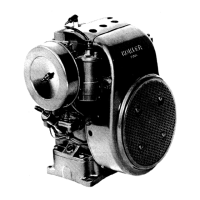

What to do if Kohler K181 Engine cranks but will not start?

- GGabrielle CowanAug 4, 2025

If your Kohler Engine cranks but won't start, it could be due to an empty fuel tank, a loose spark plug lead, loose wires intermittently shorting the ignition to ground, a closed fuel shutoff valve, a clogged fuel line, a disconnected spark plug lead, the keyswitch or kill switch being in the "off" position, an improperly adjusted carburetor, engine overheating, or incorrect valve-to-tappet clearance.