260 Section 14 Load Management TP-6953 7/19

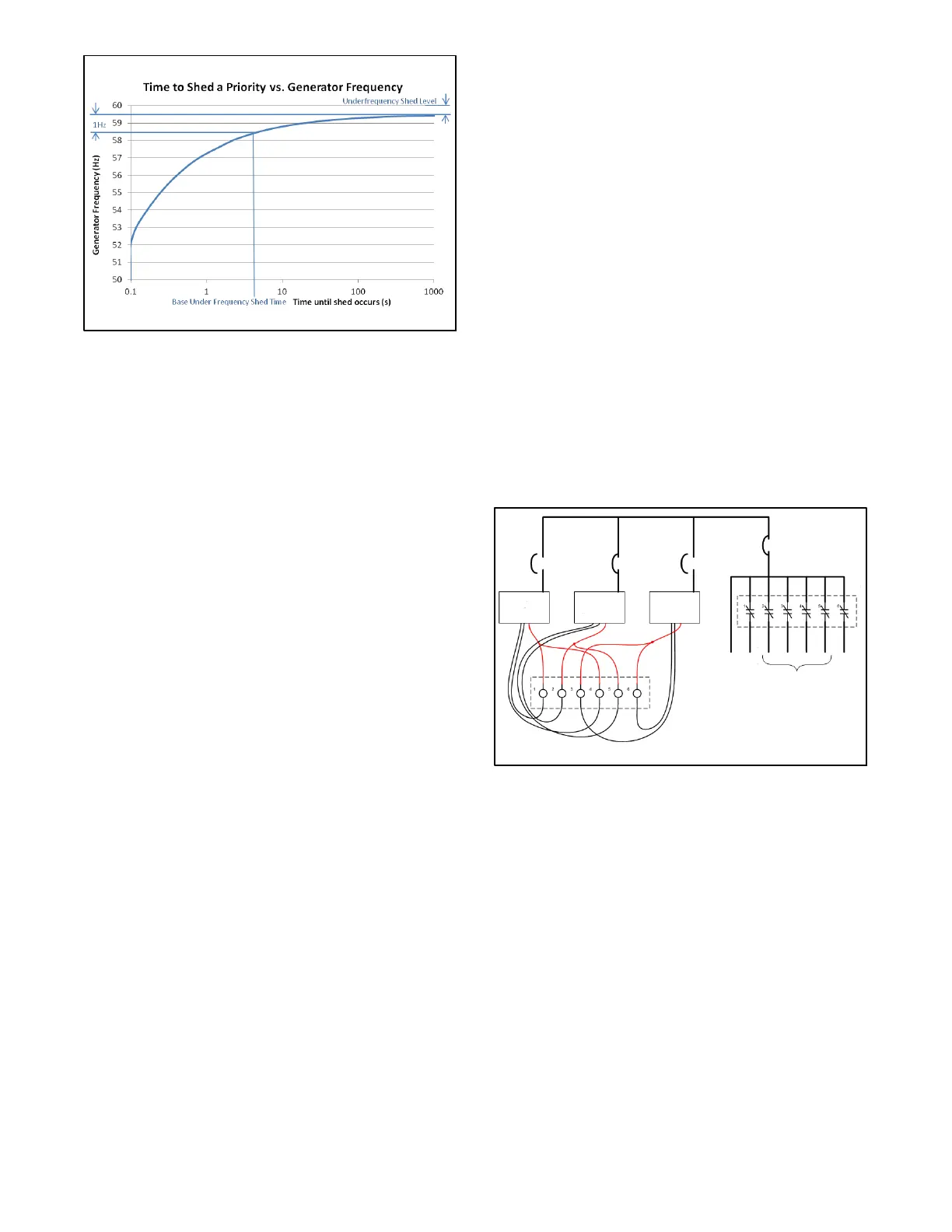

Figure 14 -7 Load Shed Timing Based on Generator

Frequency

(Underfrequency Shed Level = 0.50 Hz,

Base Underfrequency Shed T ime = 5 sec.)

If the generator was overloaded to 11 0% of

capacity and this caused the generator frequency

to dip to 58 Hz, Underfrequency Shed would cause

priority6toshedin2seconds(OverloadShed

would also be active, but would require 5 seconds

to shed, so it would only be 40% shed).

When removing priority 6 decreases the load to

105% and causes the frequency to recover to

58.5 Hz, the curve in Figure 14-7 would indicate

that priority 5 would shed in 5 seconds, but

Underfrequency Shed has acceleration of 0.56,

meaning that each priority sheds in half as much

time as the previous priority if the condition is not

cleared, hence priority 5 would actually shed in

2.5 seconds (Overload Shed would have a total

time of 7.5 seconds, meaning that another 33%

would be added to the 40% shed condition, making

priority 4 73% shed due to overload).

When removing priority 5 decreases the load to

93% and allows the frequency to recover to 59.2 Hz

in the next two seconds, the curve in Figure 14-7

would indicate that the time to shed would be about

60 seconds, but the acceleration drops it to

0.25* 60 = 15 seconds. Even at that load, the

generator is allowed to recover to rated frequency

by the underfrequency shed logic, but the overload

shed logic will still cause the priority 4 to shed in

another 15 seconds (45 sec time to shed at 93%

load, and shed already 67% complete).

