5.13

Section 5

EFI Fuel System

5

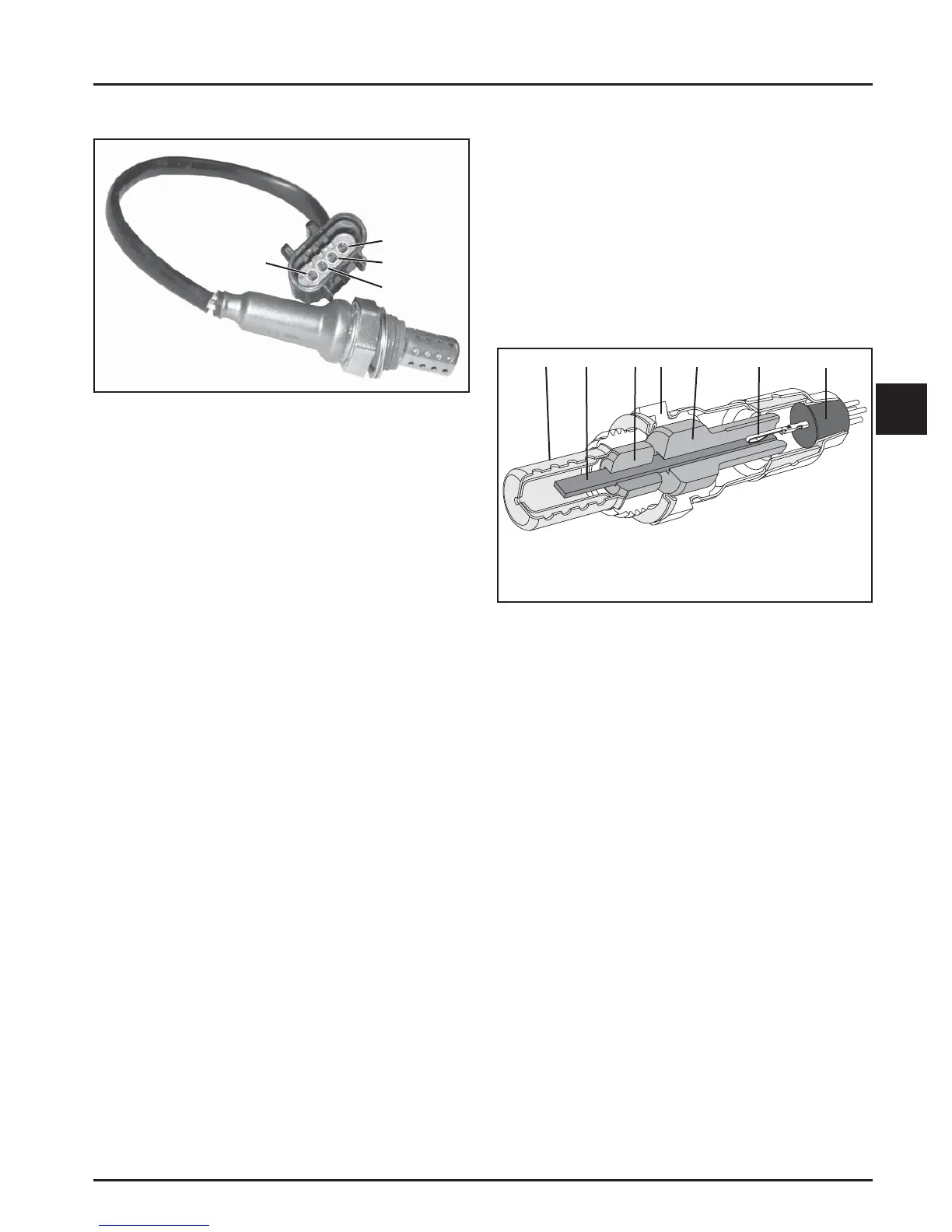

Figure 5-9. Oxygen Sensor.

General

The oxygen sensor functions like a small ba ery,

generating a voltage signal to the ECU based upon the

diff erence in oxygen content between the exhaust gas

and the ambient air.

