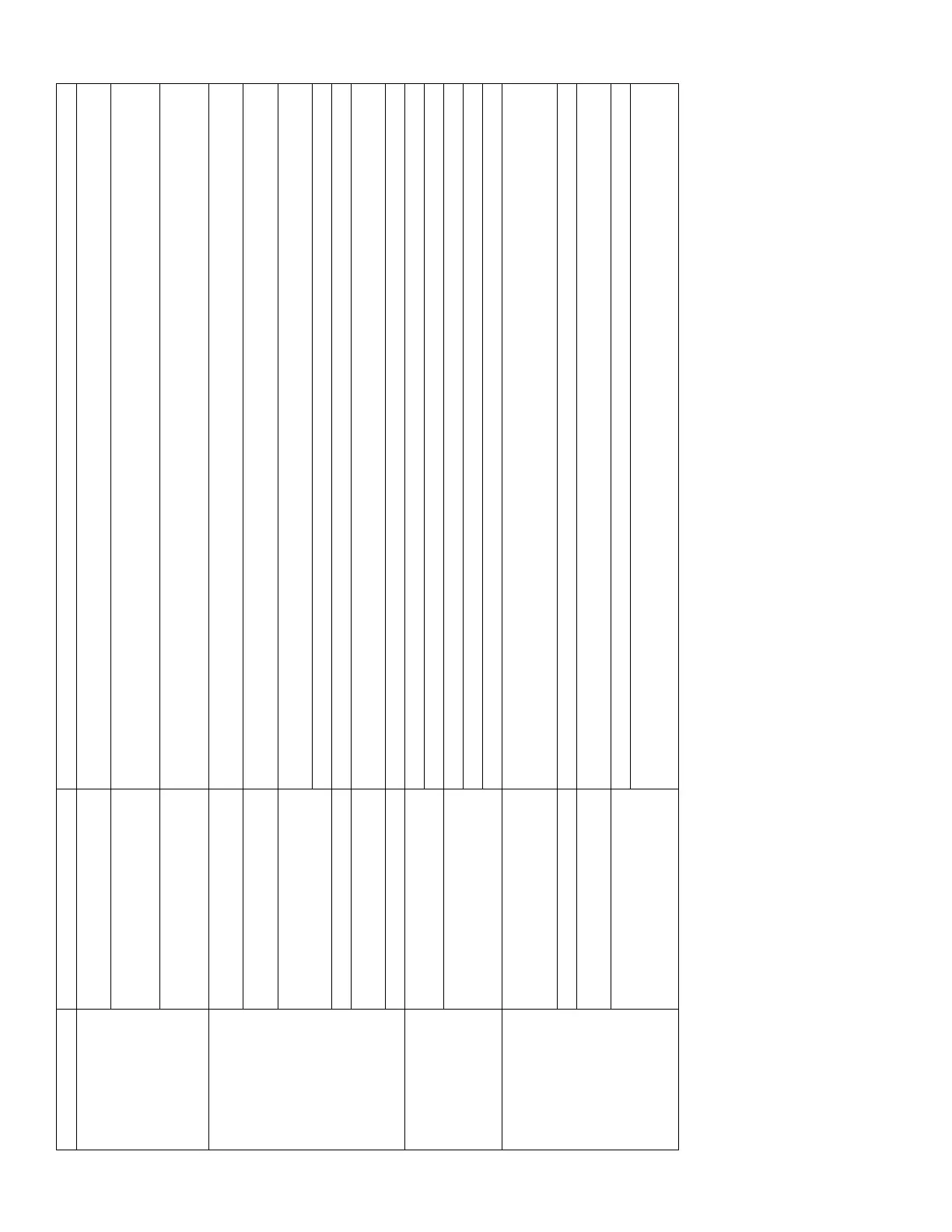

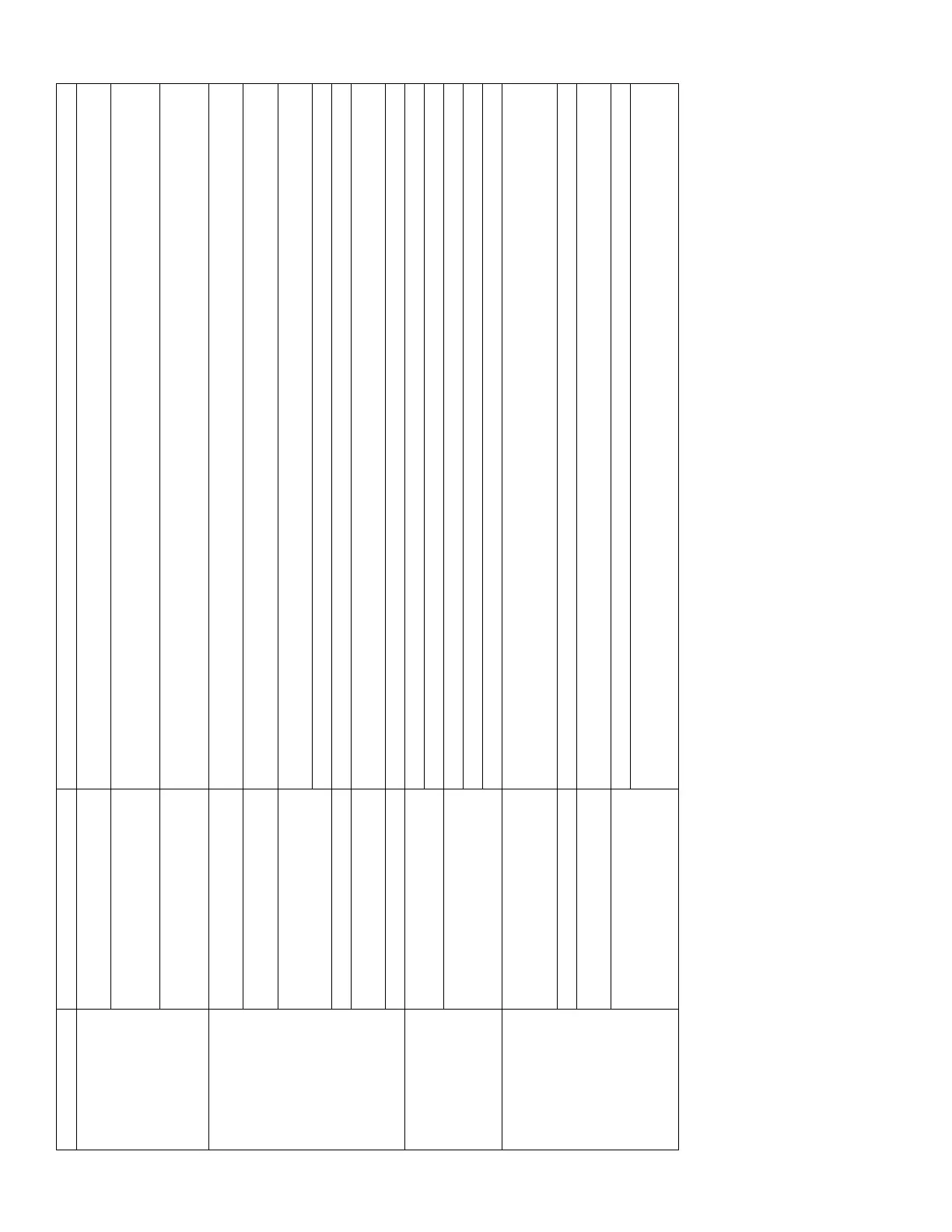

TP-6953 7/19138 Section 7 Troubleshooting

Symptom Potential Causes Troubleshooting

Voltage overshoots

when load is removed

Normal operation. Sudden decrease in reactive load on a generator will result in short-duration voltage spikes on the alternator. The spike

duration and magnitude is minimized by the fast response alternator.

Large motor tripping off while

attempting to start.

Ensure that the motor is within the capability of the generator. Compare the motor locked-rotor kVA with the appropriate

voltage dip on the alternator data sheet. It is not recommended to attempt to start a motor with a locked-rotor kVA that is

greater than what would cause a 35% voltage dip.

Large transformers or lighting

ballasts disconnecting from the

generator.

Lighting controllers and other ’smart’ devices can cause strange loading scenarios on generators. It may be necessary to

reconfigure the devices in order to get the system to operate as intended.

Excessive voltage

Incorrect connection of voltage

sensing leads.

Voltage sensing leads on the DEC3500 should be connected to L1, L2 and L3 of the generator. Center Taps V7, V8 and V9

are not to be used with this controller.

Missing/disconnected voltage

sensing lead.

The controller regulates the average of the three line voltages to the target. If a single phase is lost, the controller will attempt

to bring the average back to match the target.

Incorrect controller configuration.

If the alternator is wired for single-phase and the controller is configured for three-phase, the generator will output excessive

