TP-6519 8/17 63Section 5 Component Testing and Adjustment

Governor System Operation Test Procedure

1. Verify that the carburetor throttle linkage is

connected to the stepper motor as shown in

Figure 5-22.

2. Look for broken or loose wiring or plug connections

if the stepper motor moves erratically. C heck the

condition of the throttle linkage, and verify that the

throttle plate closes completely.

3. Check the operation of the stepper motor at

startup.

a. If the throttle moves to the fully open throttle

position and then steps to and remains in the

fully closed position, the engine speed input is

probably missing. The engine starts and then

shuts down on an overspeed fault. Proceed to

step 4 to check the magnetic pickup.

b. If the throttle linkage moves erratically or not at

all at during startup, proceed to step 8 to check

the stepper motor.

4. Stop the generator set and check the resistance of

the magnetic pickup.

a. Stop the generator set. Remove housing

panels as required to gain access to the front of

the engine.

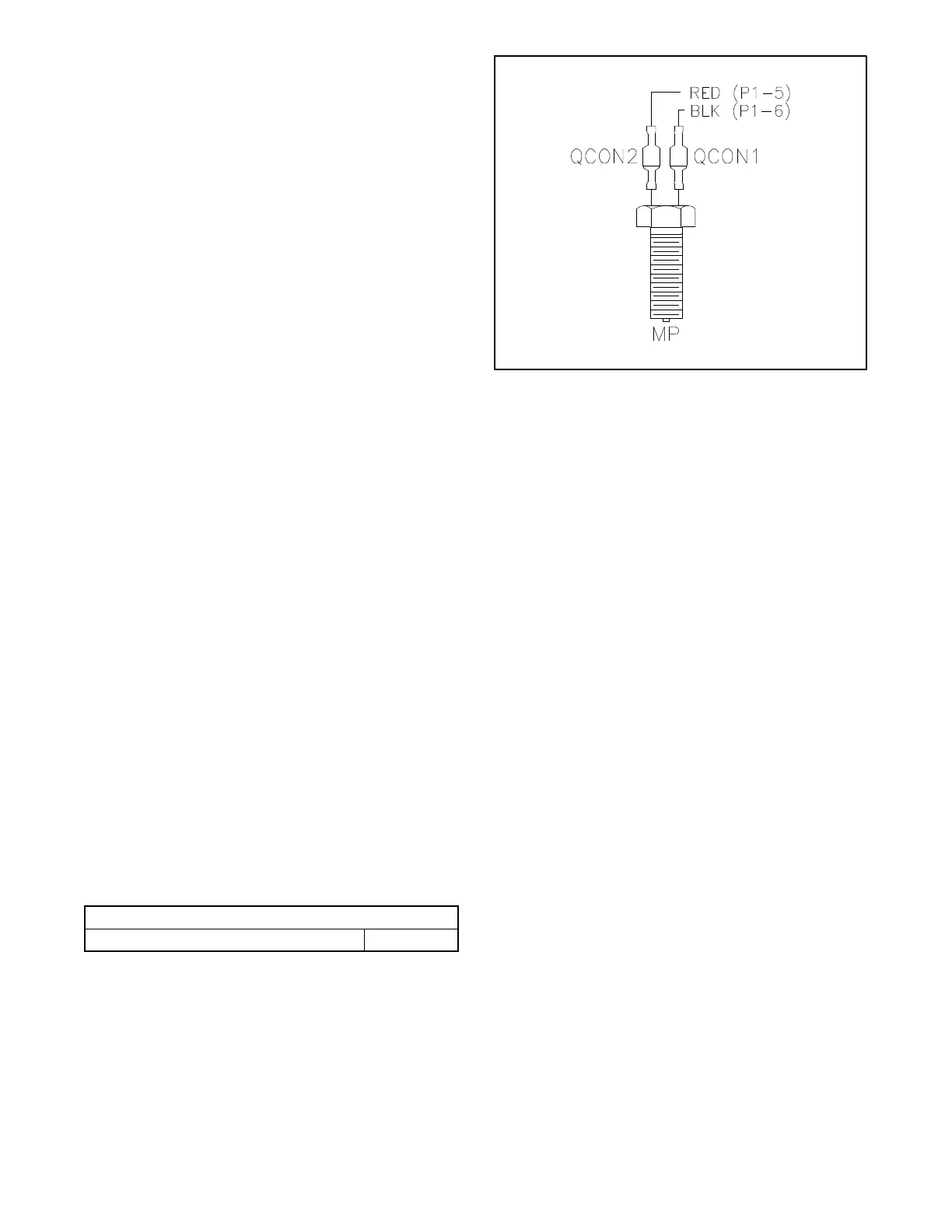

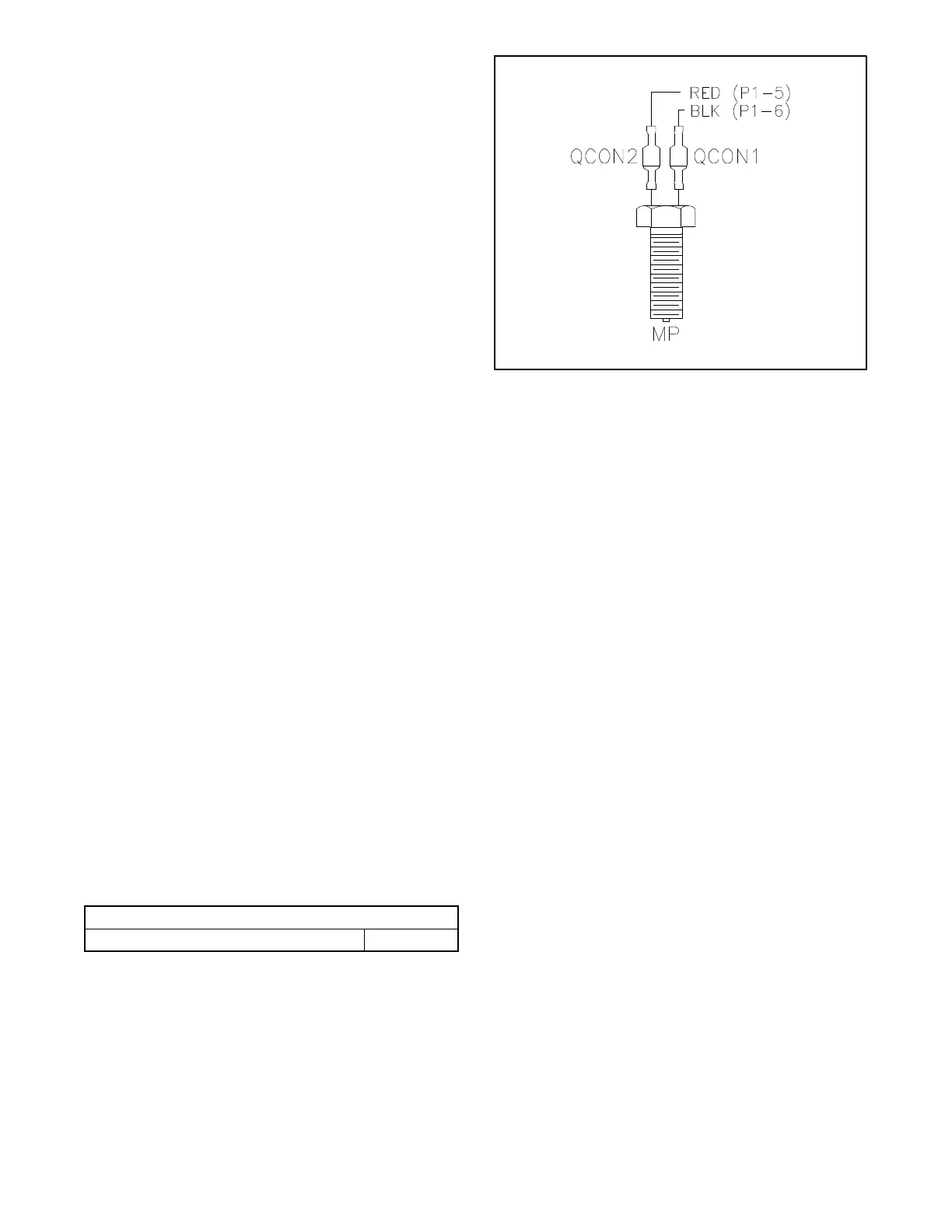

b. Disconnect the magnetic pickup at QCON1

and QCON2. The magnetic pickup must be

isolated from the generator controller to allow

an accurate resistance measurement.

c. Measure the electrical resistance through the

