Adjust one or both

Rotor turns

intermittently

Drive motor overheating Contact Klargester.

See strong odour and rotor stopped sections.

Managed flow system

in-operative.

Check that bucket(s) are in place and discharging correctly

into the biozone second stage.

Sludge return pump

inoperative

(ND/NE/NF/NG only)

Contact Klargester.

Unit flooded Drain outlet blocked. Check drain downstream of unit , Check location, ? is unit

correctly installed and recessed

Effluent

discharge not

to required

standard

Loading...

Loading...