Section 9

Inspection and Reconditioning

9.4

2. Use an inside micrometer, telescoping gauge, or

bore gauge and measure the cylinder bore. Take

the measurement approximately 63.5 mm (2.5 in.)

below the top of the bore and perpendicular to

the piston pin.

3. Piston-to-bore clearance is the diff erence between

the bore diameter and the piston diameter (Step 2

minus Step 1).

Flywheel

Inspection

Inspect the fl ywheel for cracks and the fl ywheel

keyway for damage. Replace the fl ywheel if it is

cracked. Replace the fl ywheel, the cranksha , and

the key if fl ywheel key is sheared or the keyway is

damaged.

Inspect the ring gear for cracks or damage. Kohler

does not provide the ring gear as a serviceable part.

Replace the fl ywheel if the ring gear is damaged.

Cylinder Head and Valves

Inspection and Service

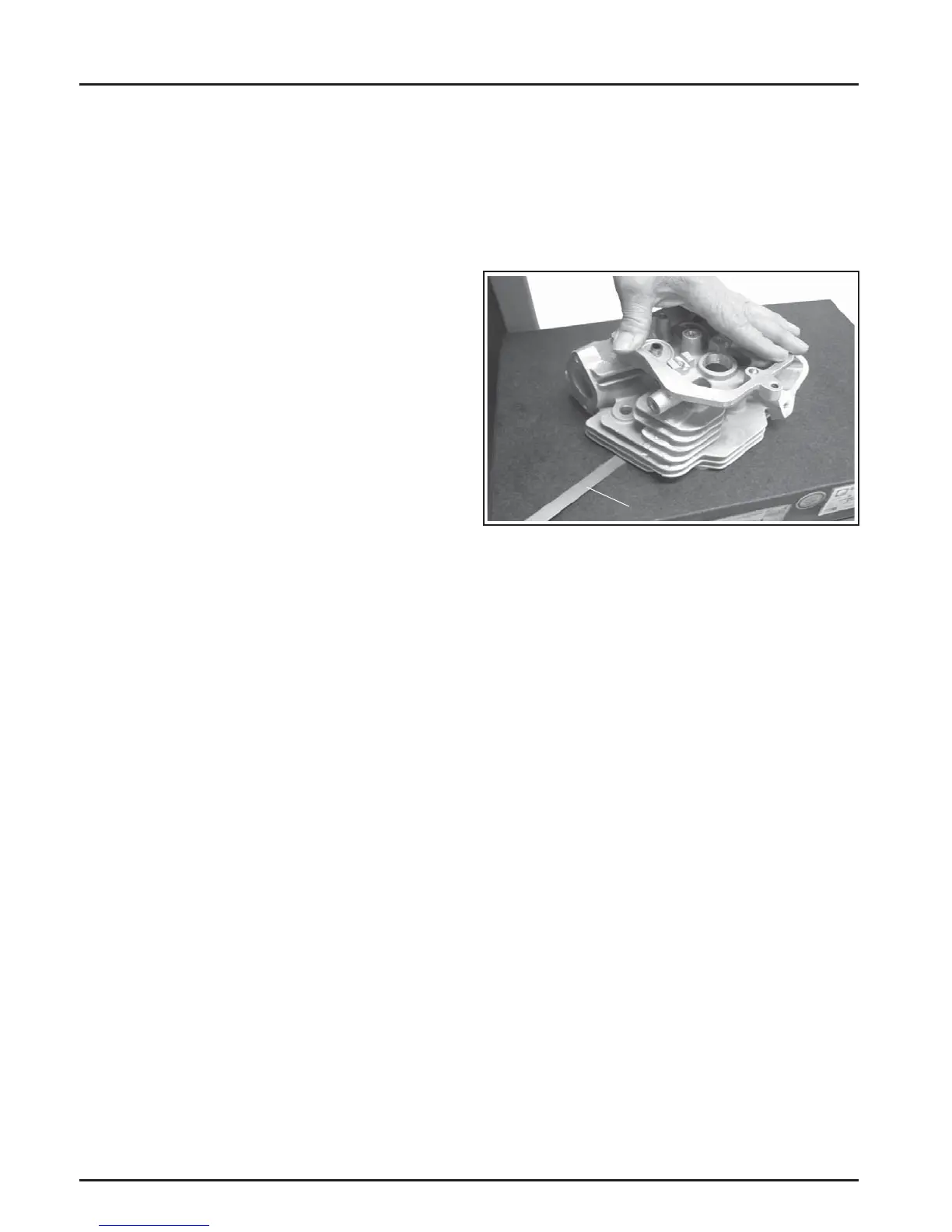

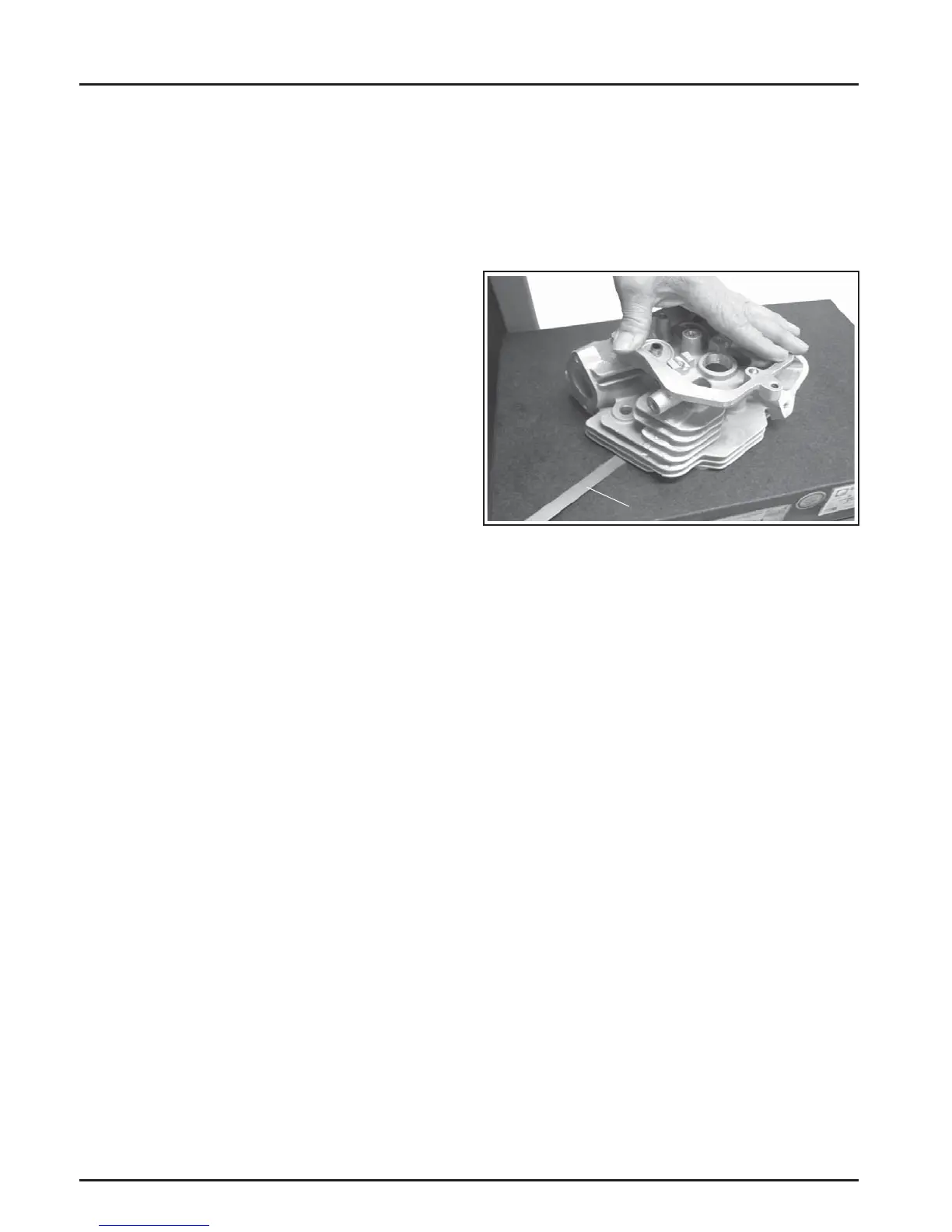

A er cleaning, check the fl atness of the cylinder head

and the corresponding top surface of the crankcase,

using a surface plate or piece of glass and feeler gauge

as shown in Figure 9-5. The maximum allowable out

of fl atness is 0.076 mm (0.003 in.).

Feeler Gauge

Figure 9-5. Checking Cylinder Head Flatness.

Carefully inspect the valve mechanism parts. Inspect

the valve springs and related hardware for excessive

wear or distortion. Check the valves and valve seat

area or inserts for evidence of deep pi ing, cracks,

or distortion. Check clearance of the valve stems

in the guides. See Figure 9-6 for valve details and

specifi cations.

Loading...

Loading...