9.5

Section 9

Inspection and Reconditioning

9

Valve Guides

ȱȱȱȱȱȱ¢ȱęǰȱȱȱ

not guide the valve in a straight line. This may result

in burned valve faces or seats, loss of compression,

and excessive oil consumption.

To check valve guide-to-valve stem clearance,

thoroughly clean the valve guide and, using a split-

ball gauge, measure the inside diameter. Then, using

an outside micrometer, measure the diameter of

the valve stem at several points on the stem where

it moves in the valve guide. Use the largest stem

diameter to calculate the clearance. If the intake

clearance exceeds 0.047 mm (.0018 in.) or the exhaust

clearance exceeds 0.082 mm (.0032 in.), determine

whether the valve stem or guide is responsible for the

excessive clearance.

Maximum (I.D.) wear on the intake valve guide is

5.512 mm (0.2170 in.), while 5.512 mm (0.2170 in.)

is the maximum allowed on the exhaust guide. The

guides are not removable. If the guides are within

limits but the valve stems are worn beyond limits,

replace the valves.

Valve Seat Inserts

Hardened steel alloy intake and exhaust valve

ȱȱȱȱęĴȱȱȱ¢ȱǯȱ

The inserts are not replaceable, but they can be

ȱȱȱȱ¢ȱĴȱȱǯȱȱ

the seats are cracked or badly warped, the cylinder

head should be replaced.

ȱȱȱȱȱȱȱ

ȱȱȱȱȱȱĴȱȱ

ǯȱȱ¢ȱĴȱȱȱȱȱşȬŘǯȱȱęȱ

ȱȱȱȱȱȱşŖǚȱĴȱȱęȱȱ

the valve seat angle in Figure 9-1. With the proper 45°

valve face angle, and the valve seat cut properly (44.5°

as measured from center line when cut 90°) this would

result in the desired 0.5° (1.0° full cut) interference

angle where the maximum pressure occurs on the

valve face and seat.

