BREAKER

POINTS:

Points

are illld

er

th

e r ec

tangul

ar

cover on

th

e c

arbur

et

or

si

de

of

engi ne . Use

th

e follow

in

g

procedure t o adjust

br

e

aker

point

gap:

1.

Remove

br

eaker

poin

t cov

er.

2. Turn eng

in

e over illlt

il

br

eak

er

p

oints

are

full

open--measu

re

gap w

ith

fee

ler

gauge.

Op

enin

g

sh

ould

be .020". Adjust by

lo

osening gap adjust

in

g s

cr

ew

th

en ins

ert

screwdr

ive

r bl ade

in

adjust

in

g notch t o sh

if

t mo

veabl

e

plat

e

until

.020" op

enin

g i s

att

aine

d. R

eti

ghten gap ad-

just ing screw.

3.

Ga

p s

etting

ca~

vary (. 017 - .0 23). To ach

iev

e s

moo

thes t running see timing l i ght

in

stru

cti

ons

b

el

ow.

Alwa

ys r

epl

ace ba

dly

burned

or

pitt

ed

br

eak

er

po

int

s.

A ce

rtalll

am

ount of bui

ld

up or met

al

tran

sfer

o

ccur

s illlder normal opera

ti

ng c

onditi

ons; h

ow

ever,

if

thi

s oc

cur

s t oo

fre

qu

entl

y and beco

me

s exces sive ,

th

e condens

er

may be at

fault

.

Slightl

y

pitted

po

int

s can be dre

ssed

do

wn

wi t h a

point

file,

al though

th

i s should be done on

ly

as a tempor

ary

fi

x s

in

ce

point

s may t end t o

arc

more re

adil

y af

te

r f

ilin

g. Re-

pl

ace

point

s

at

fir

st

opportilllity af

te

r

filing.

If p

oint

s a

re

oxi d

ize

d, rub a p

ie

ce of coa

rse

cl

oth

be-

tween

the

surfaces.

Dirt

y

or

o

il

y poin

ts

can be

cl

eaned

with

a cloth

but

mak

e sure no p

article

s of

lint

a

re

l

eft

between

surfaces.

TIMI

N

G:

Engines

are

equipped

with

a

timin

g

sight

ho

le

in

eit her t he be

ari

ng

plat

e or

in

t he

bl

ow

er

housing.

Two

timlllg marks

ar

e st

am

ped on

the

fl

ywhe

el

--t

he T mark

ind

ic

at

es Top Dead Center

(TDC

) whi

le

t he S or

SP

ma

rk

llldicat

es t he Sp

ar

k or Spark Run p

oint

which i s 20

0

b

efore

TDC.

Tw

o methods can be used f

or

timing--th

e timing

li

ght

m

eth

od

is

th

e more

pre

ci

se way

of

a

chi

ev

ing

exa

ct

timing.

The

timin

g

li

ght

can be used

with

magn

eto

igniti

on sy

ste

ms

;

howe

v

er,

a st o

ra

ge b

att

ery

ma

y

have

to

be used p

er

timin

g

light

manufactur

er

I s

instructions.

MET

HOD

1 - S

TA

TIC

TIM

ING

: Re

mo

ve

br

eak

er

point

cov

er

and remove

spark

plug

le

ad t o

pr

ev

ent

illlintention

al

st ar

ti

ng. Rot

ate

eng

me

by hand

in

direction

of normal

rotation

(cloc

kw

ise

wh

en v

ie

we

d from blow

er

hou

sing

end) .

Point

s should

just

b

egin

to

break as

the

S mark app

ear

s in

th

e c

enter

of

th

e

timi

ng Si

ght

hol

e.

Continue r

ot

ating

eng

in

e

unt

i l po

in

ts

reach m

aximum

open

in

g. M

eas

ure gap wi th fe

el

er

gauge--gap shou

ld

be .0 20"

full

y open.

If

nece ss

ary,

loosen

point

gap adjustment s

cr

ew and

readjust

gap t o .020"

full

open.

Maximum

gap se

tt

ing

can va

ry

a few thousandths (.017 - . 023) to a

chiev

e smoothe

st

running. Sec

ur

e

ly

ti

ghten

adjust ing screw af

te

r timing.

