20

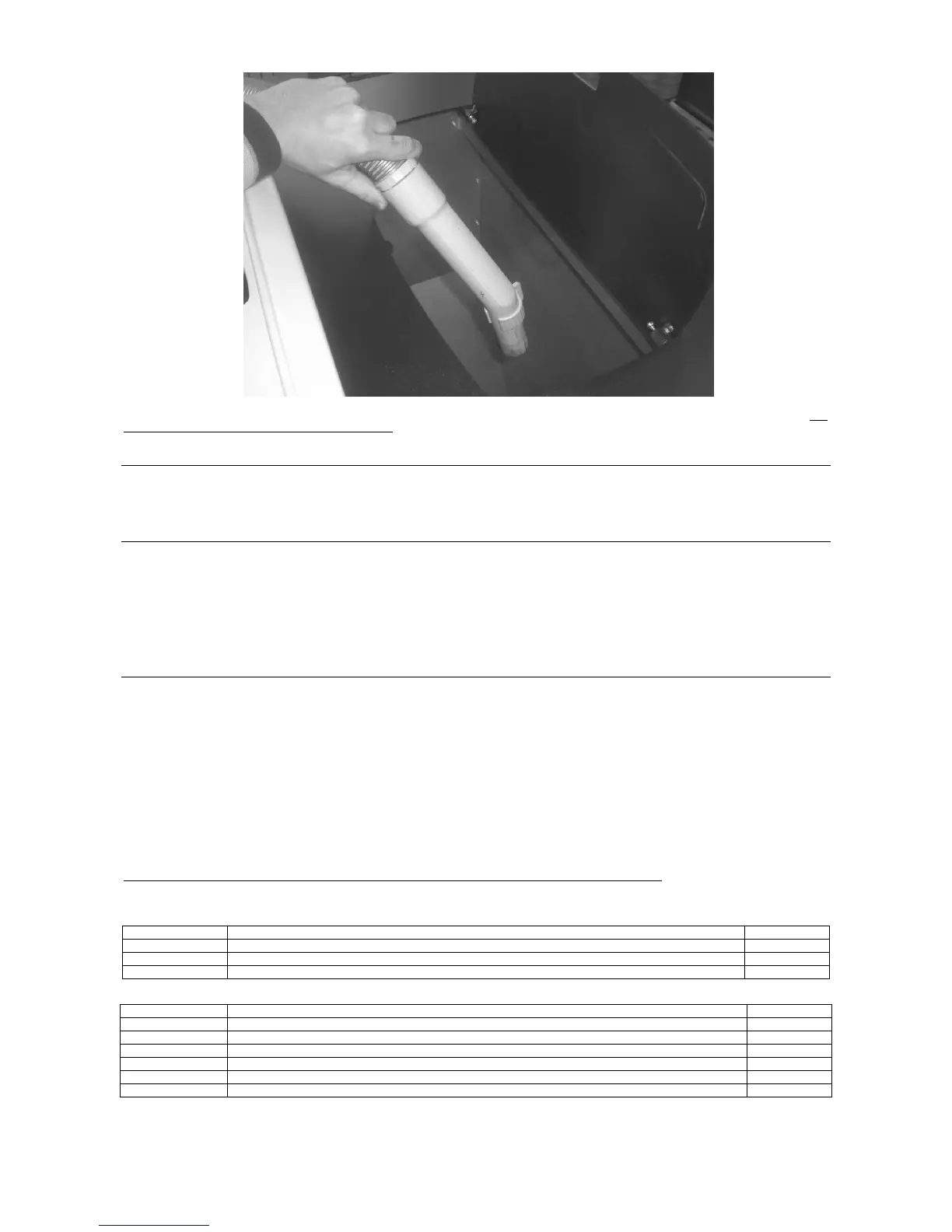

For correct functioning, it is necessary to use a suction device to remove the sawdust deposit on the base of the tank at least every 15 days. The

pellet tank must be emptied at the end of every season.

Cleaning the ceramic glass

Always clean the glass when the stove is off and completely cold. Use a damp cloth and specific detergent for ceramic glasses. Do not use abrasive

sponges.

Cleaning the flue

This operation must be performed at least twice a year, at the start and half way through the winter season, and however when necessary.

It is necessary to check the presence of any blockages in the flue before switching the thermo stove on, following a long period of inactivity.

If cleaning is not performed, the functioning of the thermo stove and its components may be jeopardised.

The frequency of cleaning of the thermo stove and the flue depend on the quality of the pellets used.

USE TOP QUALITY PELLETS TO OBTAIN THE BEST RESULTS.

Maintenance

Punctual and systematic maintenance is a fundamental component for correct functioning, excellent thermal performance and duration of the appliance

through time. Therefore, it is recommended that qualified staff check the thermo stove at least once a year at the beginning of the season.

It is advised to agree an annual contract for product maintenance with the Authorised After-Sales Centre (C.A.T.).

CIRCUIT BOARD PARAMETERS

THE PARAMETERS MEMORISED ON THE CIRCUIT BOARD ARE FUNDAMENTAL FOR THE CORRECT FUNCTIONING OF THE THERMO STOVE

THE PARAMETERS GIVEN BELOW ARE ALREADY MEMORISED IN THE THERMO STOVE INSPECTION PHASE DIRECTLY IN THE FACTORY.

THESE PARAMETERS ARE THE RESULT OF CAREFUL TESTS WITH VARIOUS TYPES OF PELLETS AND MUST NOT BE CHANGED WITHOUT

THE AUTHORISATION OF KLOVER srl, SO AS NOT TO JEOPARDISE THERMO STOVE FUNCTIONING.

ALL LIABILITY IS DECLINED FOR DAMAGE CAUSED BY INCORRECT INTRODUCTION OF THE PARAMETERS.

CIRCUIT BOARD PARAMETERS PROGRAMMED IN THE FACTORY

Preload parameters

Loading...

Loading...