SECTION 6

ELECTRICAL SYSTEMS AND

COMPONENTS

Problem

BATTERY

NOT

CHARGING

BATTERY

CONTINUOUSLY

CHARGING

AT

HIGH RATE

NOTES:

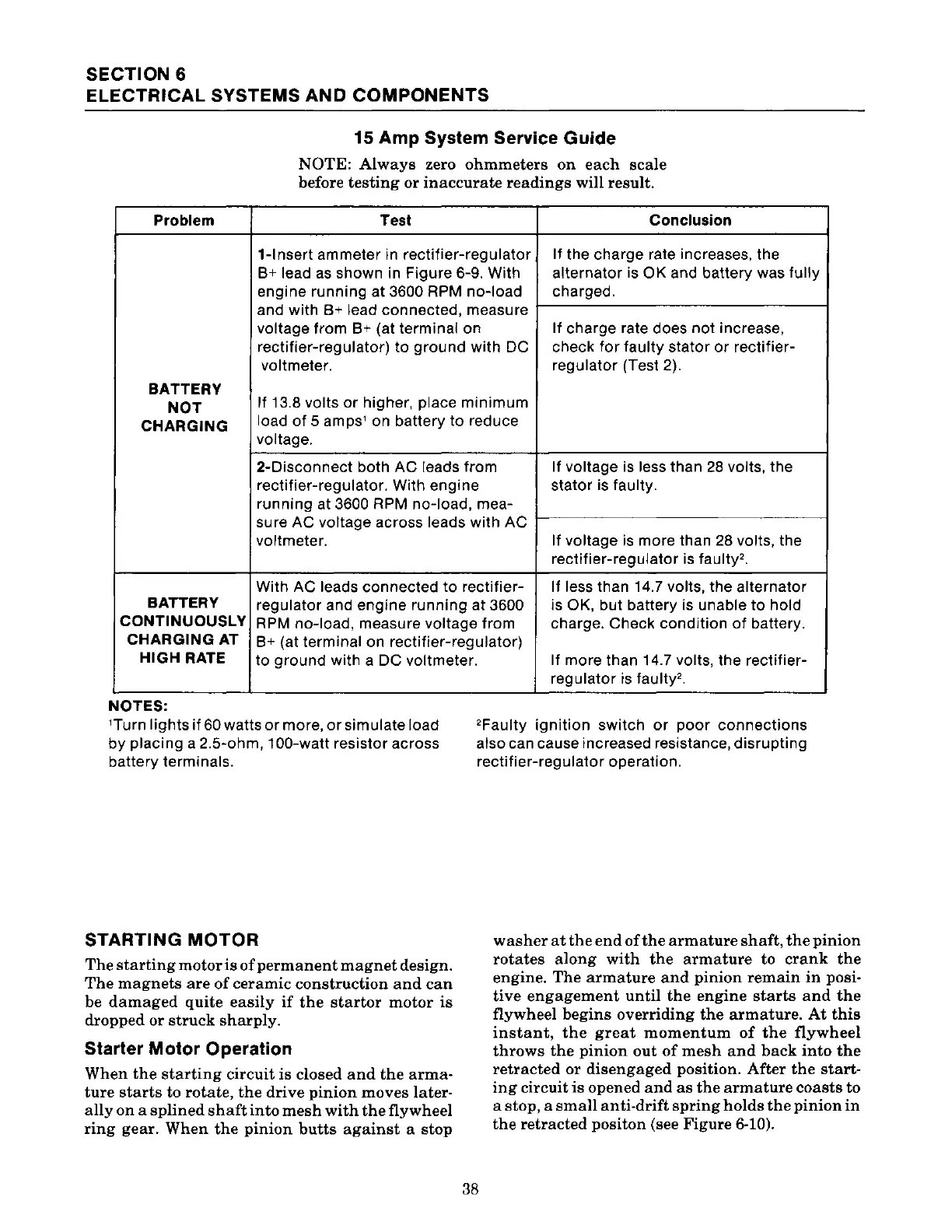

15 Amp System Service Guide

NOTE:

Always

zero

ohmmeters

on

each

scale

before

testing

or

inaccurate

readings

will result.

Test Conclusion

1-lnsert ammeter in rectifier-regulator

If the charge rate increases. the

B+

lead

as

shown in Figure 6-9. With

alternator is

OK and battery was

fully

engine running at 3600 RPM no-load charged.

and with B+ lead connected, measure

voltage from

B+

(at terminal on

If

charge rate does not increase,

rectifier-regulator) to

ground

with DC check

for

faulty stator

or

rectifier-

voltmeter.

regulator (Test 2).

If 13.8 volts

or

higher, place

minimum

load

of

5 amps' on battery

to

reduce

voltage.

2-Disconnect both

AC

leads from

If

voltage is less than

28

volts, the

rectifier-regulator. With engine stator is faulty.

running at 3600 RPM no-load, mea-

sure AC voltage across leads with AC

voltmeter.

If voltage

is

more than

28

volts, the

rectifier-regulator is faulty'.

With

AC leads connected

to

rectifier- If less than 14.7 volts, the alternator

regulator and engine running at 3600 is

OK, but battery is unable

to

hold

RPM

no-load, measure voltage from charge. Check condition

of

battery.

B+

(at terminal on rectifier-regulator)

to

ground

with a DC voltmeter.

If

more than 14.7 volts, the rectifier-

regulator

is

faulty'.

'Turn lights

if

60 watts

or

more,

or

simulate load

by

placing a 2.5-ohm, 100-watt resistor across

battery terminals.

'Faulty

ignition

switch

or

poor

connections

also can cause increased resistance, disrupting

rectifier-regulator operation.

STARTING

MOTOR

The

starting

motor

is

of

permanent

magnet

design.

The

magnets

are

of

ceramic

construction

and

can

be

damaged

quite

easily

if

the

startor

motor

is

dropped

or

struck

sharply.

Starter Motor Operation

When

the

starting

circuit

is

closed

and

the

arma-

ture

starts

to

rotate,

the

drive

pinion

moves

later-

ally

on

a

splined

shaft

into

mesh

with

the

flywheel

ring

gear.

When

the

pinion

butts

against

a

stop

38

washer

at

the

end

of

the

armature

shaft,

the

pinion

rotates

along

with

the

armature

to

crank

the

engine.

The

armature

and

pinion

remain

in

posi-

tive

engagement

until

the

engine

starts

and

the

flywheel

begins

overriding

the

armature.

At

this

instant,

the

great

momentum

of

the

flywheel

throws

the

pinion

out

of

mesh

and

back

into

the

retracted

or

disengaged

position.

After

the

start-

ing

circuit

is

opened

and

as

the

armature

coasts

to

a

stop,

a

small

anti-drift

spring

holds

the

pinion

in

the

retracted

positon

(see

Figure

6-10).

Loading...

Loading...