METH

OD

2 - TIMING

LIQIT:

Several

diff

er

ent

types of timing

li

ghts

ar e

avail

able--follow

manu

fa

ctur

er's

llistru

ctions

for

type used. The fo

ll

ow

ing

timing procedure can be used wi

th

~

timin

g

li

ght

s:

A. R

emo

ve high

tension

lead

at

spark

plug--wrap one end

of

a shor t

pie

ce

of

fine

wi re around

spark

plug

t

erminal.

Reconnect

lead

to

t

erminal--fr

ee end

of

wir

e must p

rotrude

from under b

oot.

Ql

ote:

Step

A

for

timin

g

lights

with

alli

g

at

or

clips

- -s

ome

li

ght

s have sharp prongs on spa

rk

lead

--on

the

se sim-

pl

y push prong

thru

boot

until

it

con

ta

ct s

metal

connec

to

r

.)

B.

Co

nnect one

timin

g

light

lead

to

th

e

wir

e

th

at

has just been wrapped

ar

olIDd

spark

plug

t ermin

al.

C.

Conne

ct

second

timin

g

lignr-fe

ad t o h

ot

(

lIDg

rounded)

side

of

batt

ery--

see

timin

g

li

ght

ins

t ruct ions

for

bat

te

ry

s

ize

, wi

ring,

etC:--

D.

Conn

ect

third

timing

light

lead t o ground.

E.

Ro

t a

te

eng

in

e by hand

until

S mark v

is

ib

le

--cha

lk

S

lin

e for easy

re

ading.

F. S

ta

rt engine ,

run

at 1200 - 1800

RP

M,

aim

timin

g

li

ght

int

o s

ig

ht

hol

e--li

ght

should

fla

sh

just

as

S mark

is

centered

in

sight hol e

or

even

with

cent er mark on bear ing

pl

ate

or blow

er

housing.

G.

If timing

is

o

ff

--remove

breaker

p

oint

cover , loo

se

n gap adju

stin

g s

cr

ew, sh

ift

break

er

plat

e

until

S mark

is

exa

ctl

y c

ent

er

ed.

Reti

ght

en adjust lllg s

cre

w

bef

ore re

pl

acin

g

br

eaker

poi

nt cove

r.

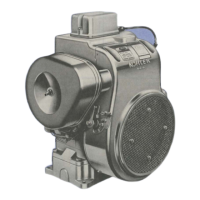

alternator

system

On e

le

ct ric st

art

models

the

15

amp

al t e

rna

to

r sy

st

em

provides

elect

ric

al

energy

to

charge t he b

atter

y.

A sol id

state

rectifi

er-regul

ator

is

mounted ex

te

rna

l

ly

on

th

e engi ne or on

th

e equipment powered by the

eng

ine

. The system a

lso

includ

es an

alternat

or-st

ator

and perm

anent

ma

gnet r i ng

ins

id

e

th

e f l

ywh

e

el.

These sys

te

ms

ar

e v

irtu

ally

s

ervice

fr ee

--the

on

ly

requ

ir

ed se

rv

ice

i s an oc

casiona

l check t o make su

re

th

at

all

el ectr ical connect

io

ns are

ti

ght

and

th

at

wir

es a

re

n

ot

fra

yed or c

ra

cked. Check

th

e prec

autions

t o

the

sys

te

m on your engine

to

a

void

dama

gin

g

chargin

g sys

te

m components .

P

RE

CA

lIT

IONS-

-15

AMP

SY

S

TEM

1. Bat

tery

polarit

y mus t be

cor

rec

t .

Nega

t

iv

e ground sy

st

em

s

ar

e used

with

Koh

le

r Engin

es.

2. Pre

vent

al t ernator l eads

(A

C) from touching

or

shor t ing. This could perman

entl

y damage

th

e

stator.

3. Disconnect l eads

at

r

ectifier--r

egul

ator

bef

ore

e

lec

tr

ic

w

elding

is

done on

equi

pm

ent

in

comm

on

gro

lID

d

with

eng

in

e .

4. Do

not

ope

ra

t e

for

any l en

gth

of

t~ne

wi thout a b

att

e

ry

in

th

e sys

te

m.

7

Loading...

Loading...