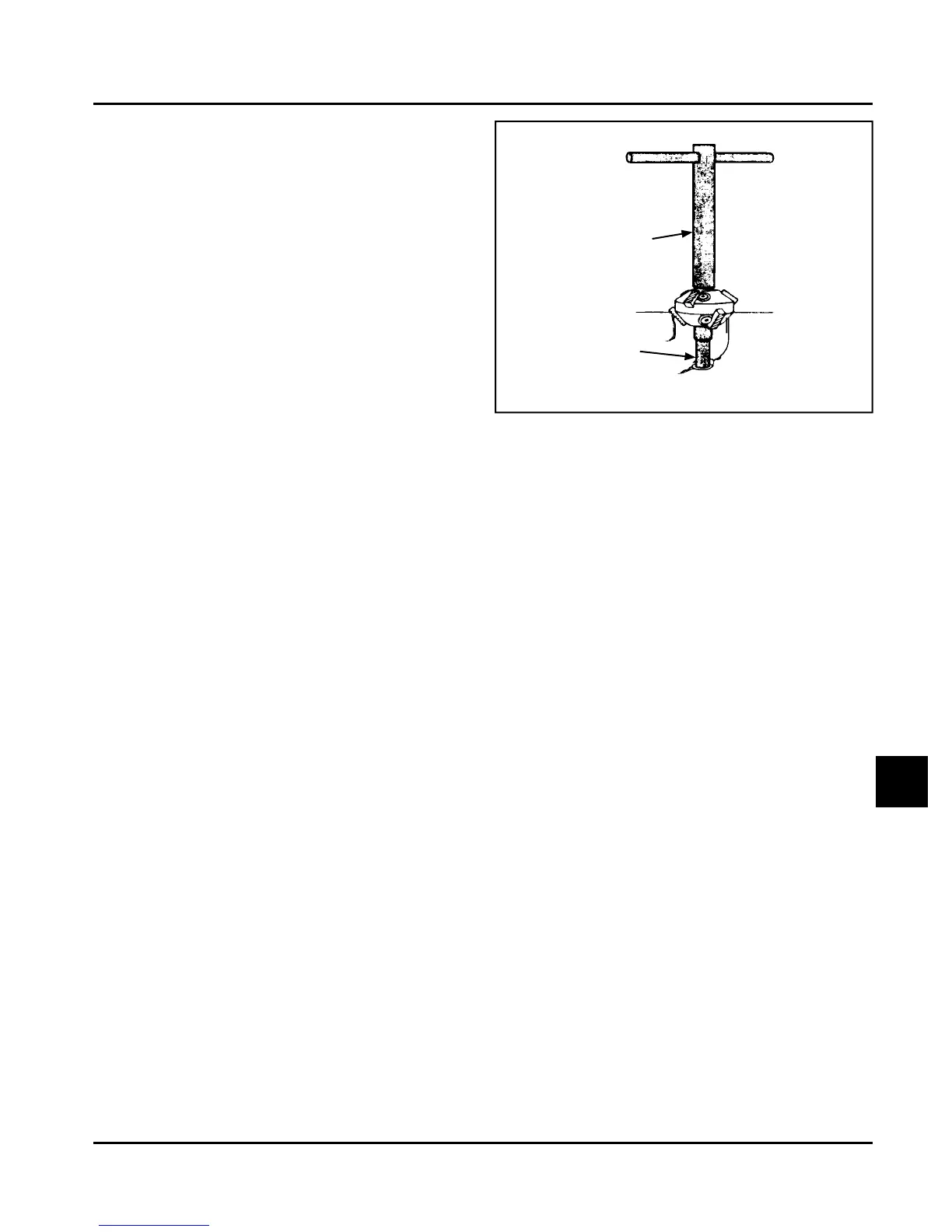

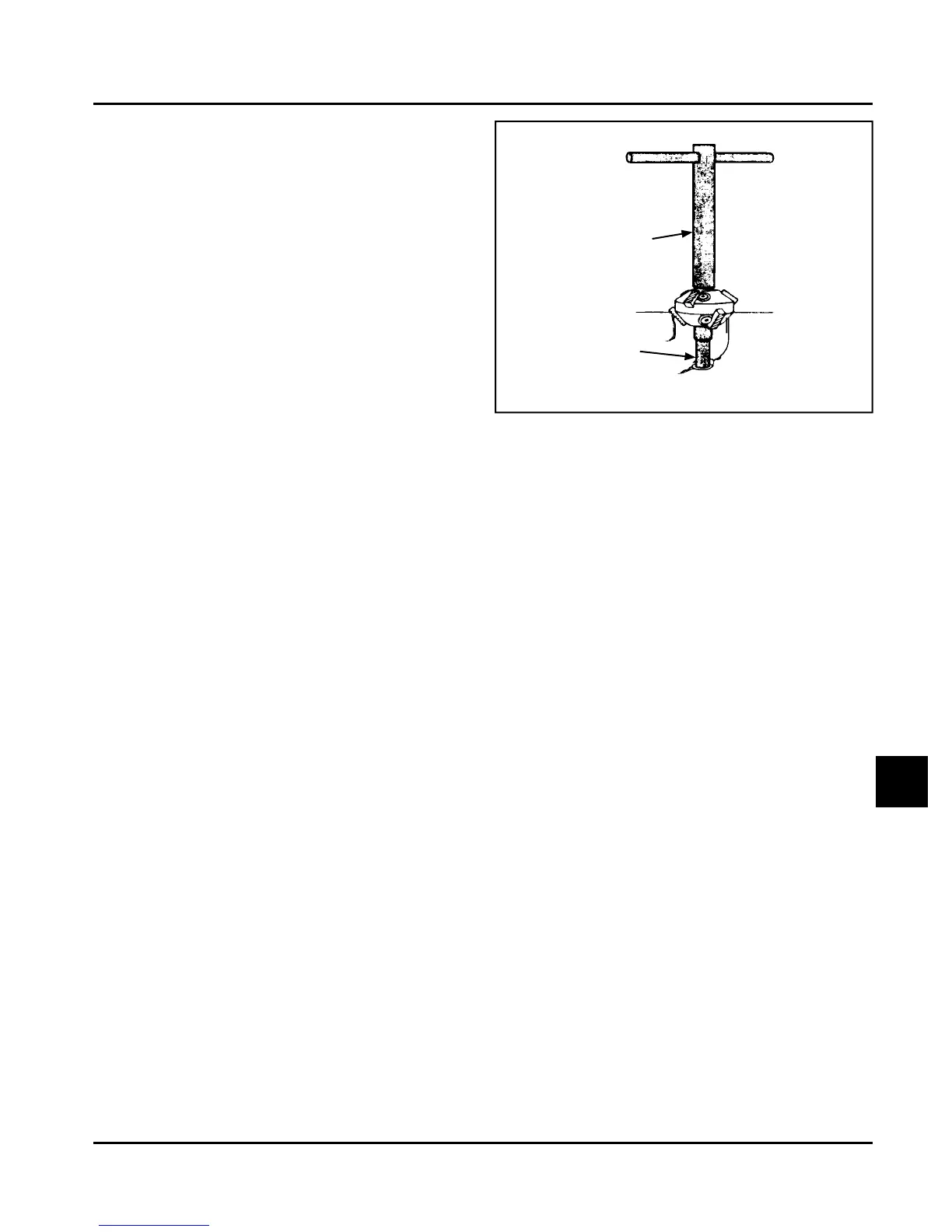

Valve Seat Cutter

Pilot

.001

Figure 9-2. Typical Valve Seat Cutter.

Lapping Valves

ȱȱȱȱȱȱȱǰȱȱ

provide a good seal. Use a hand valve grinder with

ȱȱȱęȱǯȱ¢ȱȱȱȱ

ȱęȱȱȱȱǰȱȱȱ

valve on seat with grinder. Continue grinding until

smooth surface is obtained on seat and on valve face.

Thoroughly clean cylinder head in soap and hot water

ȱȱȱȱȱȱǯȱĞȱ

drying cylinder head, apply a light coating of engine

oil to prevent rusting.

Loading...

Loading...