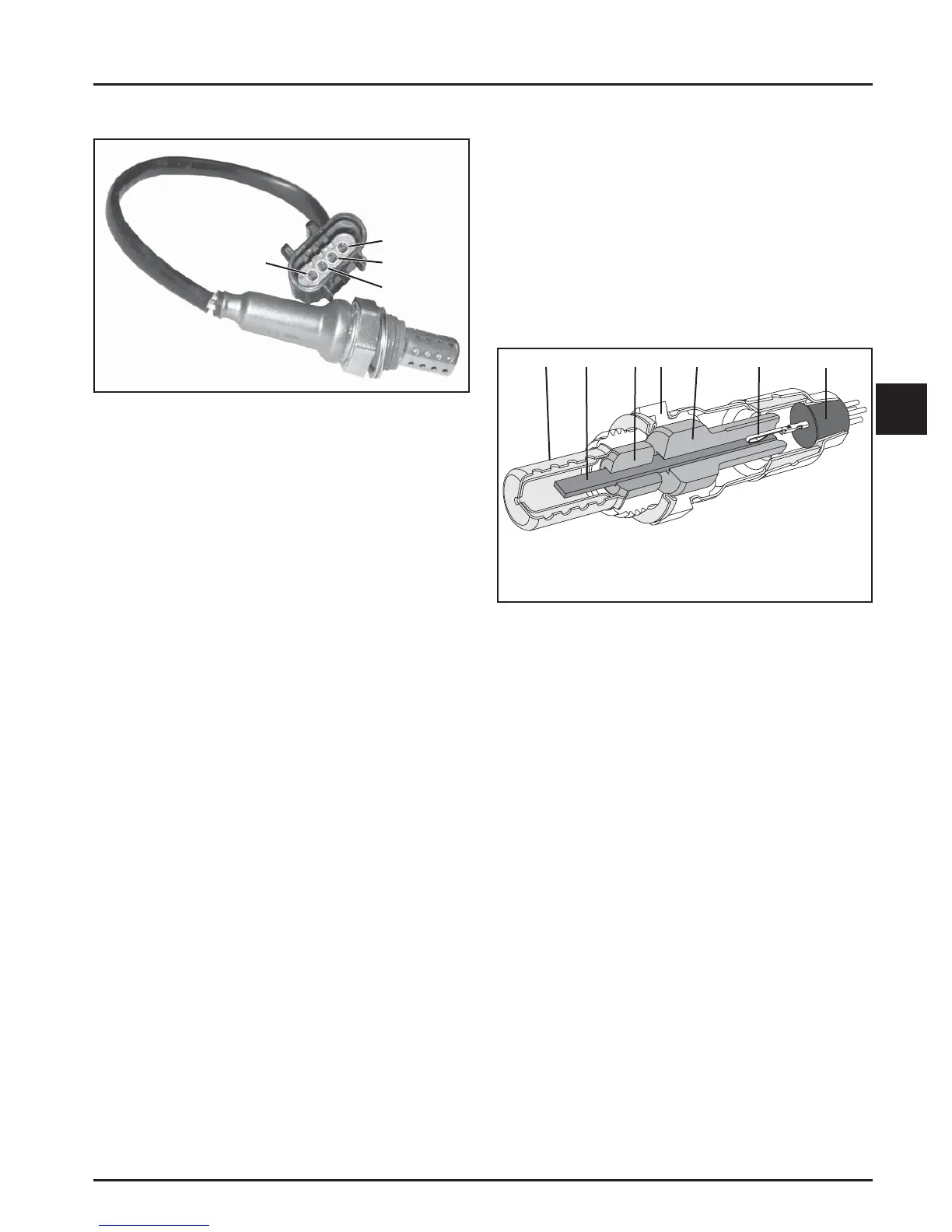

The tip of the sensor, protruding into the exhaust gas,

is hollow (see cutaway Figure 5-10). The outer portion

of the tip is surrounded by the exhaust gas, with the

inner portion exposed to the ambient air. When the

oxygen concentration on one side of the tip is diff erent

than that of the other side, a voltage signal up to 1.0

volt is generated and sent to the ECU. The voltage

signal tells the ECU if the engine is straying from

the ideal fuel mixture, and the ECU then adjusts the

injector pulse accordingly.

The oxygen sensor functions a er being heated to a

minimum of 400°C (752°F). A heater inside the sensor

heats the electrode to the optimum temperature in

about 10 seconds. The oxygen sensor receives the

ground through the wire, eliminating the need for

proper grounding through the muffl er. If problems

indicate a bad oxygen sensor, check all connections

and wire harness. The oxygen sensor can also be

contaminated by leaded fuel, certain RTV and/or other

silicone compounds, fuel injector cleaners, etc. Use

only those products indicated as O

2

Sensor Safe.

12 345 6

7

1. Protection Shield

2. Planar Element and Heater

3. Lower Insulator

4. Stainless Steel Housing

5. Upper Insulator

6. Terminal Connection to

Element

7. High Temp Water Seal

Pin D

Pin C

Pin B

Pin A

Oxygen Sensor

Service

The temperature must be controlled very accurately

and gas constituents measured to a high degree of

accuracy for absolute sensor measurements. Since

this requires laboratory equipment, it is not possible

to distinguish a marginally in specifi cation sensor

from a marginally out of specifi cation sensor with

simple fi eld diagnostic equipment. Furthermore, as

with most devices, intermi ent problems are diffi cult

to diagnose. Still, with a good understanding of the

system and the sensor, it is possible to diagnose many

sensor problems in the fi eld.

Figure 5-10. Cutaway of Oxygen Sensor.

Using diagnostic so ware connected to the ECU is a

useful technique for observing sensor performance.

However, the user must understand that such

so ware reads a signal generated by the ECU. If there

is an ECU or wiring problem, the readings could

be misinterpreted as a sensor problem. The digital

nature of the signal to the so ware means that it

is not reading the continuous output of the sensor.

A voltmeter can also be used as an eff ective tool in

diagnosing sensors. It is advisable to use an electronic

meter such as a digital voltmeter. Simple mechanical

meters may place a heavy electrical load on the sensor

and cause inaccurate readings. Since the resistance of

the sensor is highest at low temperatures, such meters

will cause the largest inaccuracies when the sensor is

in a cool exhaust.

Loading...

Loading...