10.7

Section 10

Reassembly

10

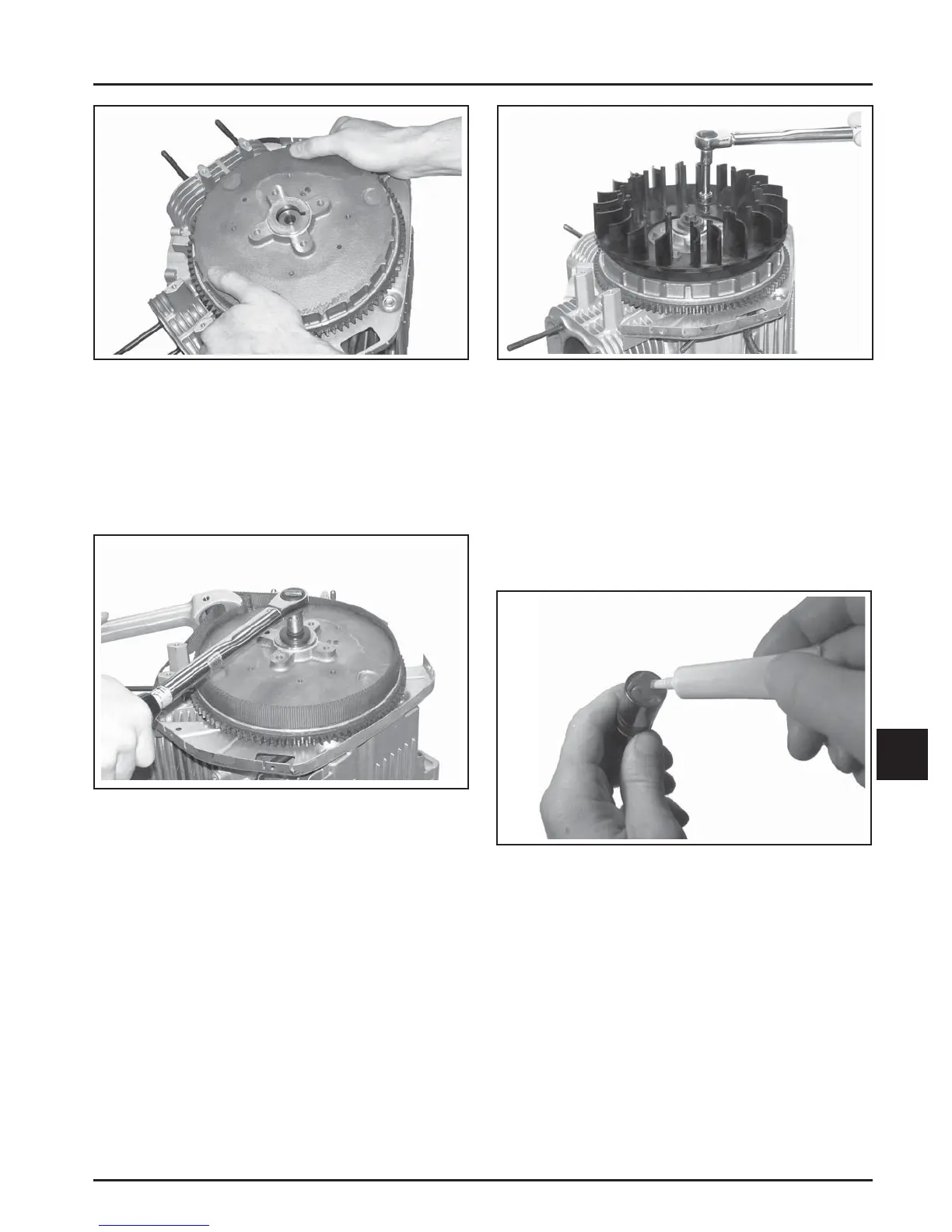

Figure 10-21. Carefully Align Keyway to Key.

3. Install the hex fl ange screw and washer.

4. Use a fl ywheel strap wrench or holding tool to

hold the fl ywheel. Torque the hex fl ange screw

securing the fl ywheel to the cranksha to

71.6 N·m (52.8 . lb.). See Figure 10-22.

Figure 10-22. Installing and Torquing Flywheel

Fastener.

Install Fan

1. Install the fan onto the fl ywheel using the four

hex fl ange screws (engines with plastic grass

screen). For engines with a metal grass screen,

leave it loosely assembled.

NOTE: Position the locating tabs on the back of the

fan into the locating holes of the fl ywheel. See

Figure 10-23.

