6

77

_07

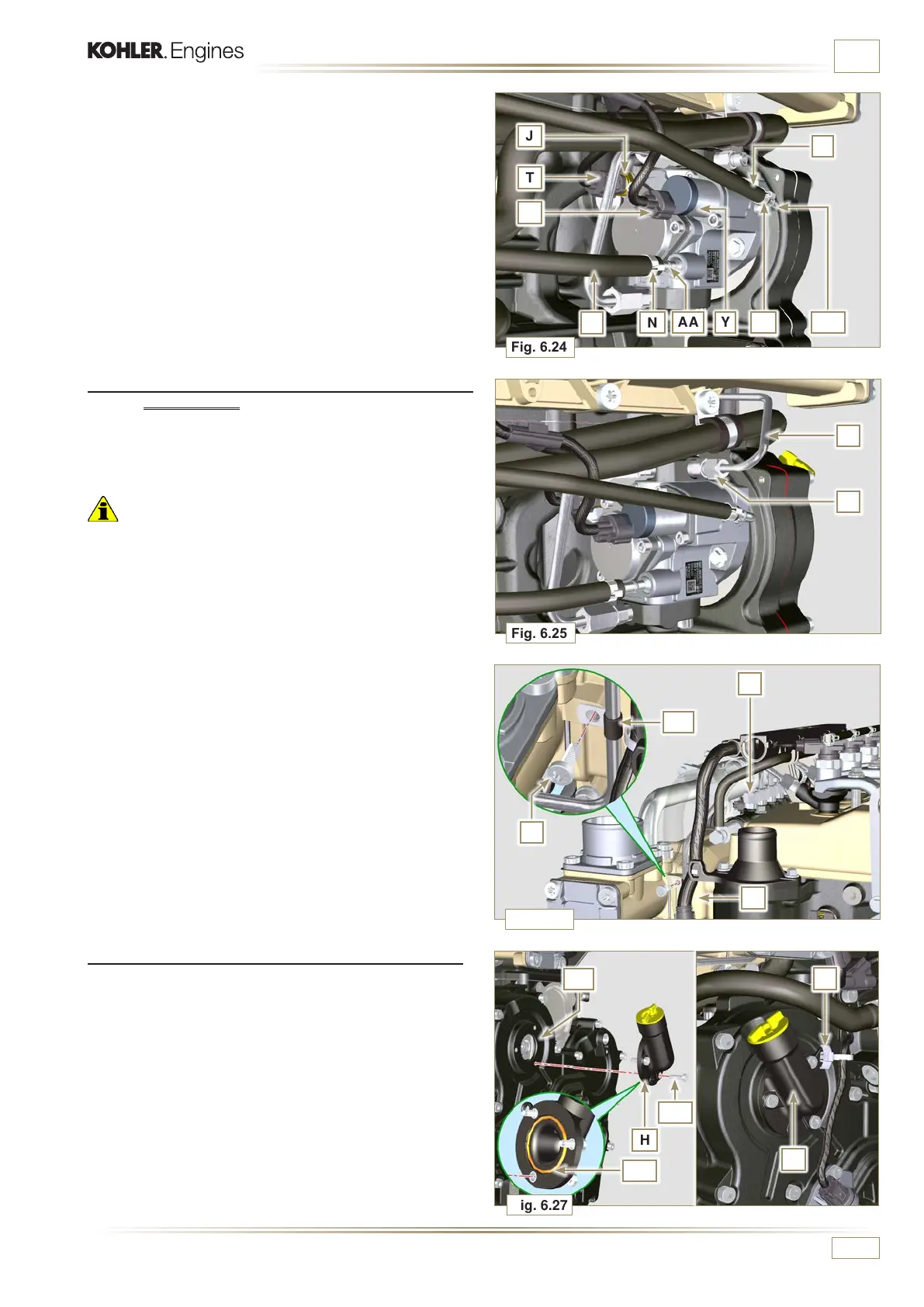

Fig. 6.24

Q

N

AA Y

N

AB

P

Fig. 6.25

F

J

T

S

A

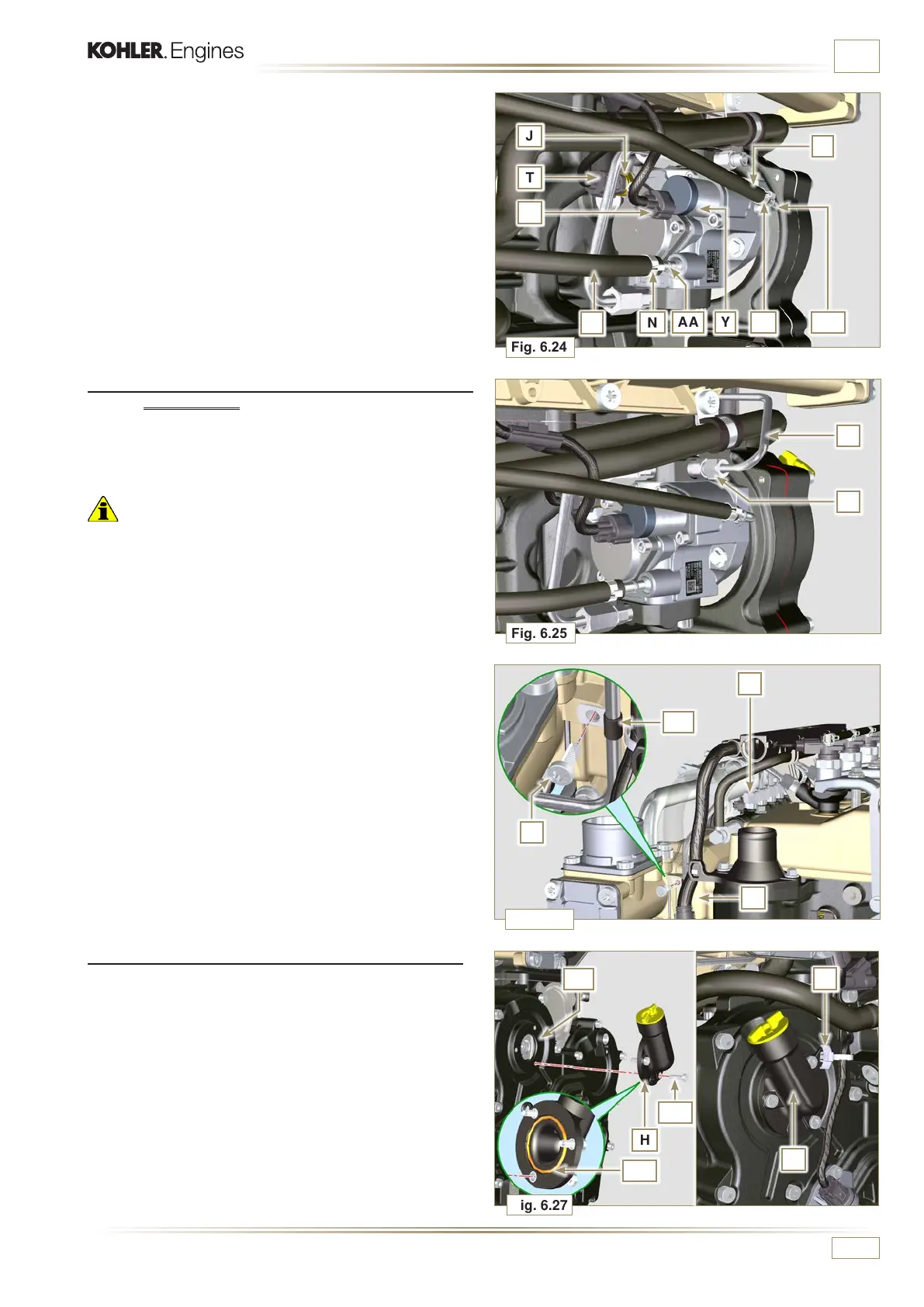

Fig. 6.27

H

AF

AG

AE

E

Fig. 6.26

AC

D

C

B

H

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

6.2.5 High-pressure line assembly (injection pump /

Common Rail)

1 - Remove the protection cap.

2 - Position the pipe F.

Important

• Manually tighten the nut A.

7 -

Fit the connector T on the sensor J.

8 -

Fit the connector S on the sensor Y.

9 - Remove the protection caps.

10 - Fit the pipe Q on the fitting AA.

11 - Fit the pipe P on the fitting AB.

12 - Hook the clamps N on the hoses Q and P.

3 -

Manually tighten the nut D.

4 - Fix clamp AC by means of capscrew B on intake manifold

C (tightening torque 10 Nm - ST_06).

5 - Clamp nut D (tightening torque at 30 Nm) and A (tightening

torque at 25 Nm) in sequence.

6.2.6 Timing system carter oil lling ange assembly

NOTE: Always replace the gasket AE after each assembly.

1 - Position the gasket AE in the set on the flange H.

2 - Fix the flange H on the crankcase AF with the screws AG

(tightening torque at 10 Nm - ST_06).

3 - Fit the clamp E on the flange H.

4

- Disassemble the special tool ST_34 and assemble the starter

motor (tightening torque 45 Nm).

Loading...

Loading...