99

Z

Z1

Z2

B

C

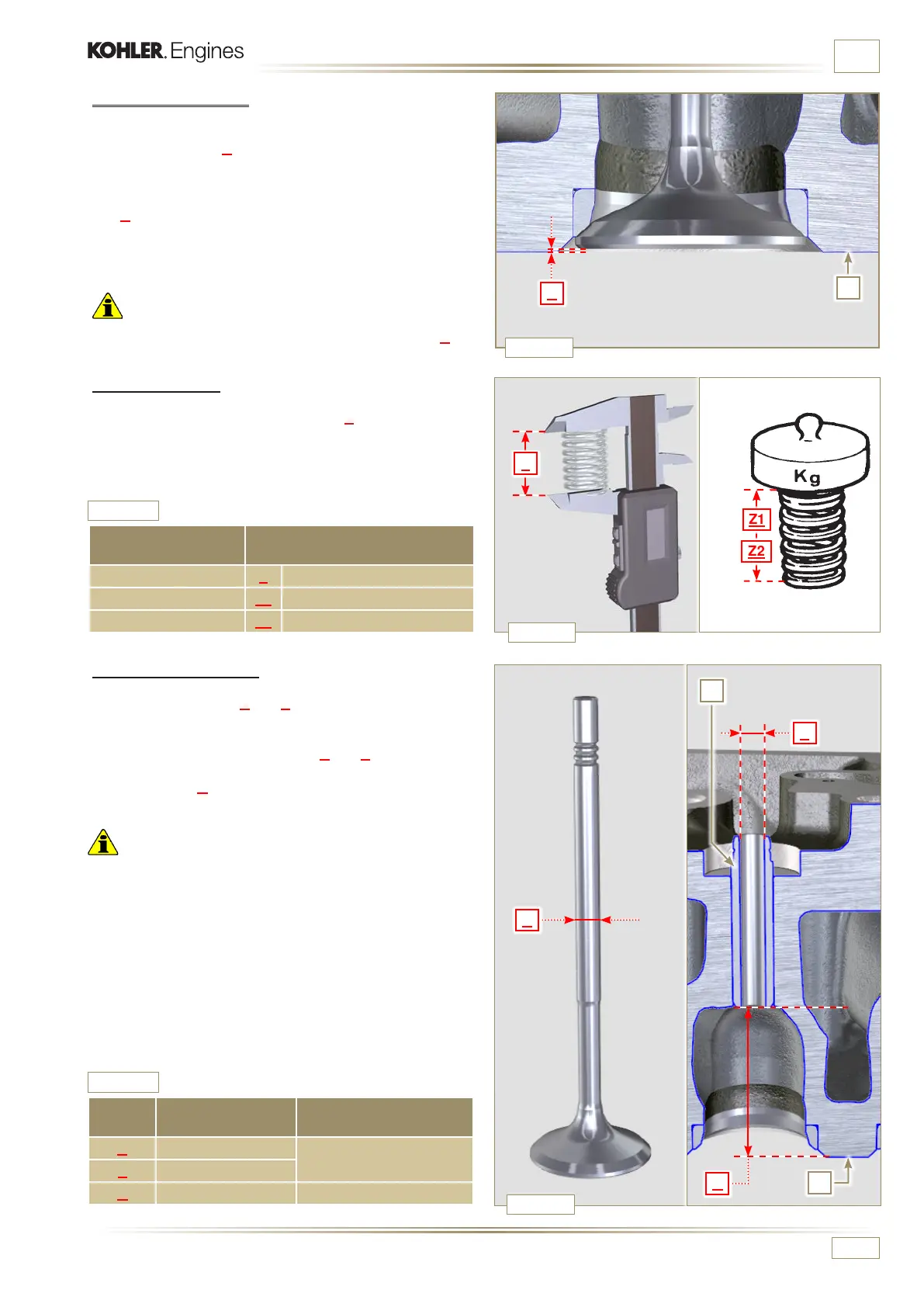

Fig. 8.21

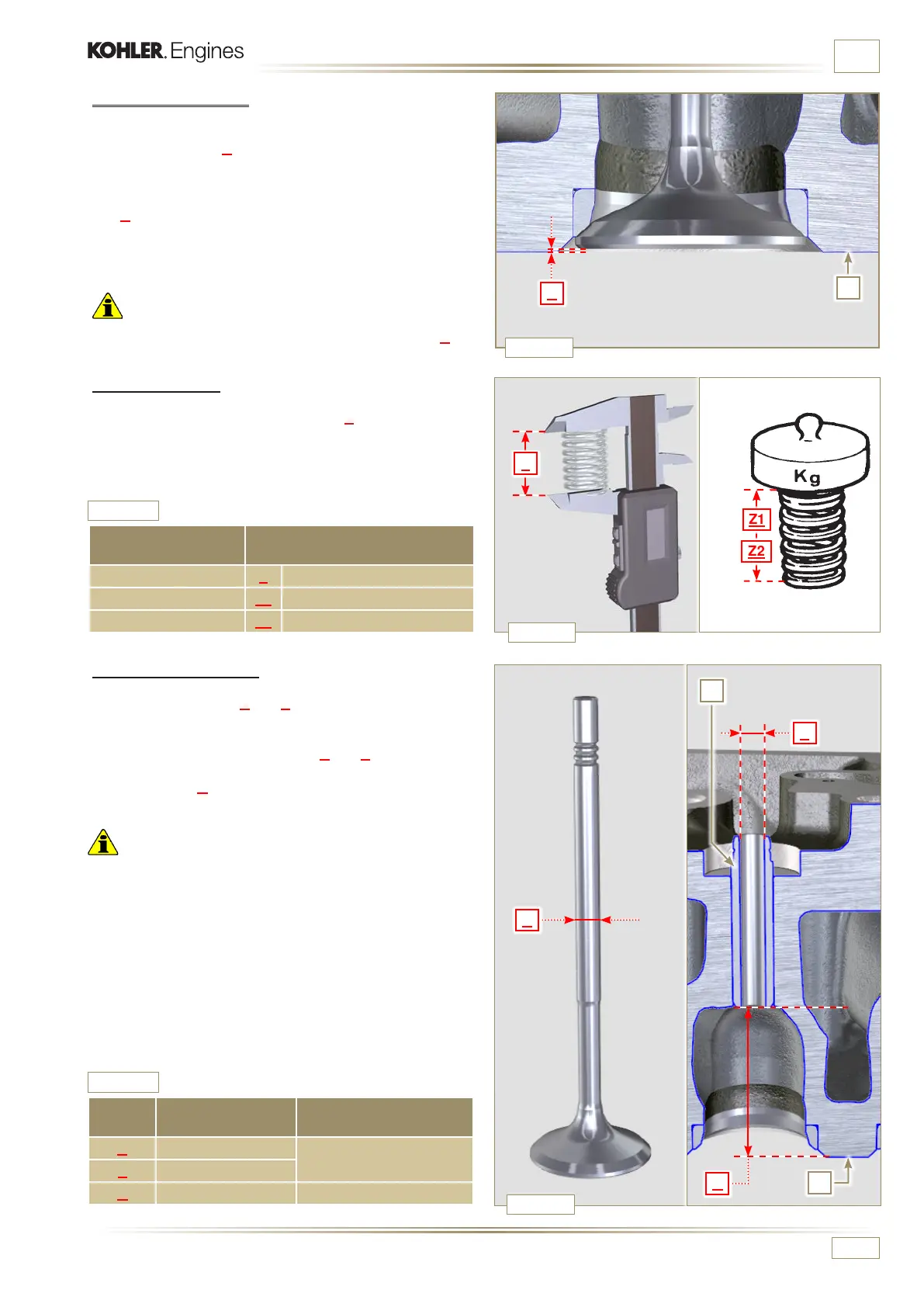

Fig. 8.22

D

E

G

F

H

Fig. 8.20

Tab. 8.10

Tab. 8.11

ED0053030410

INFORMATION ABOUT OVERHAULING

8.6.2 Valve seats check

Thoroughly clean the valves and their seats with.

Measure indentation B o f e a c h v a l v e w i t h r e g a r d t o t h e c y l i n d e r

head surface C, which is to be a MIN of 0.50 mm and MAX

of 0.53 mm.

The B MAX indentation allowed on worn components is 0.90

mm.

If the measured value does not correspond with the values

indicated, replace the worn component.

Important

• The seats must be worked after driving to reach value B, go

to a rectification workshop for such operations.

8.6.3 Valve springs

Use a gauge to measure the free length Z.

Using a dynamometer, subject the spring to two different

forces and check that the length of the spring corresponds to

the values indicated in the Tab. 8.10.

WEIGHT (kg) LENGTH (mm)

0

Z 42.50

20,4

Z1 33.00

42,8

Z2 23.80

8.6.4 Valve guides check

Measure the diameters D and E of the rods and guides valve

(Tab. 8.11).

The MAX allowed value of wear for D and E is 0.10 mm.

Observe values G from surface F when assembling guides

H (Tab. 8.11).

Important

• Carry out the measurements in different points to detect any

ovalisation and/or concentrated wear.

• Tab. 8.11 details the dimensional values of new components

only.

REF. DIMENSIONS (mm)

CLEARANCE VALUE (mm)

D 5.978 - 5.990

0.040 - 0.064

E 6.030 - 6.042

G 38.300 - 38.700

Valve stem - valve guide dimensions

Loading...

Loading...