11.14

Section 11

Reassembly

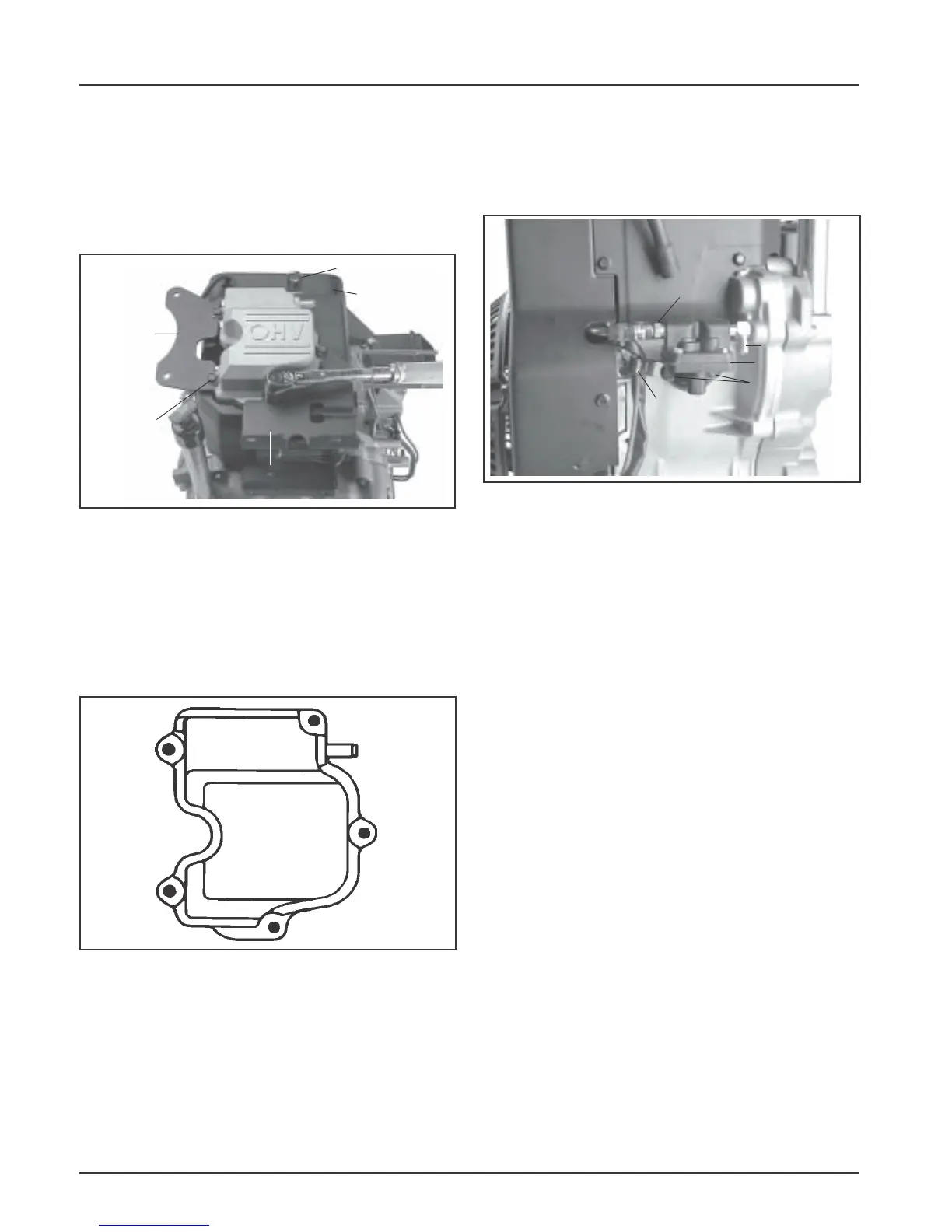

Figure 11-44. Installing Valve Cover. (Die Cast/

Aluminum Cover Shown).

4. Torque the screws in the sequence shown in

Figure 11-45, as follows:

Into new hole 10.7 N·m (95 in. lb.).

Into used hole 7.3 N·m (65 in. lb.).

