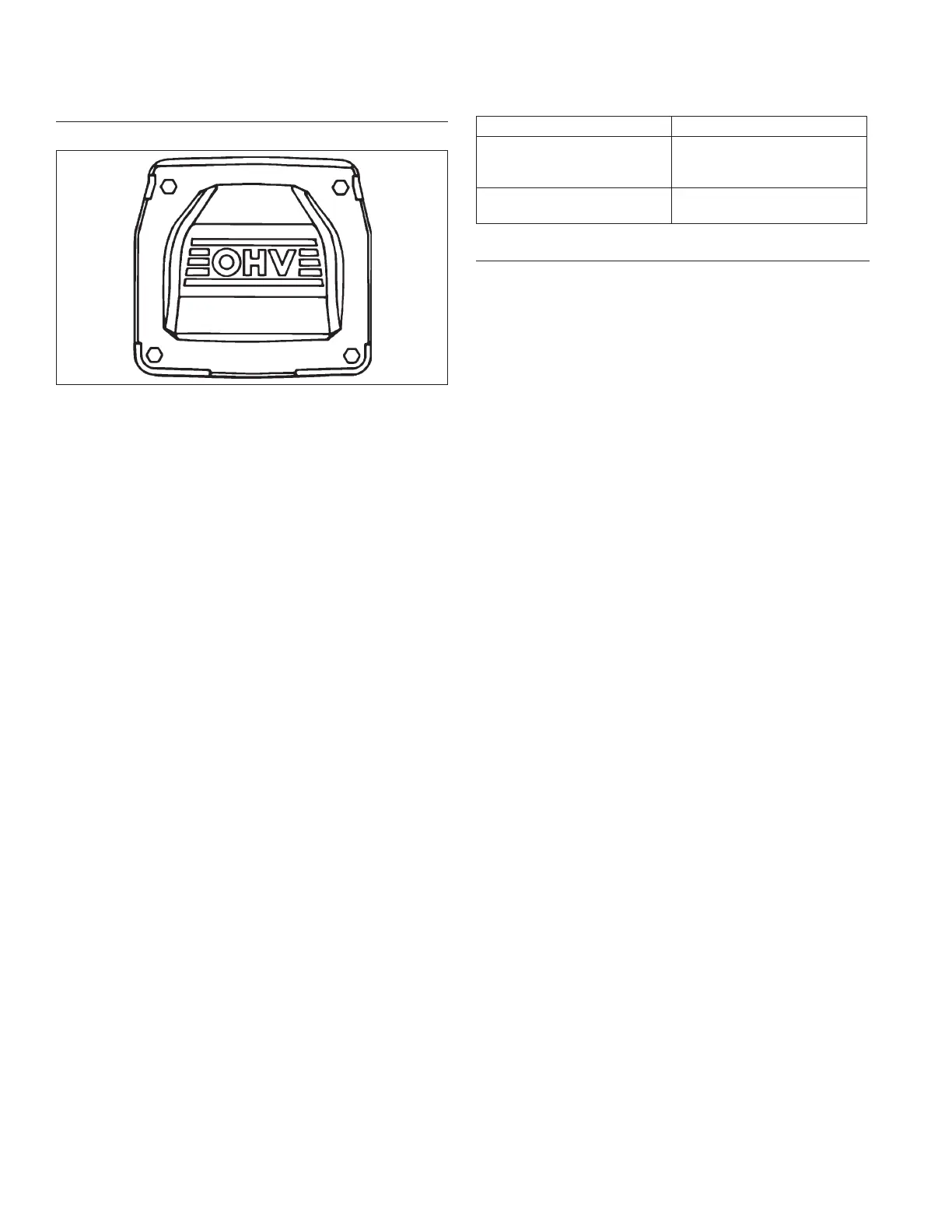

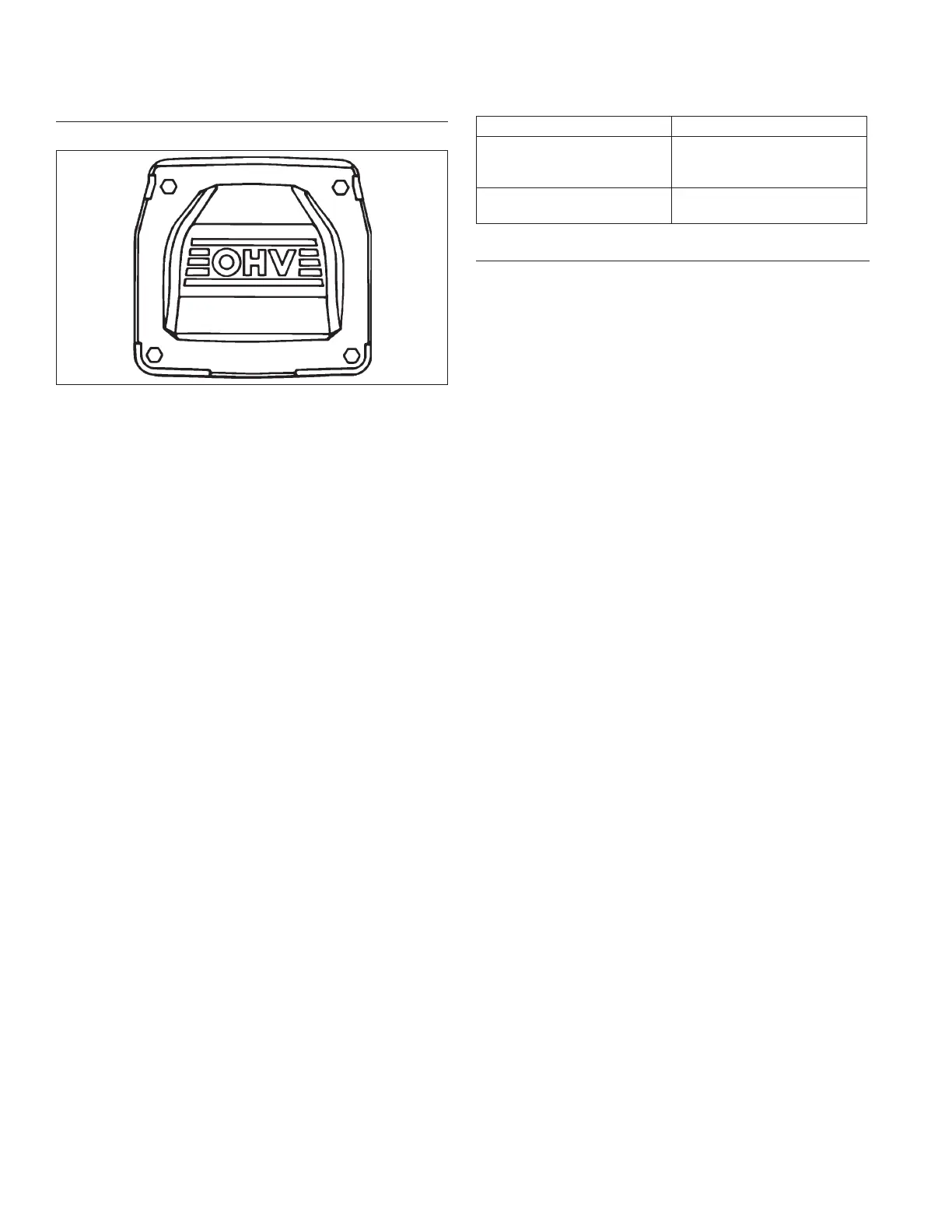

Install Valve Covers

Torque Sequence

1

2

3

4

NOTE: Do not scrape old RTV sealant (if used) off

sealing surface of cylinder head as this could

cause damage and result in leaks. Use of gasket

remover solvent (paint remover) is

recommended.

NOTE: Second fastener may secure fuel pump bracket

on earlier models.

