OWNER’S

MANUAL

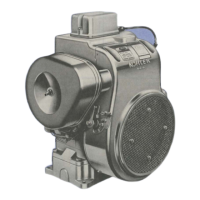

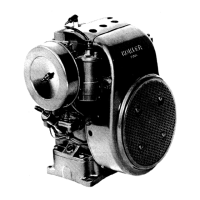

MODELS ’

K241/ K301

(10 hP)

(12 hp)

K321,& K341

(14 hp)

operating & maintenance

instructions

(16 hP)

Congratulations -

You have selected a fine four-cycle, single cylinder, air-cooled engine. Kohler designs long

life strength and on-the-job durability into each engine. . .

making a Kohler engine dependable.. .dependability

you can count on. Here are some reasons why:

0

Kohler engines are easy to service. All routine service areas (like the points, condenser, air cleaner, spark

plug, and carburetor) are easily and quickly accessible.

L

0

Parts subject to the most wear and tear (like the cylinders, crankshafts, and camshaft) are made from

precision formulated cast iron. Because the cast iron cylinders can be rebored, these engines can last even

longer.

0

Every Kohler engine is backed by a worldwide network of over 10,000 distributors and dealers. Service

support is just a phone call away. Call I-800-544-2444 (U.S. & Canada) for Sales & Service assistance.

To keep your engine in top operating condition, follow the maintenance procedures in this manual.