cooling system service

Che

ck

air

intake

scr

een b

efor

e each st art -up and

make

sure

it

is

clean and unobstructed.

If

grass

clipp

ings, leaves,

dirt

etc.

start

building

up on intake

screen

while

operatin

g, st op engine and

clear

to prevent ov

erheating

. Cooling

air

is

drawn

into

the

blower hou

sing

by

fins

on

the

flywhe

el

and

is

circul

ated

past

coolin

g

fins

on block and heads and i s then

dis

charged toward

th

e

pow

er

t

ake-off

end of

the engine . Do n

ot

ope

rat

e

with

missing cool ing shrouds as

th

ese

dir

e

ct

coolin

g

air--r

emoval would re-

sul t

in

improper

air

circulation

and po

ssibl

e engine

dama

ge due to overhe

ating.

Clean

external

surfaces

of

your engine occa

sionally

as acc

um

ul at ion of

dust,

oil

can

contribute

to improper cool ing .

•

••

•

Ignition system service

Eng

in

e

misfire

or

generally

poor

operation

is

oft

en caused by spark

plu

gs

in

poor

condition

or

with

incorre

ct

spark gap s

etting.

Always

clean

area

ar

ound spark plugs

before

r

emo

ving to prev

ent

dirt

from

getting

into

engine.

Carefull

y n

ote

spark

plu

g condi t ion as

this

is

often a good

indicator

of t he

igni

-

tion

tr

ouble. Plugs

fail

for

va

riou

s

reas

ons. The porc

elain

insul

ator

may c

ra

ck or

become

coated

with

oi l , carbon or

other

depos

it

s.

This can

ca

use

the

hi gh

volta

ge

ignition

impulse to pass from

the

center

el

e

ctrod

e t o ground without jumping

the

spark gap.

As

an engine

operat

es,

the

ele

c

trodes

are

gradually

burned or worn away. In time,

the

gap bec

omes

so wide

that

the av

ailabl

e

ignition

vo

lta

ge cannot

jump

the gap and

th

e engine misse

s.

Oper

ati

on i s

al

so grea

tl

y

aff

e

cted

by

breaker

point

condi

tion

and

ad

j

l~

tme

n

t

of point gap.

If

point

s

are burned or badly o

xidiz

ed, l i t t

le

or no current

will

pass and as a resul t the eng

in

e

ma

y not op

erate

at

all,

or

if

it

does run,

it

is

lik

el

y

to

miss

particul

arly

at

full

thr

ottle.

SP

ARK

PLUGS:

Every 100 hours

remove

plugs,

check c

ondition

and

reset

gap or replace plug

if

needed.

Go

od o

peratin

g

conditi

ons

are

indicat

ed

if

plug has

li

ght

coat ing

of

gray or tan de

posit.

A dead whit

e,

bli

ster

ed coa

ti

ng could

indicat

e ov

erheating.

A

bl

ack (carbon)

coatin

g may indic

ate

an "overricW'

fuel

mixture caused by clogged air c

le

aner or improp

er

carburetor adjustment. Do not sandb

la

st , wire brush,

sc

ra

pe or

oth

erwise s

ervice

plug

in

poor condi t ion- -best

re

sult

s

ar

e obtained wi th n

ew

plug.

