21

CS.A80.IST-1 / Rev 1.0 ENGLISH

…the pellet tank goes in over-temperature

If the pellet container is overheated (>85°C), the pellets will not be loaded because the manual reset thermostat cuts in. If this happens during normal

operation, the appliance switches to “THERMAL SAFETY” alarm. It is therefore necessary to reset the “manual reset thermostat” (see “Components

of the appliance”) before switching the appliance on again. To reset, it is necessary to remove the black cap and press the button below.

...lack of power (blackout)

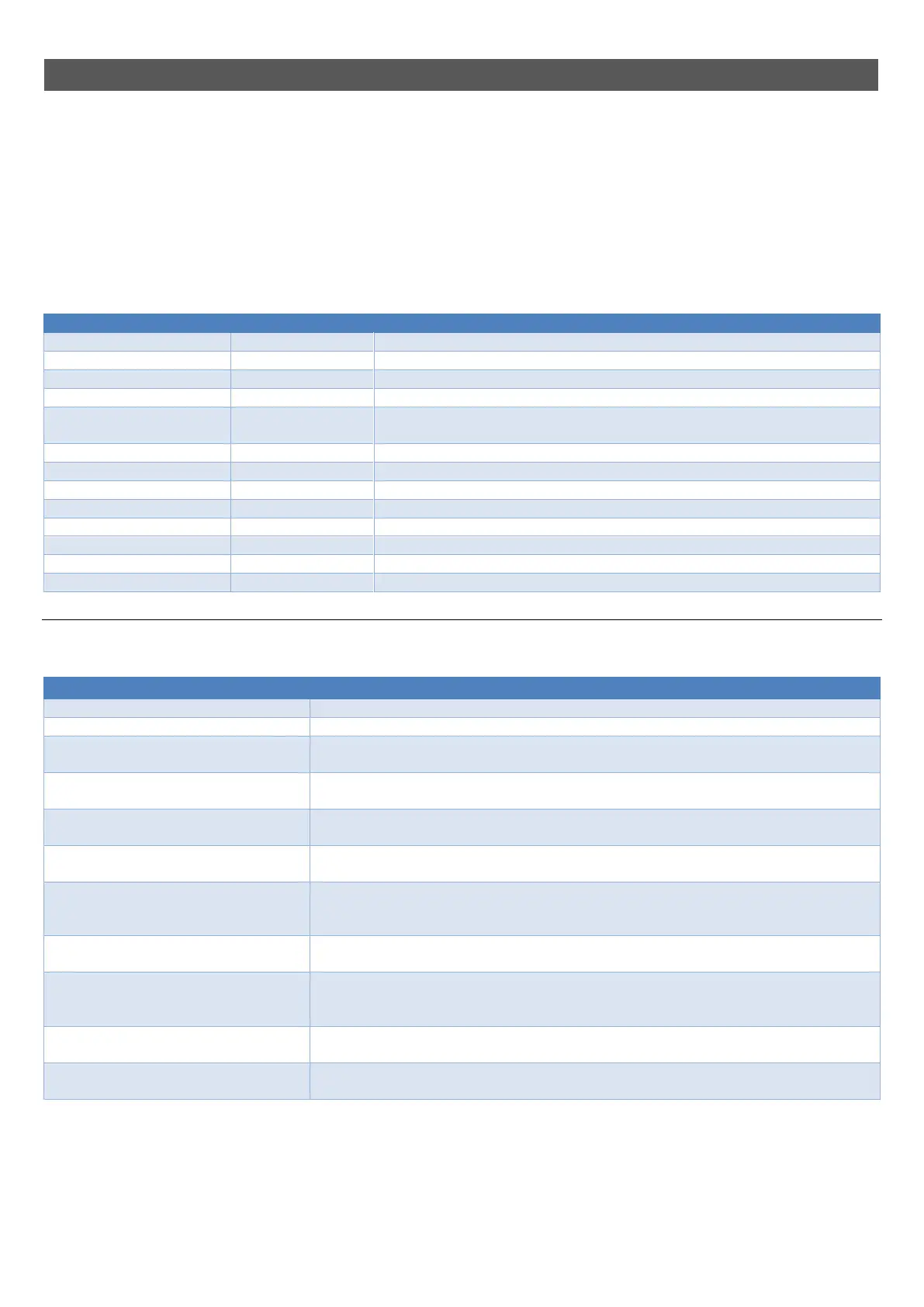

If a power blackout occurs for a shorter time than Pr48, when power is restored, the appliance will immediately re-start in the working mode (recovering

the set working power).

If the outage lasts longer than Pr48, when power is restored, the appliance will enter the “STAND-BY CLE” (stand-by) mode running the entire switch-

off and cleaning cycle until cooling. When this phase is over, the appliance can be restarted resuming work at the set power.

