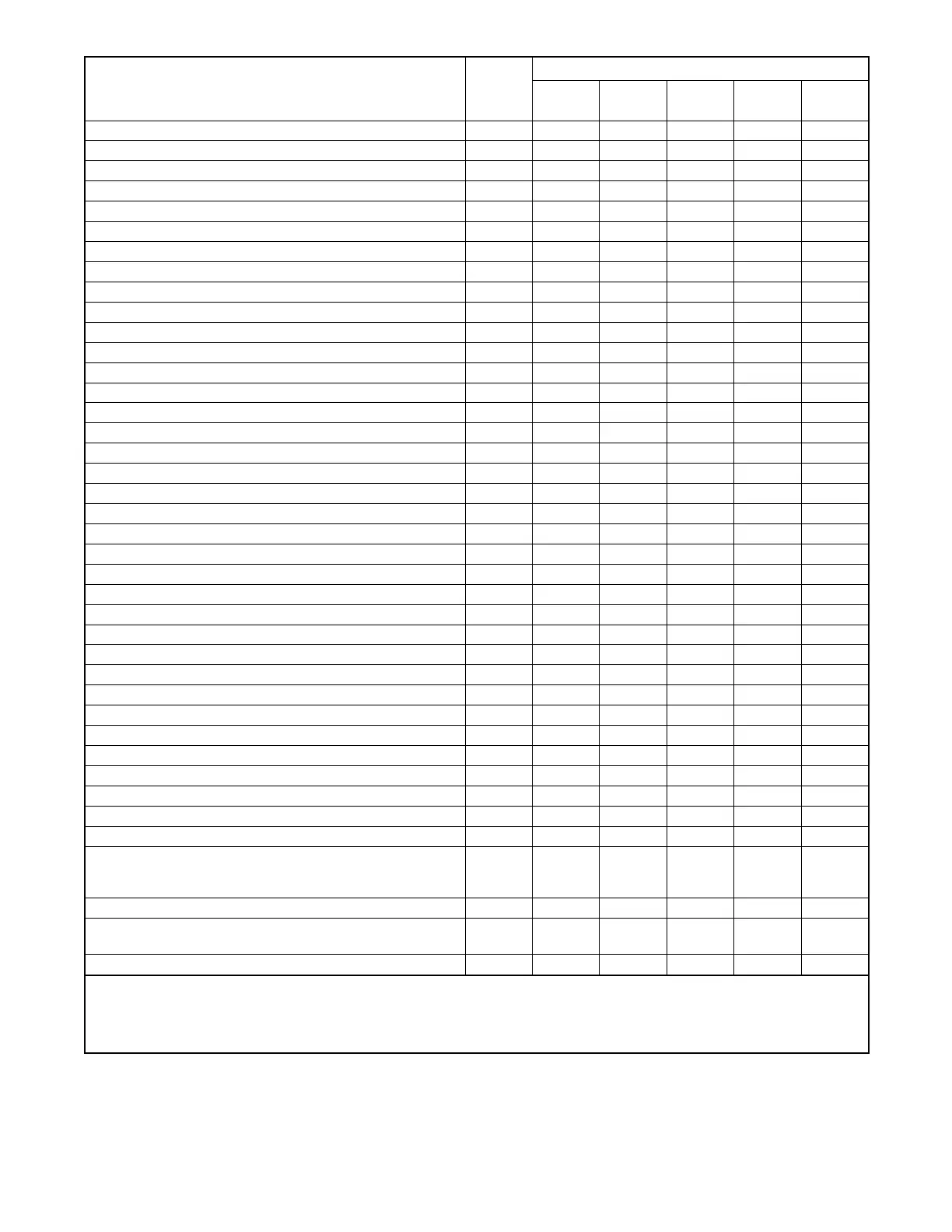

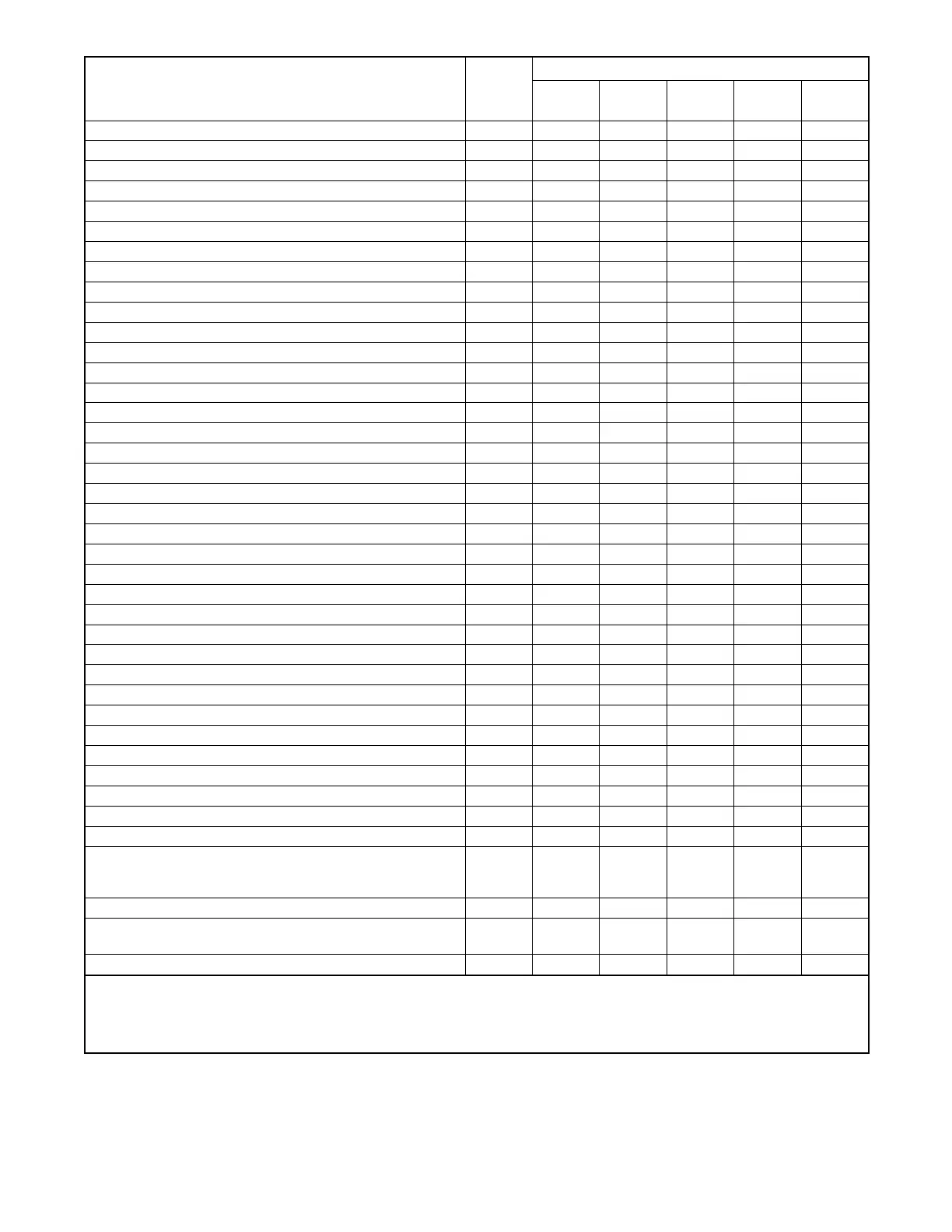

TP-6519 8/1718 Section 2 Scheduled Maintenance

System Component or Procedure

See

Section

Procedure

Visually

Inspect

Check Change Clean Test

Fuel

Flexible lines and connections Q R

Main tank supply level (LP) W

Fuel piping Y

Lubrication 2.2

Oil level 2.2.2 8orE

Change oil 2.2.4 Y or 150

Replace filter 2.2.4 Y or 150

Crankcase breather hose Y or 500

Oil cooler 2.2.5 Y Y or 100

Cooling 2.5

Air ducts, louvers Y Y

Exhaust System 2.7

Leakage W W

Insulation, fire hazards Y

Obstructions or combustible materials near exhaust outlet W

DC Electrical System

Battery charger operation, charge rate M

Remove corrosion, clean and dry battery and rack 2.8 Y Y

Clean and tighten battery terminals and inspect boots Y Y

Tighten DC electrical connections Y

AC Electrical System

Tighten control and power wiring connections Y

Remote control system, if equipped M

Visible wear or damage Q

Wire abrasions where subject to motion 6 months 6 months

Wire-cable insulation condition 3Y or 500

Engine and Mounting

Visible wear or damage W

Air cleaner service * 2.4 150 300

Spark plugs 2.3 150 300

Replace stepper motor coupling and bushing 2.6 500 (D)

Generator

Visible wear or damage Q

Exercise generator set W

Brushes and collector ring 5.5, 5.6 Y(D) Y(D)

Measure and record resistance readings of windings with

insulation tester (Meggerr, with SCR assembly or rectifier

and load leads disconnected)

3Y (D)

General Condition of Equipment

Evidence of vibration, leakage, deterioration, unusual or

excessive noise or temperature

W W W

Interior of sound enclosure Q Q

* Service more frequently under extremely dusty/dirty conditions.

Meggerr is a registered trademark of Biddle Instruments.

EEachuse

W Weekly

M Monthly

Q Quarterly

Y Yearly

Number = hours of operation

D Authorized distributor/dealer only

R Replace as necessary

S/M Service Manual

Figure 2-1 Service Schedule

Loading...

Loading...