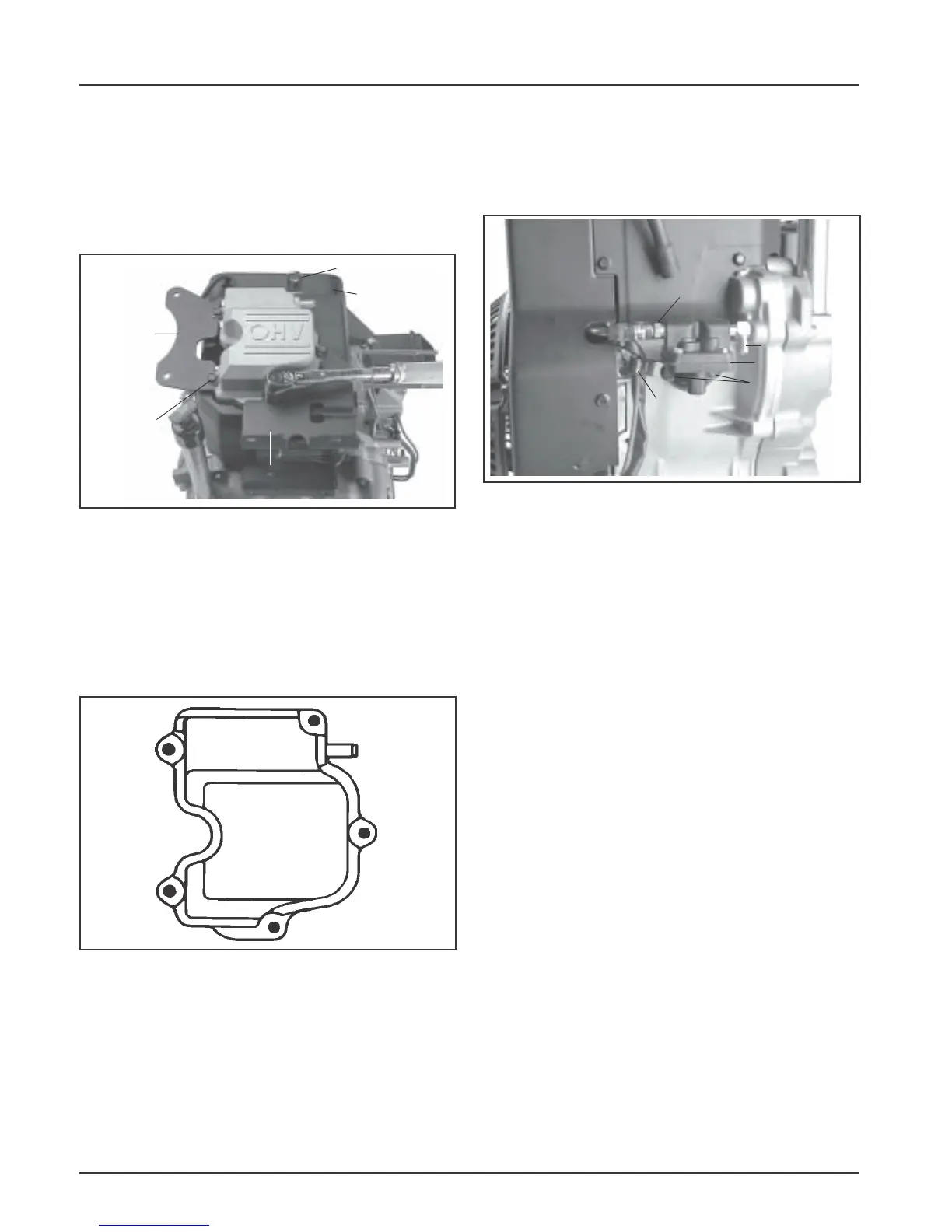

Install Fuel Pump

1. Install the rubber line and two hose clamps to

the fuel pump end of the metal fuel line. Secure

the rubber fuel line to the metal fuel line with one

of the clamps. See Figure 11-46.

Figure 11-46. Installing Fuel Pump.

2. Install the gasket, fuel pump, and two hex flange

screws. Attach the wire harness clamp (if used)

onto the closest screw. Torque the screws as

follows:

Into new hole 9.0 N·m (80 in. lb.).

Into used hole 4.2-5.1 N·m (37-45 in. lb.).

3. Install the opposite end of the rubber line to the

outlet fitting of the fuel pump. Secure the fuel

line to the outlet fitting with the other hose

clamp.

Install Electric Starter

Electric Starter (Inertia Drive or Solenoid Shift)

1. Install the studs for starter into the crankcase (if

applicable and removed previously). The longer

set of threads must be out.

2. Install starter with spacer and ground lead (if

used) on the studs, or install starter using the

mounting bolts as originally equipped. See Figure

11-47.

Clamp

Outlet

Fuel Pump

Hex Flange

Screws

Inlet

1

2

3

4

5

Hex

Flange

Head

Screws

Lift Bracket

Cylinder

Head Baffle

Fuel Tank

Bracket

3. Install the valve cover, any attached mounting

brackets (muffler, fuel tank, and/or lift*) along

with any loose spacers (stamped steel cover) as

originally attached onto the cylinder head. Secure

with the five hex flange screws. See Figure 11-44.

*Lifting bracket must be toward the flywheel.

Figure 11-45. Valve Cover Torque Sequence.

Muffler Bracket

Loading...

Loading...