voltage.

If the controller is configured for too high of voltage, the generator will output excessive voltage.

Damaged activator board. If the activator board fails to a full-on condition, the alternator will probably produce excessive voltage.

Damaged controller. If the controller fails to request a full-on condition from the activator board, the alternator will probably produce excessive

voltage.

Damaged alternator. If the alternator develops an internal short circuit on one of the windings, the other windings may generate excessive voltage.

Unstable Voltage

(Single Generator)

Unstable only at no load.

Check lead connections to studs for activator board.

Ensure good connection for 3B and 5B wiring to LED board and in controller connector.

Unstable under load.

Decrease reactive droop.

Check engine speed stability.

Check for rapidly varying load.

Unstable Voltage

(Parallel Operation)

Unstable only in parallel, external

voltage controls:

1. External control gains too high. Verify instability of voltage bias.

2. Internal droop setting too low. Verify droop requirements of external controls.

3. External controls not

providing voltage control.

May require calibration, target, and/or droop adjustment in the controller.

Unstable in parallel, PGEN

paralleling.

Adjust voltage regulator gain down to 32 and stability down to 64.

Adjust kVAR sharing gains (decrease I gain, increase D gain, decrease P gain).

NOTE: These changes will slow the response of kVAR control.

Verify that the system still corrects kVAR quickly enough on breaker closure.

Loading...

Loading...