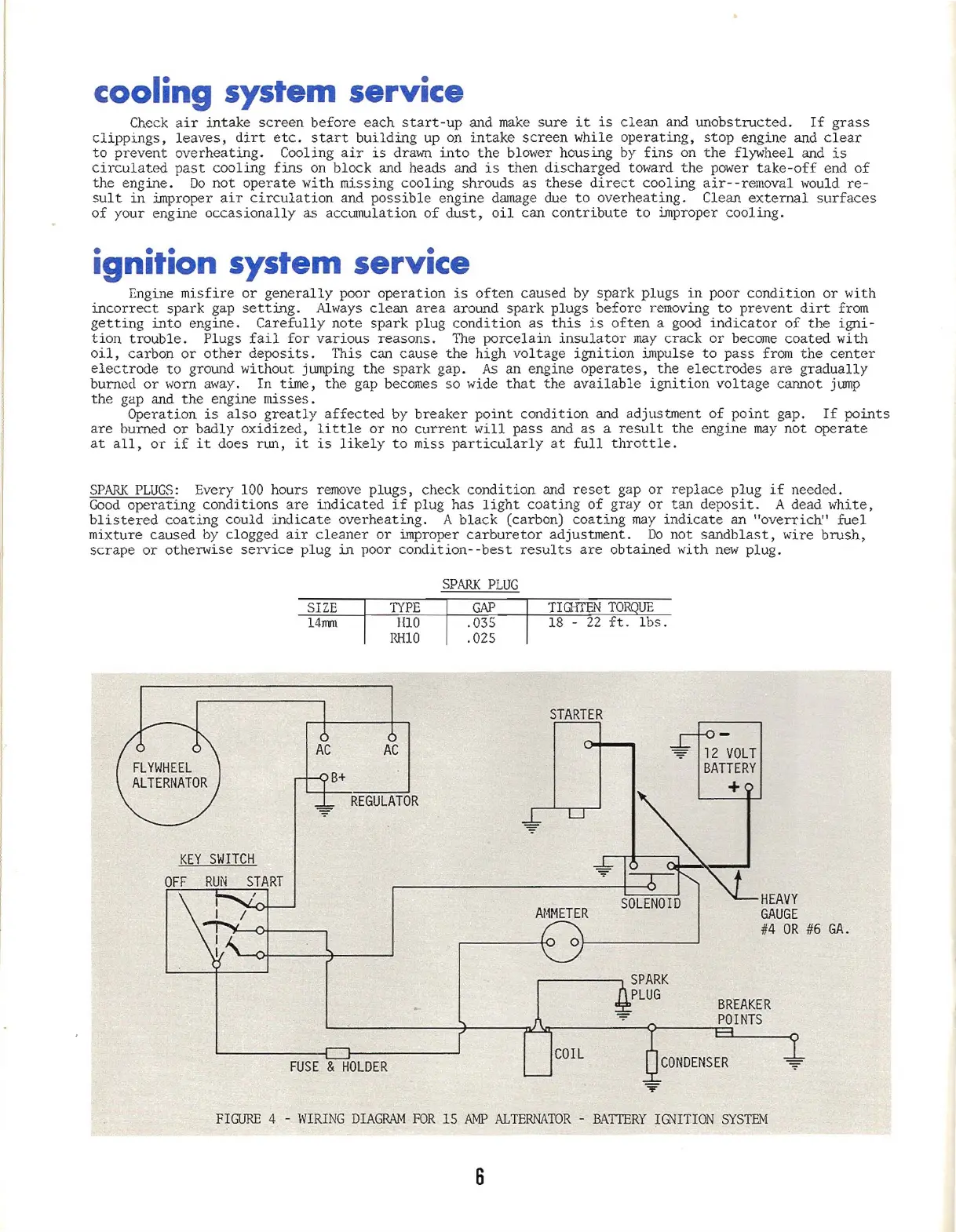

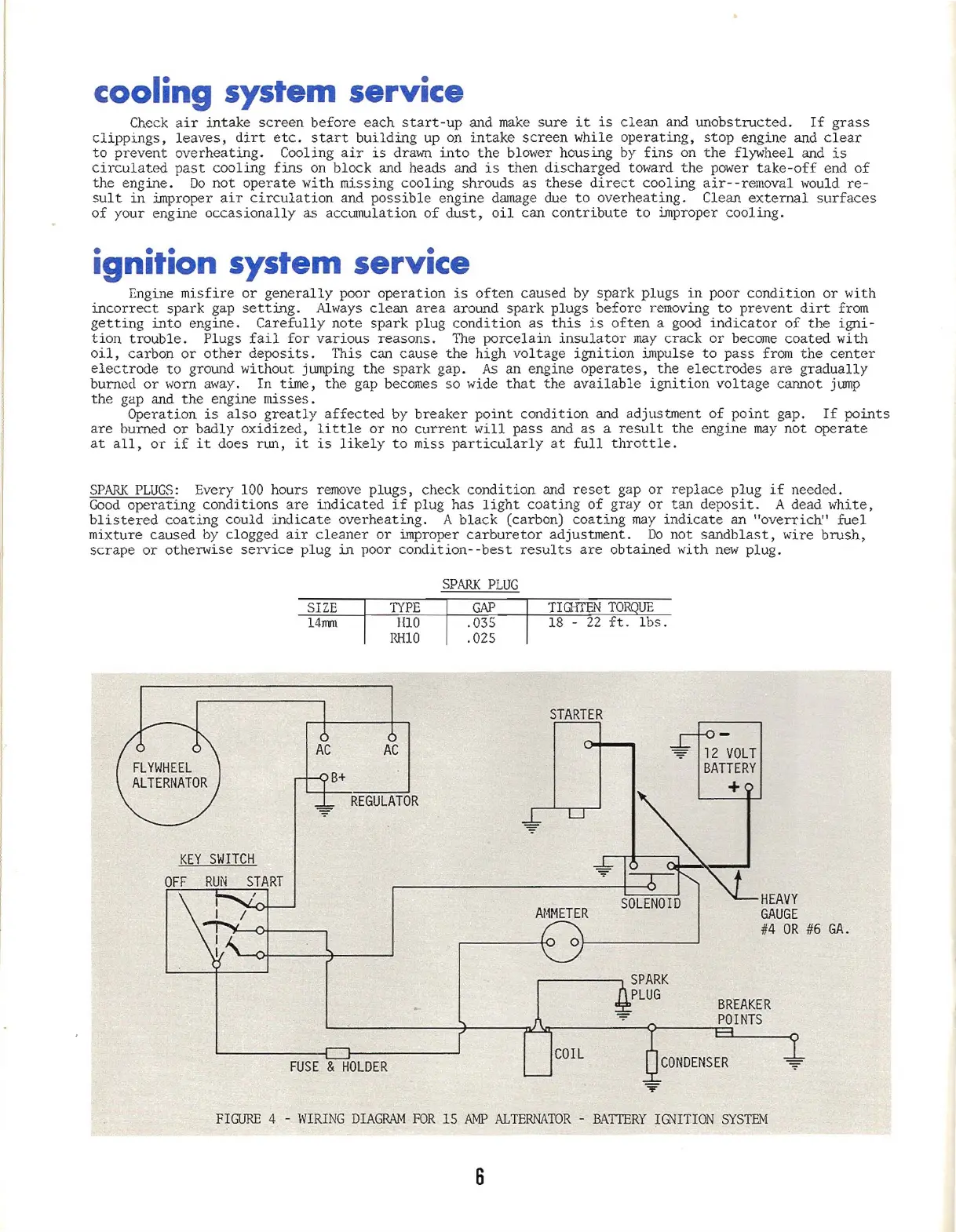

SPARK

PLUG

SIZE

14mm

TYPE

III0

nno

GAP

.035

.025

TI

GI-ITEN

TO

UE

18 - 22

ft.

lbs.

HEAVY

GAUGE

#4

OR

#6

GA.

BREAKER

POINTS

12

VOLT

BATTERY

+

CONDENSER

COIL

STARTER

Of---------'

Ar-IMETER

,....-----,

SPARK

PLUG

AC

REGULATOR

FUSE

&

HOLDER

FI

GURE

4 - WIR

ING

DIA

GRAM

FOR

15

AMP

ALTERNATOR

-

BATIERY

IGNITI

ON

S

YS

TEM

6

Loading...

Loading...