Three valve cover designs have been used. First type

used a gasket and RTV sealant between cover and

sealing surface of cylinder head. Second type had a

black O-ring installed in a groove on underside of cover

and may have metal spacers in bolt holes. Latest design

uses a yellow or brown O-ring, with bolt hole spacers

molded in place. Tightening torque diff ers between

gasket and O-ring style covers. Kits are available for

converting to latest O-ring type covers. Diff erences are

pointed out in following installation steps.

1. If using gasket or sealant type cover, prepare sealing

surfaces of cylinder head and cover, refer to Tools

and Aids for approved sealants. Always use fresh

sealant. Using outdated sealant could result in

leakage. With O-ring type covers, make sure sealing

surfaces are clean.

2. Make sure there are no nicks or burrs on sealing

surfaces.

3. For covers requiring RTV sealant, apply a 1.5 mm

(1/16 in.) bead to sealing surface of both cylinder

heads, install a new cover gasket on each, then

apply a second bead of sealant on top surface of

gaskets. For O-ring type covers, install a new O-ring

in groove of each cover. Do not use gaskets or RTV

sealant.

4. Locate cover with oil fi ll neck on same side as

removed and install lifting strap in original position.

With O-ring type covers, position cover on cylinder

head. If loose spacers were used, insert a spacer in

each screw hole. On both types, install four screws

in each cover and fi nger tighten.

5. Torque valve cover fasteners to proper specifi cation

using sequence shown.

Torque Specifi cations-Covers

Gasket/RTV 3.4 N·m (30 in. lb.)

Black O-ring

w/shoulder screws

w/screws and spacers

5.6 N·m (50 in. lb.)

9.9 N·m (88 in. lb.)

Yellow or Brown O-ring

w/integral spacers 9.0 N·m (80 in. lb.)

Install Air Cleaner Assembly

Low-Profi le Air Cleaner

NOTE: Route fuel line in contour to avoid restriction.

1. Attach rubber breather hose to breather cover.

Connect fuel inlet line to carburetor and secure with

a clamp.

2. If equipped, carefully install evap hose fi tting into

bottom of air cleaner base.

3. Position a new gasket and air cleaner base while

carefully pulling loose end of rubber breather hose

through base until properly seated (collars sealed

against each side of base).

4. Secure air cleaner base and bracket using screws.

Position bracket with hole toward breather hose. Be

careful not to drop screws into carburetor. If a rear

air cleaner bracket is used, install two M5 screws

through rear of base. Torque three M6 screws to

6.2-7.3 N·m (55-65 in. lb.) and two rear M5 mounting

screws (when applicable) to 4.0 N·m (35 in. lb.).

5. Install breather hose in hole of bracket. If equipped,

install evap hose in other hole of bracket.

6. Install air cleaner components, refer to Air Cleaner/

Intake.

Heavy-Duty Air Cleaner

1. If equipped, place a new air cleaner base gasket on

carburetor and reinstall remote air cleaner adapter.

Install 2 screws and torque to 7.3 N·m (65 in. lb.).

Place a new adapter gasket on adapter. Make sure

holes in gasket are in proper location.

2. If equipped, route evap line through strap on bottom

of air cleaner support bracket and position air

cleaner and bracket assembly on engine.

3. Align air cleaner mounting bracket with valve cover

mounting holes and start screws. On two-barrel

carburetor models start two mounting screws into

top of intake manifold.

4. Check alignment of bracket and torque valve cover

screws as prescribed in Install Valve Covers. Torque

upper mounting screws into manifold (two-barrel

models only) to 9.9 N·m (88 in. lb.).

5. Secure adapter elbow to remote adapter with 2

screws. Torque screws to 7.3 N·m (65 in. lb.).

6. Connect air cleaner hose to adapter elbow or

adapter on carburetor and secure with a clamp.

Install and tighten hood onto air cleaner inlet.

7. Reconnect evap line to fi tting in adapter. Connect

breather hose to breather cover and fi tting on

adapter/elbow; position clamps to secure.

Reassembly

122 24 690 06 Rev. PKohlerEngines.com

Loading...

Loading...