7.8

Section 7

Electrical System and Components

Solenoid Shift Electric Starters

Operation – Solenoid Shift Starter

When power is applied to the starter the electric

solenoid moves the drive pinion out onto the drive

sha and into mesh with the fl ywheel ring gear. When

the pinion reaches the end of the drive sha it rotates

the fl ywheel and cranks the engine.

When the engine starts and the start switch is released

the starter solenoid is deactivated, the drive lever

moves back, and the drive pinion moves out of mesh

with the ring gear into the retracted position.

Figure 7-8. Completed Delco-Remy Starter.

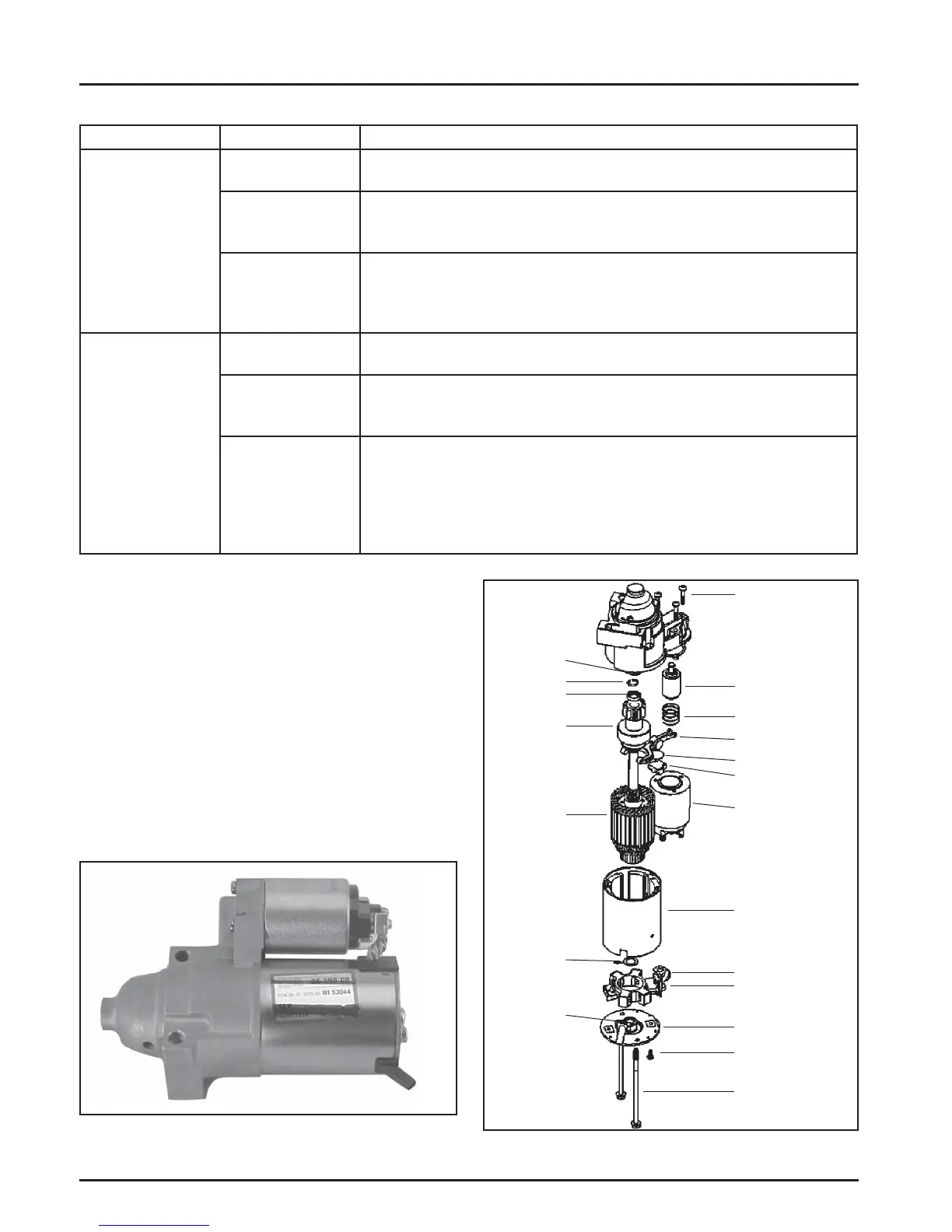

Figure 7-9. Delco-Remy Starter.

Screw

Plunger

Spring

Lever

Plate

Collar

Ring

Stop

Drive

Armature

Plug

Solenoid

Frame & Field

Brush Holder

Washer

Tube

Nut

CE Frame

Screw

Bolt

Problem Possible Fault Correction

Starter Does Not

Energize

Battery

1. Check the specifi c gravity of ba ery. If low, recharge or replace

ba ery as necessary.

Wiring

1. Clean corroded connections and tighten loose connections.

2. Replace wires in poor condition and with frayed or broken

insulation.

Starter Switch or

Solenoid

1. By-pass the switch or solenoid with a jumper wire. If starter

cranks normally, replace the faulty components. Solenoid Shi

Starters: Perform individual solenoid test procedure. See pages

7.16 and 7.17.

Starter Energizes

but Turns Slowly

Battery

1. Check the specifi c gravity of ba ery. If low, recharge or replace

ba ery as necessary.

Brushes

1. Check for excessively dirty or worn brushes and commutator.

Clean using a coarse cloth (not emery cloth).

2. Replace brushes if excessively or unevenly worn.

Transmission or

Engine

1. Make sure the clutch or transmission is disengaged or placed

in neutral. This is especially important on equipment with

hydrostatic drive. The transmission must be exactly in neutral to

prevent resistance which could keep the engine from starting.

2. Check for seized engine components such as the bearings,

connecting rod, and piston.

Troubleshooting Guide - Staring Diffi culties

Loading...

Loading...