Carburetor Servicing

WARNING

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Before working on engine or equipment, disable

engine as follows: 1) Disconnect spark plug lead(s). 2)

Disconnect negative (–) battery cable from battery.

NOTE: Main and slow jets are fi xed and size specifi c

and can be removed if required. Fixed jets for

high altitudes are available.

NOTE: Keep solvent away from plastic or rubber parts if

non-compatible or damage may occur.

● Inspect carburetor body for cracks, holes, and other

wear or damage.

● Inspect fl oat for cracks, holes, and missing or

damaged fl oat tabs. Check fl oat hinge and shaft for

wear or damage.

● Inspect fuel inlet needle and seat for wear or damage.

● Inspect spring loaded choke plate to make sure it

moves freely on shaft.

Float Replacement/Overhaul/Choke Repair

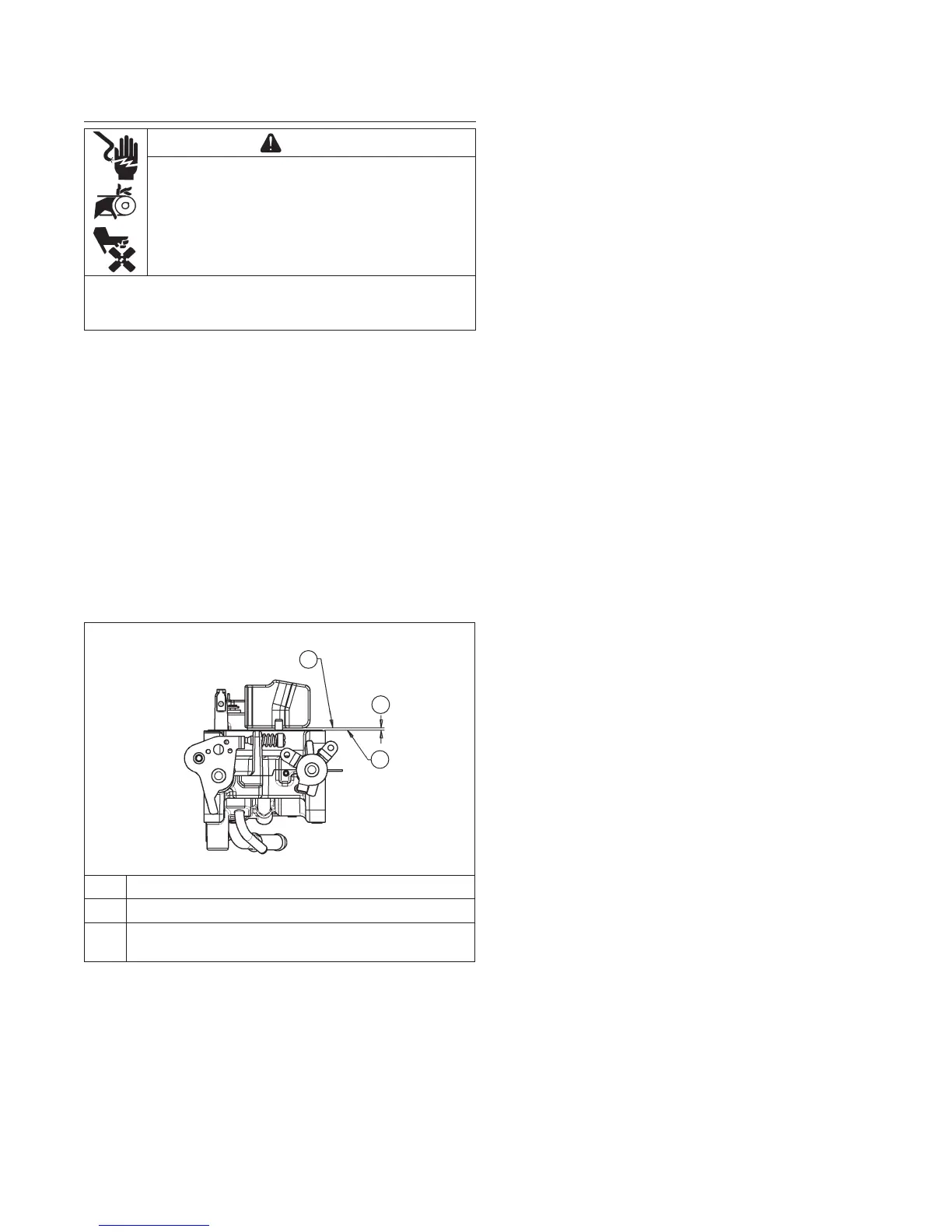

Float Setting

C

B

A

A Top of Float Body (Carburetor Body Inverted)

B Top of Gasket Crush Ribs

C

1.6 mm (0.063 in.) +/- 0.5 mm (0.02 in.) Float

Setting

NOTE: Inlet needle center pin is spring loaded. Make

sure fl oat rests against fuel inlet needle without

depressing center pin.

If symptoms described in Troubleshooting-Carburetor

Related Causes indicate fl oat level problems, remove

carburetor from engine to check and/or replace fl oat.

Use a fl oat kit to replace fl oat, pin, fl oat valve.

1. Perform removal procedures for appropriate air

cleaner and carburetor outlined in Disassembly.

2. Clean exterior surfaces of dirt or foreign material

before disassembling carburetor. Disconnect

accelerator pump vacuum hose from bottom of bowl.

Remove screws and carefully separate fuel bowl

from carburetor. Transfer any remaining fuel into an

approved container. Discard bowl screws and

gasket; save other parts.

3. Remove fl oat pin, lift out fl oat and inlet needle;

discard parts. Seat for inlet needle is not serviceable

and should not be removed.

4. Use a 1/4" open end wrench and carefully remove

nozzle tubes from bowl. Note and mark jets by

