TP-6953 7/19 137Section 7 Troubleshooting

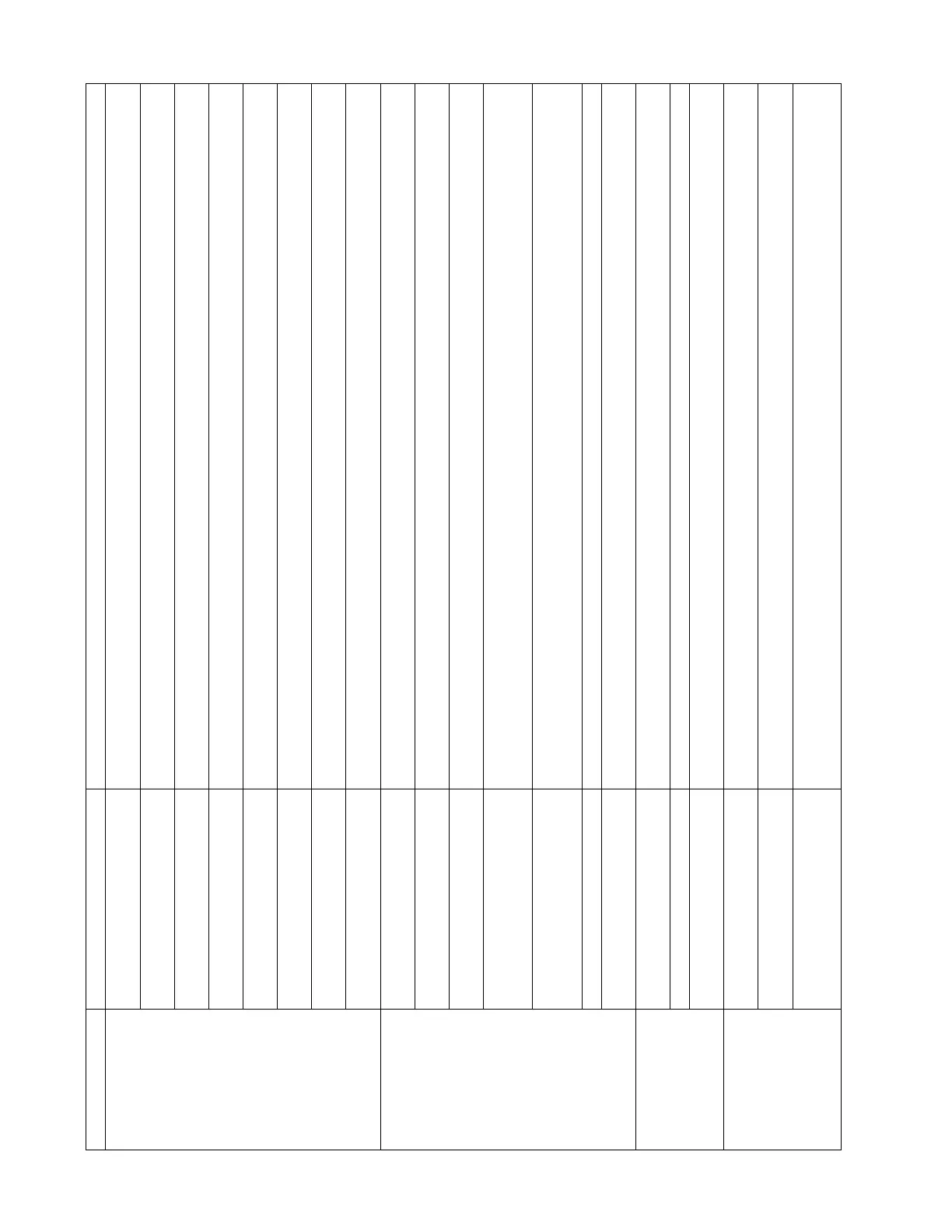

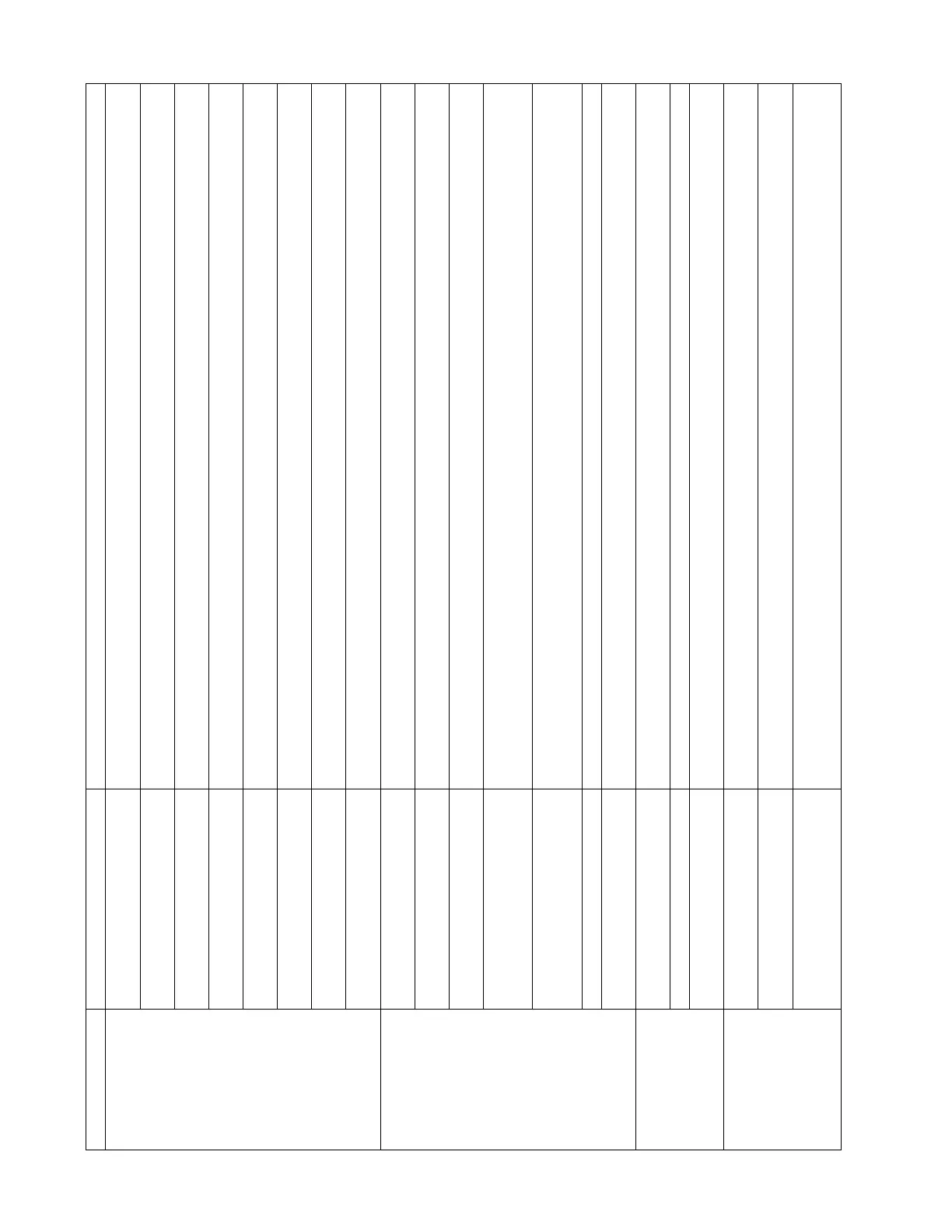

7.10 Troubleshooting—Voltage Regulator

Symptom Potential Causes Troubleshooting

No voltage

Breaker status is indicating closed. Ensure that Connected to Bus under Parallel Metering is set to False. (Note: This condition will have similar results in a

paralleling or standalone application). If shown as True, verify that BSN and BSP wires are not connected.

Loose wiring between controller and

LED board or wound field activator.

Check wiring between controller and LED board. Perform Flashlight test. If alternator produces no voltage, look for bad wires

or connections. If no bad connections are found, continue with alternator troubleshooting.

Activator board failure on alternator. If alternator produces no voltage, look for bad wires or connections. If no bad connections are found, continue with alternator

troubleshooting in Section 10 or 11.

Broken wire or failed winding in

alternator.

If alternator produces no voltage, look for bad wires or connections in the alternator. If no bad connections are found,

continue with alternator troubleshooting in Section 10 or 11.

Speed sensor. Verify that the controller is seeing speed above the crank disconnect level. The voltage regulator is not enabled until the

engine speed exceeds the crank disconnect level.

No ECM communications. If the engine speed is received from the engine ECM, the voltage regulator requires a CAN message listing the speed as

above the crank disconnect speed before the voltage regulator is enabled.

Open circuit breaker. A tripped circuit breaker on the generator will result in no voltage to the load without a failure on the generator. If the

generator controller is measuring voltage, the breaker is probably tripped.

Reversed wiring to the activator

board.

Note a 0.7- 1.0 V output to the board (3B to 5B) instead of a 1.2- 1.5 V output.

Irregular voltage

output

Loose wiring between controller and

LED board or wound field activator.

Check the wiring between the controller and the LED board. Perform Flashlight test. If alternator produces no voltage, look

for bad wires or connections. If no bad connections are found, continue with alternator troubleshooting.