magnetic pickup at QCON1 and QCON2. See

Figure 5-25.

d. Compare the resistance measurement to the

value shown in Figure 5-24. If the resistance is

outside of the specified range, replace the

magnetic pickup.

e. Reconnect QCON1 and QCON2.

Magnetic Pickup Resistance

Resistance across QCON1 and QCON2 1.3 -- 1.9 k

Figure 5-24 Magnetic Pickup Resistance

6519

Figure 5-25 Magnetic Pickup Leads

5. Verify the operation of the magnetic pickup by

connecting a v oltmeter to the magnetic pickup

leads. See Figure 5-25.

If the air gap is correct, the voltage should be

1.75 volts AC minimum during engine cranking.

6. If the voltmeter displays less than 1.75 volts AC,

check the air gap as described in the following

steps before replacing the sensor. Verify that the

magnetic pickup air gap is 0.5 mm (0.020 in.).

Measure the air gap at 3 or 4 places to get an

accurate reading. See Figure 5-26.

a. Stop the generator set. Remove housing

panels as required to gain access to the front of

the engine.

b. Remove the engine blower housing.

c. Use a feeler gauge to check the gap. The gap

should be 0 .5 mm (0.020 in.).

d. Adjust the air gap, if necessary, by loosening

the locknut and turning the pickup. See

Figure 5-26.

e. Hold the pickup in position and retighten the

locknut.

Loading...

Loading...