location for proper reassembly. Main jets and main

nozzles may be size/side specifi c. Main jets are

pressed into bottom of main nozzle tubes and are

not serviced separately. Slow jets are located to

outside of nozzle tubes and are removed with a

narrow, straight blade screwdriver. Save parts for

cleaning and reuse.

5. Remove accelerator pump cover screws from

bottom of bowl while holding pump cover in place.

Accelerator pump spring will be pushing against

cover as it is directly under it. Remove and discard

spring and diaphragm. Solenoid can also be

removed using a 1/2" wrench and gasket discarded.

6. Carburetor is now disassembled for appropriate

cleaning and installation of parts in overhaul kit.

Further disassembly is not necessary. Throttle shaft

assembly, fuel inlet seat, idle fuel adjustment screws

are non-serviceable items and should not be

removed. Choke shaft assembly is serviceable,

however it should not be removed unless a choke

repair kit will be installed.

To install choke repair kit go to step 7, otherwise go

to step 14.

7. Clean areas around choke lever/shaft assembly and

self-relieving choke mechanism thoroughly.

8. Note position of spring hooks and choke plate for

correct reassembly later. Remove screws attaching

choke plate to choke shaft. Pull shaft out of

carburetor body, note preload of spring and discard

removed parts.

9. Clean I.D. of both choke shaft bores as required.

10. Install new spring, plastic dust seal cover, and dust

seal on shaft.

11. Slide choke shaft assembly into carburetor,

connecting spring hooks to levers. Before seating

choke shaft completely, lever needs to be rotated

clockwise slightly to get past stop. This preloads

choke plate for proper starting function.

12. Position and reinstall choke plate to fl at side of

choke shaft. Start screws. Close choke and check

plate alignment within carburetor throat, then tighten

screws securely. Do not overtighten.

13. Check for proper operation and free movement of

parts.

Fuel System

2524 690 34 Rev. D KohlerEngines.com

Loading...

Loading...