27

2

_07ED0053029590

TECHNICAL INFORMATION

2.9.1 Injection circuit (pressure 2000 bar) (Fig. 2.4)

The materials of the fuel system components (pipes, tank,

lters, etc.) and any surface treatments must be free from

chemical elements that, transported in the fuel, compromise

the operation of the injectors over time (hole clogging).

Important

• The high pressure injection system is highly susceptible to

damage if the fuel is contaminated.

• It is crucial that all components of the injection circuit are

thoroughly cleaned before the components are removed.

• Thoroughly wash and clean the engine before maintenance.

• Contamination in the injection system may cause a reduction

in in performance or engine faults.

• If the engine is cleaned with high pressure washer, then the

nozzle must be kept at a minimum distance of 200mm from

the surface, and not directed at electrical components and

connectors.

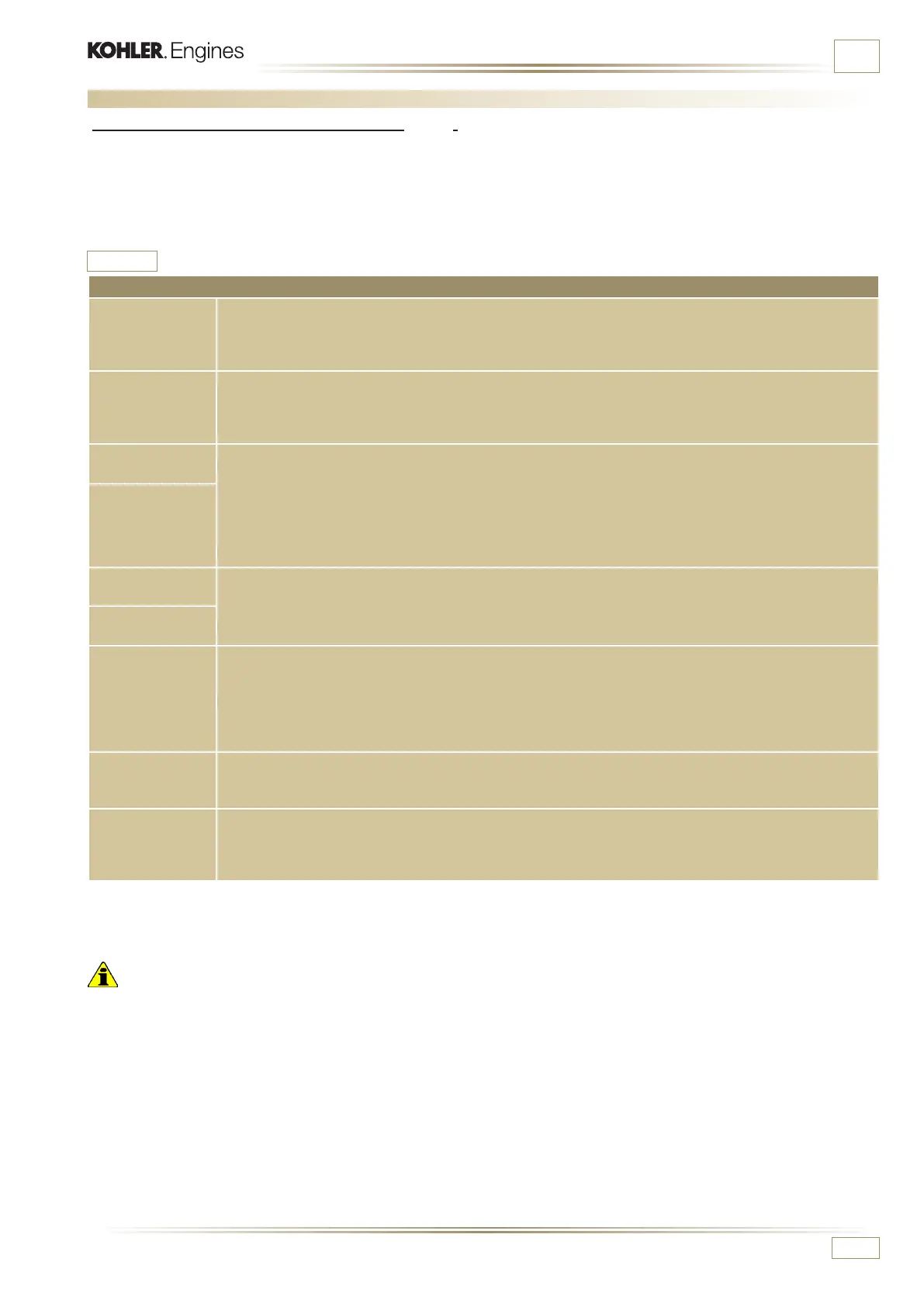

POLLUTANTS LIMIT VALUES OF PRESENCE IN FUEL

Zn

(Zinc)

. Zinc (Zn) is contained in the rubber of the supply hoses. The increase of Zinc Oxide (Zn) adheres to the

components of the injection system.

. In the event of a clogged electroinjector, it may be the high content of Zinc (Zn) causing the problem.

. The maximum allowed limit of zinco (Zn) is ≤ 3ppm

Pb

(Lead)

. Lead (Pb) is contained in the paints that coat the tanks.The increase of lead (Pb) in the fuel is deposited

on the injection components, compromising their operation.

. In the event of a clogged electro injector, it may be the high content of Lead (Pb) causing the problem.

. The maximum allowed limit of lead (Pb) is ≤ 3ppm

Na

(Sodium)

. The increase of Sodium (Na) in the fuel, adhering to the injection components in quantities ≥ 0.5 ppm

can cause electronic injector malfunctions.

. In the event of a clogged electronic injector, it may be the high content of Sodium (Na) causing the

problem.

. In this specic problem, NaOH are the residues that can be found, for example, in biofuels, Na ≥ 0.3

ppm is the limit value to prevent the problem. The combination of the two components K and Na must be

less than 0.3 ppm.

K

(Potassium)

Ca

(Calcium)

. Calcium (Ca) causes problems by adhering to the injection components.

. It is currently under study.

. Ad interim, a maximum value of 0.5 ppm is allowed when using a fuel with specication: B100 and

EN 14214 with a 10% content.

Mg

(Magnesium)

Cu

(Copper)

. Copper (Cu) in the fuel can cause irregular wear to the injection systems or clog the holes of the injec-

tors.

. In the event of a clogged injector electronic injector, it may be the high content of Copper (Cu) causing

the problem.

. Ad interim, the maximum allowed value is the same as Zn. The maximum allowed limit of Copper (Cu) is

≤ 3ppm.

Ba

(Barium)

. High contents of Barium (Ba) in the fuel can cause malfunctions in the injection systems.

. Ad interim, the maximum allowed value is the same as Zn. The maximum allowed limit of Barium (Ba) is

≤ 3ppm.

P

(Phosphorus)

. Phosphorus (P) in the fuel can cause premature wear of the catalyst.

. There are currently no contraindications for injection systems.

. Ad interim, the maximum allowed value is 1ppm when using a B100 fuel with EN 14214 specications,

with a 10% content.

Tab. 2.10

2.9 Fuel system

The most critical chemical element is Zinc (Zn), therefore it is

forbidden to use galvanised components.

Other damaging elements are indicated in the table below.

Loading...

Loading...