14.2.2 Sequence of Operation—

Paralleling System

This sequence follows the operation of a normal

paralleling system which uses Load Management. The

Load Management log ic uses the paralleling bus

frequency and the paralleling bus percentage of rated

capacity to determine a need to add or shed load. A

generator does not have to be running to support Load

Management.

When a start signal is applied to any of the generators in

the paralleling system, all the generators that are in auto

and have no shutdown faults will start and all the load

priorities will shed. T his shed is intended to remove

excess load from the system so that a single generator

can support it.

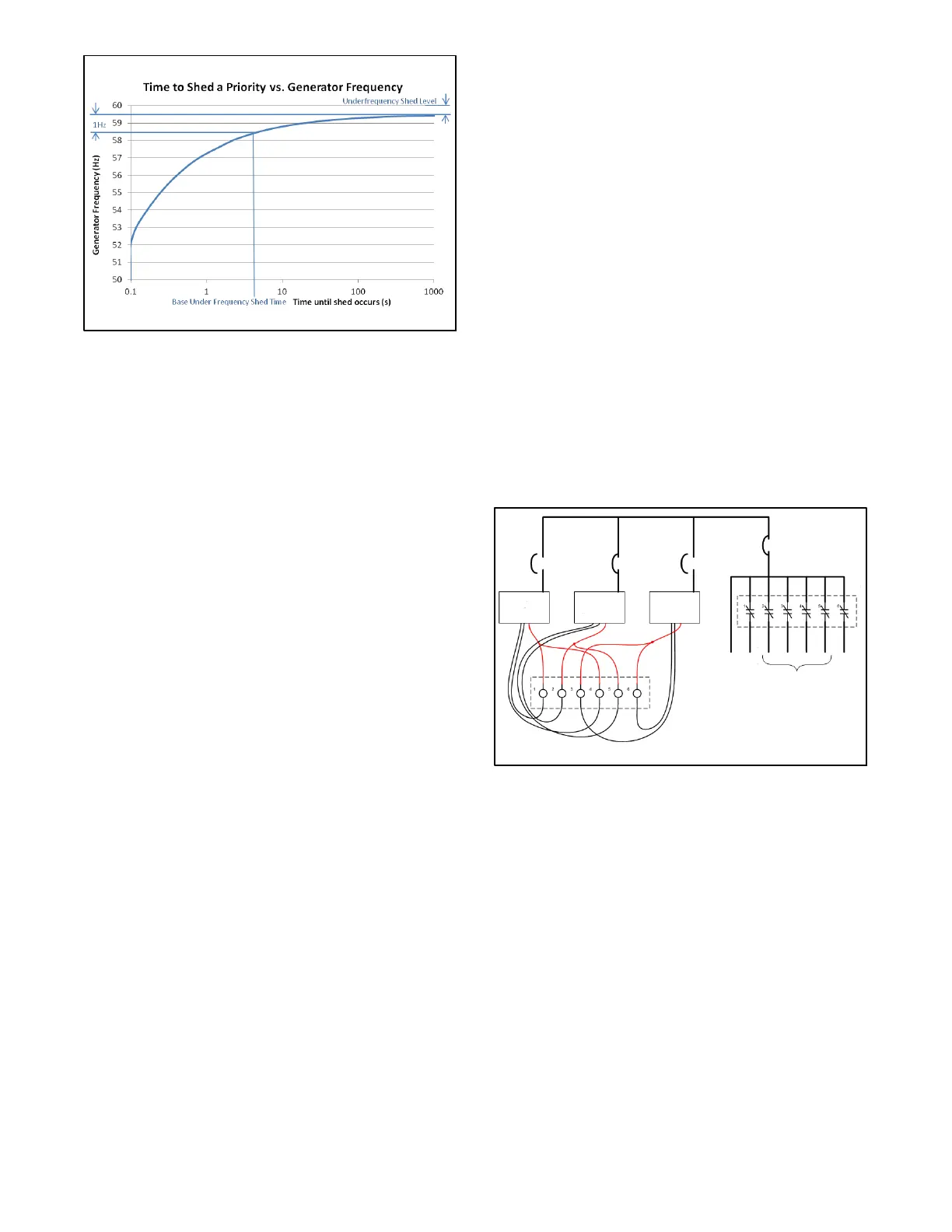

Figure 14-8 illustrates the system after the first

generator has reached rated voltage and frequency and

has closed to the paralleling bus (any of the generators

can be the first to close, d epending on which generator

reaches rated voltage and frequency first).

25kW

Critical

loads

Most

important

non-

critical

loads

Least

important

non-

critical

loads

Additional

non-critical

loads

Load

Shed

Panel

Load

Shed

Panel

Generator #1

(50kW rating)

18kW 3kW 10kW 12kW 5kW

25kW

8kW

Generator #2

(50kW rating)

Generator #3

(50kW rating)

Figure 14-8 One Generator Energizes the Paralleling

Bus

The load on the first generator to connect to the

paralleling bus is merely that of the critical loads.

The time t o Add Priority 1 can be determined from

Figure 14-9 based on a 50% generator load. The curve

indicates approximately 1500 seconds (25 minutes)

before priority 1 will add.

After synchronizing to the paralleling bus, generators #1

and #3 will close their paralleling breakers, providing a

total of 150 kW of capacity to the paralleling bus. The

25 kW load is only 17% of the capacity of the bus with all

three generators supplying it, hence the time to add a

priority drops to 26 seconds.

When priority 1 adds, the output from generator #1 that

drives the load shed priority will de-energize.

Loading...

Loading...