2. Torque the screws to 9.9 N·m (88 in. lb.).

Figure 10-23. Installing Fan.

Install Cylinder Heads and Hydraulic

Lifters

1. See Servicing Hydraulic Li ers in Section 9 for

li er preparation (bleed down) procedures.

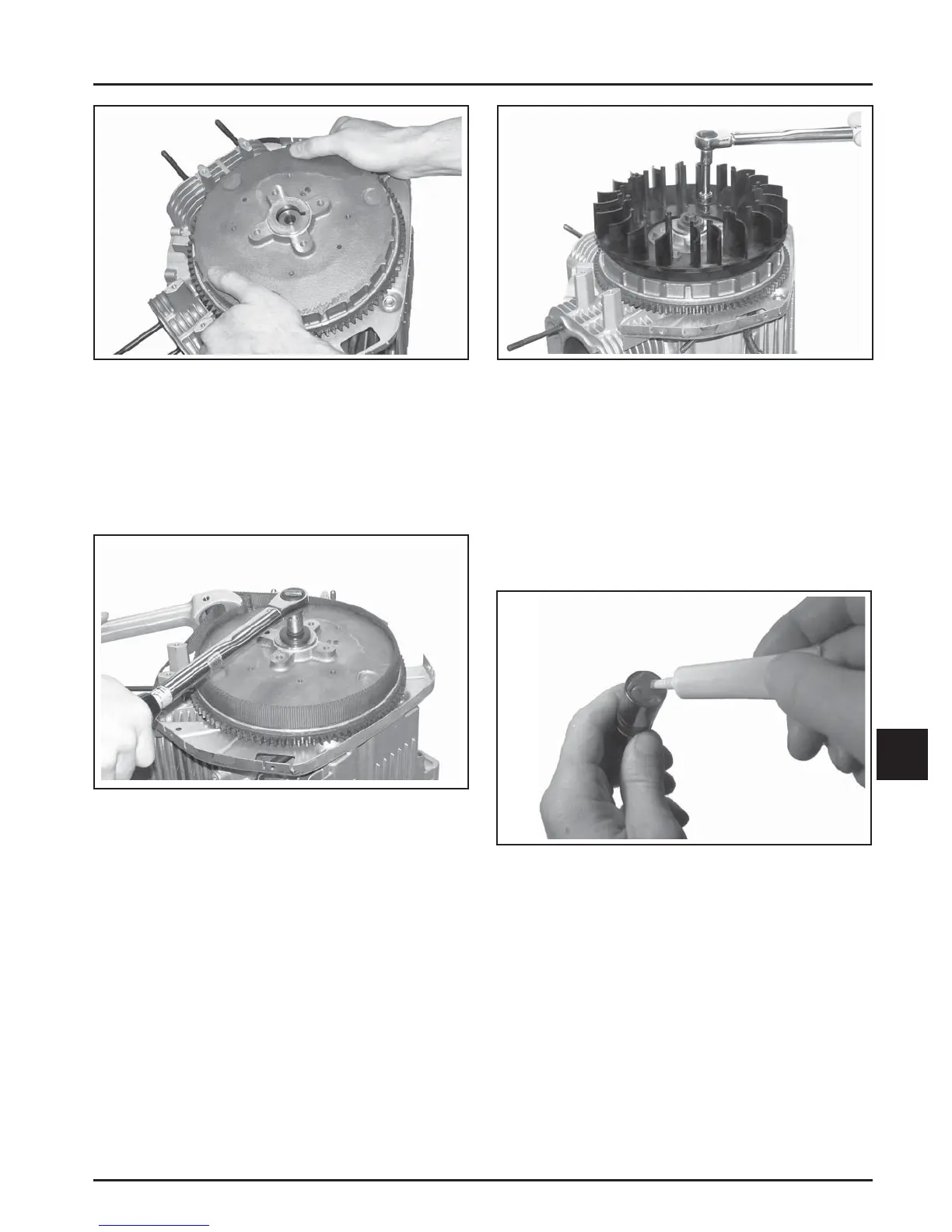

2. Apply camsha lubricant (see Section 2) to the

bo om surface of each li er. See Figure 10-24.

Lubricate the hydraulic li ers and the li er bores

in the crankcase with engine oil.

Figure 10-24. Applying Camshaft Lubricant to

Bottom of Lifters.

3. Note the mark or tag identifying the hydraulic

li ers as either intake or exhaust and cylinder 1

or cylinder 2. Install the hydraulic li ers into

their appropriate locations in the crankcase. Do

not use a magnet. See Figure 10-25.

Loading...

Loading...