ower restore

CHECK UP

CHECK UP

FLAME STAND-BY

BLACK OUT ALARM

any BLACK OUT ALARM

STABILISATION Duration < Pr48 STABILISATION

STAND-BY CLE with automatic re-

after machine coo

WORK

an

ase

Duration < Pr48 WORK

an

ase

an

ase

STAND-BY CLE with automatic re-

after machine coo

BRAZIER CLEANING Duration < Pr48 BRAZIER CLEANING

STAND-BY CLE with automatic re-

after machine coo

SWITCHING OFF

SWITCHING OFF and after cooli

OFF

Alarm signals

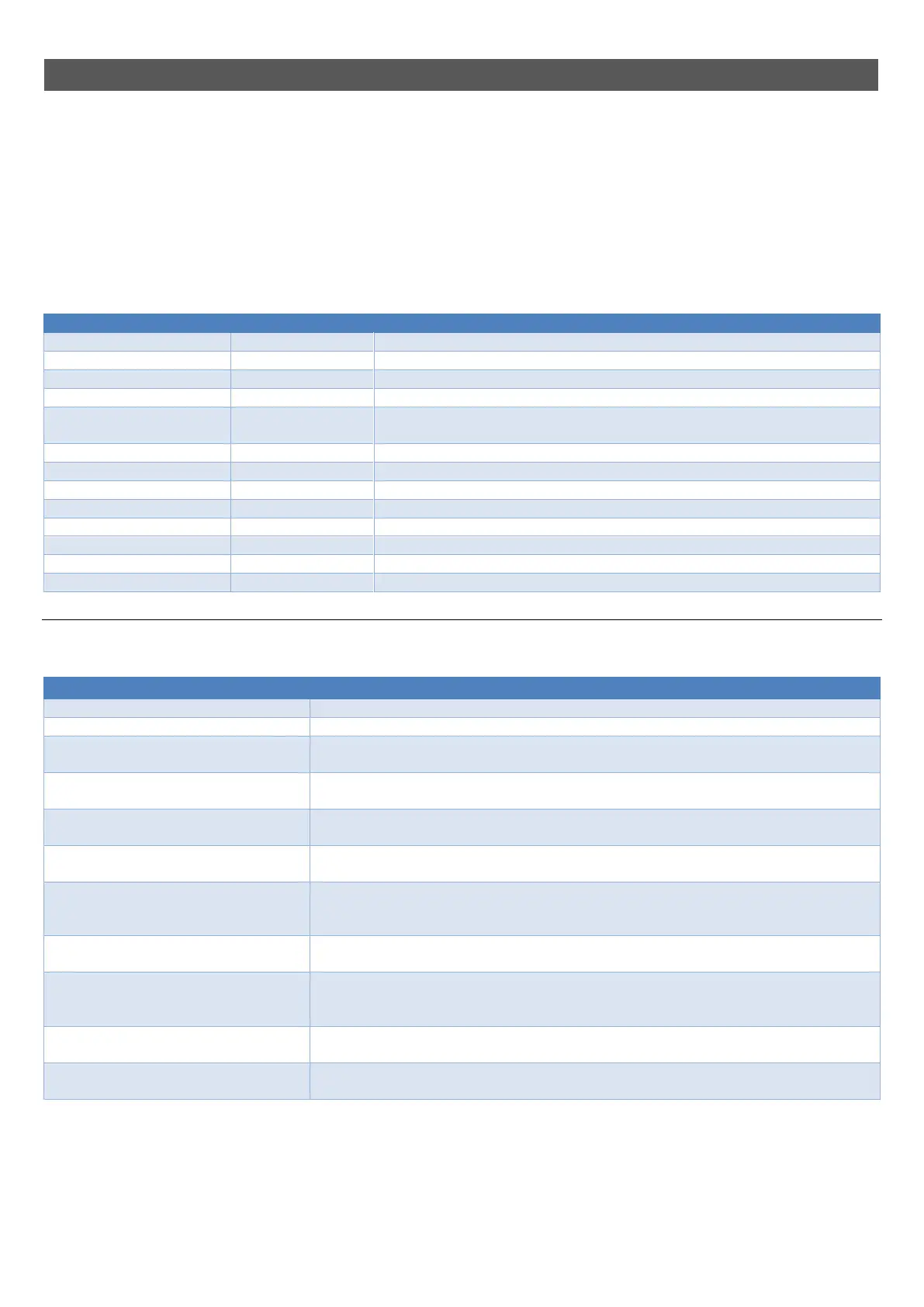

The following table describes the different alarms which may appear.

Black-out alarm. When power is cut off under determined conditions (see“What happens if…”)

AL 02 – TEMP. F.GAS Faulty or disconnected flue gas temperature sensor.

AL 03 – REG. ENCODER

This occurs when the speed detected by the flue gas extractor does not correspond with the set

ed.

AL 04 – NO ENCODER

Flue gas extractor or flue gas extractor encoder faulty. This occurs when the encoder (tachometer)

in the extractor detects an extractor

ed

ual to 0.

AL 05 – IGNIT. FAILED

No ignition. This occurs when the minimum temperature in the combustion chamber (Pr13) is not

reached within the maximum

ition

Pr01

.

AL 06 – PELLET CHECK

Sudden shut-down during the work phase. This occurs when, during the work phase, the

tem

rature in the combustion chamber dr

s below the minimum threshold

Pr13

.

AL 07 – THERM. SAFETY

Temperature safety device. This occurs when the safety thermostat (pellet container over

temperature) or the fire door open or not correctly closed cuts in. If the safety thermostat cuts in the

must be manua

armed

see“Com

nents of the

”

.

AL 08 – DEPRESS.-FAILURE

Poor depression. This occurs when the flue gas pressure switch cuts in due to poor draught in the

flue

e or th

ellet container door is

AL 10 – SCREW FEED SAFETY

This occurs when a continuous loading of pellets takes place (the screw feed gear motor does not

stop for at least 0.2 seconds during the maximum work interval of 8.0 seconds). Before the alarm

r

cuts in and for

ff the power supp

he

ar motor.

AL 11 – INSUFFICIENT DRAUGHT

This occurs when the flow of combustion air is less than the set threshold. NOT USED ON THIS

PRODUCT.

AL 12 – CLEANER FAULT

This occurs when the brazier is not correctly aligned during the cleaning procedure (either during

.

Every alarm causes the appliance to switch-off immediately. The alarm state is reached after the time set on Pr11 (set as default at 90”) and it can be

reset by pressing button 3 for a while. In the event of a fault, contact the Klover Authorised technical assistance centre.

Loading...

Loading...