Broken wire or failed winding in

alternator.

If alternator produces no voltage, look for bad wires or connections in the alternator. If no bad connections are found,

continue with alternator troubleshooting in Section 10 or 11.

Loose voltage sensing wiring to

controller.

Verify wiring to voltage sensing of controller.

Incorrect Personality Profile in

controller.

Check Alternator Manufacturer setting:

FRII or FRX alternators should use Alternator Manufacturer = Kohler,

4D Alternators should use Alternator Manufacturer = Kohler Wound Field

Incorrect voltage regulation gains. Verify voltage regulator gains:

Normal Gain = 128,

Stability = 128

Incorrect Volts/Hz settings. Verify that Volts/Hz Cut-In (knee) frequency is at least 0.5Hz below full-load operating frequency.

Engine hunting problem. Verify that engine is operating stably. Verify fuel supply, pressure regulator (if equipped) fuel filters (if equipped), water in fuel

indicator (if equipped).

Voltage decreases as

load increases and

does not recover

Reactive droop is set too high. Reactive droop should be set between 0.0% and 1.0% in single-generator applications.

Reactive Droop should be set between 1.0% and 4.0% in paralleling applications.

Voltage regulator gain is set too low . Voltage regulator gain should be set to at least 16.

Missing wiring between alternator

and activator board.

The activator on FRX and 4D alternators requires 3-phase input (all three wires should be connected).

Voltage dips when

load is applied, but

recovers relatively

quickly

Normal operation. Sudden increases in reactive load on the generator will cause the voltage to dip momentarily. Large increases in load on the

engine (real load) will cause the frequency to dip, resulting in voltage dip from underfrequency unload in voltage regulator.

Excessive motor loading. Large motor loads will cause the voltage on the generator to dip significantly. To determine the motor lock-rotor kVA that a

generator will support at a given voltage dip, consult the data sheet for the alternator.

Large transformers, lighting

ballasts, UPS battery chargers, or

VFDs powering up.

Many non-linear devices will demand very large inrush currents until an internal power bus is charged.

Loading...

Loading...