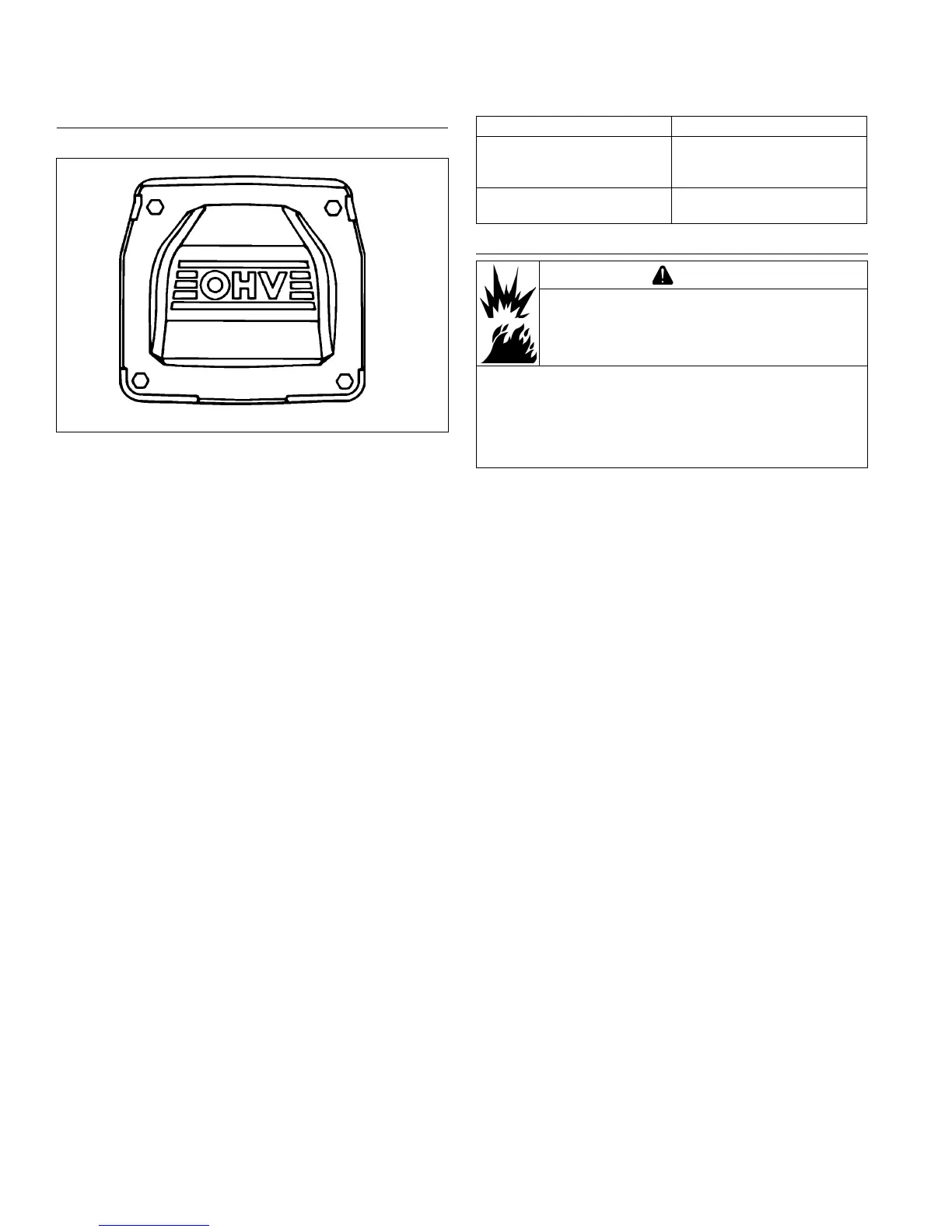

Install Valve Covers

Torque Sequence

24

1

3

NOTE: Do not scrape old RTV sealant (if used) off

sealing surface of cylinder head as this could

cause damage and result in leaks. Use of gasket

remover solvent (paint remover) is

recommended.

Three valve cover designs have been used. First type

used a gasket and RTV sealant between cover and

sealing surface of cylinder head. Second type had a

black O-ring installed in a groove on underside of cover

and may have metal spacers in bolt holes. Latest design

uses a yellow or brown O-ring, with bolt hole spacers

molded in place. Tightening torque differs between

gasket and O-ring style covers. Kits are available for

converting to latest O-ring type covers. Differences are

pointed out in following installation steps.

1. If using gasket or sealant type cover, prepare sealing

surfaces of cylinder head and cover, refer to Tools

and Aids for approved sealants. Always use fresh

sealant. Using outdated sealant could result in

leakage. With O-ring type covers, make sure sealing

surfaces are clean.

2. Make sure there are no nicks or burrs on sealing

surfaces.

3. For covers requiring RTV sealant, apply a 1.5 mm

(1/16 in.) bead to sealing surface of both cylinder

heads, install a new cover gasket on each, then

apply a second bead of sealant on top surface of

gaskets. For O-ring type covers, install a new O-ring

in groove of each cover. Do not use gaskets or RTV

sealant.

4. Position covers on cylinder heads. Locate cover with

oil separator hole on cylinder 1. If loose spacers

were used, insert a spacer in each screw hole.

Install screws in each cover and nger tighten.

5. Torque valve cover fasteners to proper specication

using sequence shown, unless screws also attach

heavy-duty air cleaner main support bracket or other

components. Installation and torquing of screws will

be performed after these parts are installed.

Torque Specications-Covers

Gasket/RTV 3.4 N·m (30 in. lb.)

Black O-ring

w/shoulder screws

w/screws and spacers

5.6 N·m (50 in. lb.)

9.9 N·m (88 in. lb.)

Yellow or Brown O-ring

w/integral spacers 6.2 N·m (55 in. lb.)

Install Carburetor

WARNING

Explosive Fuel can cause res and severe

burns.

Do not ll fuel tank while engine is hot or

running.

Gasoline is extremely ammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or ames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

1. Install a new carburetor gasket. Make sure all holes

align and are open.

2. Install carburetor, throttle linkage, choke linkage, and

governor lever as an assembly. If a plastic intake

manifold is used and/or carburetor is equipped with

a fuel solenoid, reconnect ground and main leads.

Reassembly

84

24 690 07 Rev. HKohlerEngines.com

Loading...

Loading...