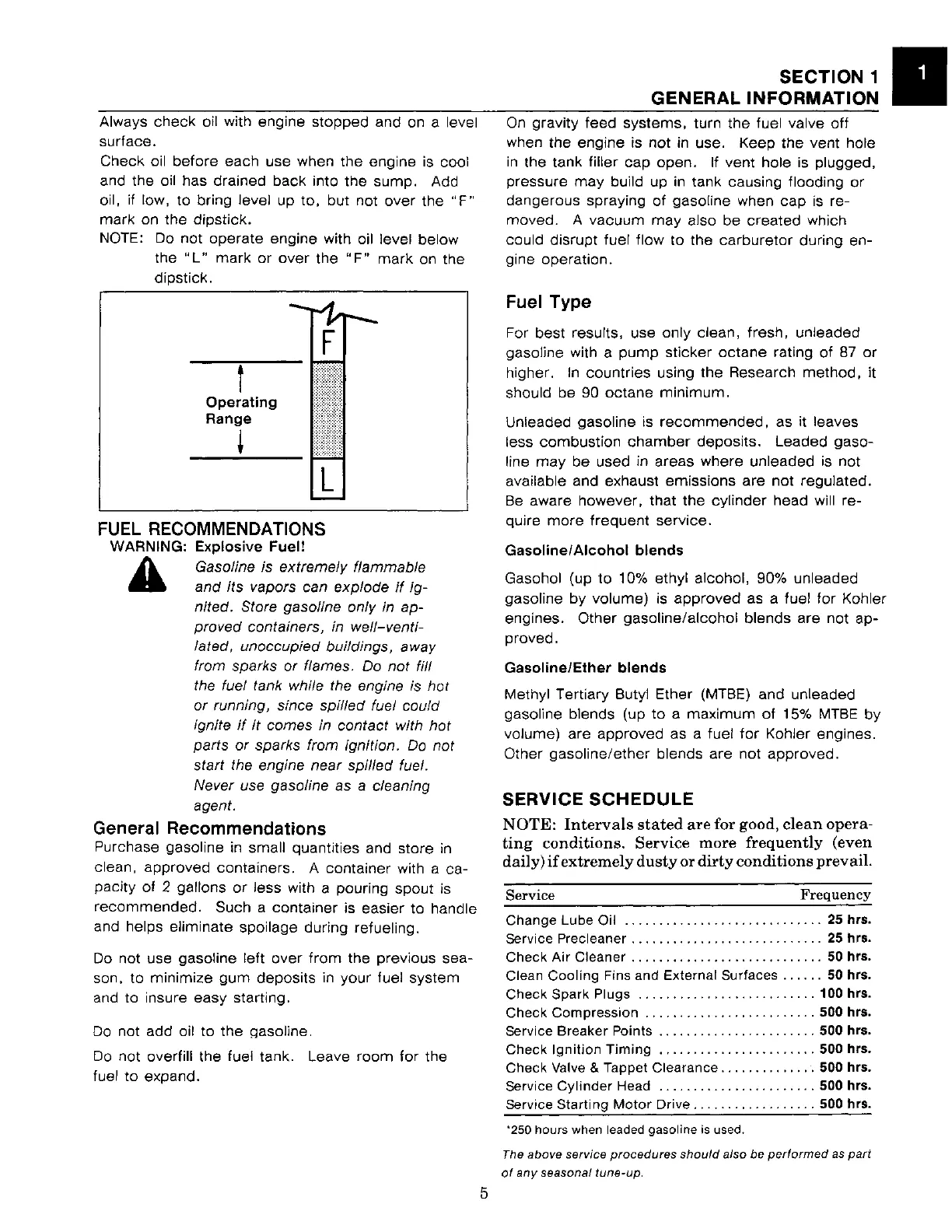

Always

check

oil with

engine

stopped

and

on a level

surface.

Check

oil

before

each

use

when

the

engine

is cool

and the oil

has

drained

back

into

the

sump.

Add

oil, if low,

to

bring

level up

to,

but

not

over

the

"F"

mark

on

the

dipstick.

NOTE: Do

not

operate

engine

with oil level

below

the

"L"

mark

or

over

the

"F"

mark

on the

dipstick.

t

Operating

Range

~

FUEL RECOMMENDATIONS

WARNING:

Explosive

Fuel!

A Gasoline is extremely flammable

..

and

its vapors can explode

if

ig-

nited.

Store gasoline only in ap-

proved

containers, in

well-venti-

lated,

unoccupied

buildings, away

from sparks

or

flames. Do

not

fill

the fuel tank while the engine is

hot

or

running, since

spilled

fuel could

ignite

if

it

comes in contact with

hot

parts

or

sparks from ignition.

Do

not

start the engine

near

spilled fuel.

Never use gasoline as a cleaning

agent.

General Recommendations

Purchase

gasoline

in

small

quantities

and

store

in

clean,

approved

containers.

A

container

with a

ca-

pacity

of

2

gallons

or

less with a pouring

spout

is

recommended.

Such

a

container

is

easier

to

handle

and helps

eliminate

spoilage

during

refueling.

Do not

use

gasoline

left

over

from

the

previous

sea-

son,

to

minimize

gum

deposits

in

your

fuel

system

and

to

insure

easy

starting.

Do not

add

oil

to

the

Qasoline.

Do

not

overfill the fuel

tank.

Leave

room

for

the

fuel

to

expand.

5

SECTION

1

GENERAL

INFORMATION

On

gravity

feed

systems,

turn

the

fuel valve

off

when

the

engine

is

not

in

use.

Keep

the

vent

hole

in

the

tank

filler

cap

open.

If

vent

hole

is

plugged,

pressure

may

build up in

tank

causing flooding

or

dangerous

spraying

of

gasoline

when

cap

is

re-

moved.

A

vacuum

may

also

be

created

which

could

disrupt

fuel

flow

to

the

carburetor

during

en-

gine

operation.

Fuel Type

For

best

results,

use

only

clean,

fresh,

unleaded

gasoline with a

pump

sticker

octane

rating

of

87

or

higher.

In

countries

using

the

Research

method,

it

should be

90

octane

minimum.

Unleaded

gasoline

is

recommended,

as it

leaves

less

combustion

chamber

deposits.

Leaded

gaso-

line

may

be

used

in

areas

where

unleaded

is

not

available

and

exhaust

emissions

are

not

regulated.

Be

aware

however,

that

the

cylinder

head

will

re-

quire

more

frequent

service.

Gasoline/Alcohol

blends

Gasohol (up

to

10% ethyl

alcohol,

90%

unleaded

gasoline

by

volume)

is

approved

as a fuel

for

Kohler

engines.

Other

gasoline/alcohol

blends

are

not

ap-

proved.

Gasoline/Ether

blends

Methyl

Tertiary

Butyl

Ether

(MTBE)

and

unleaded

gasoline blends

(up

to

a

maximum

of

15% MTBE

by

volume)

are

approved

as a fuel

tor

Kohler

engines.

Other

gasoline/ether

blends

are

not

approved.

SERVICE

SCHEDULE

NOTE:

Intervals

stated

are

for good,

clean

opera-

ting

conditions.

Service

more

frequently

(even

daily)

if

extremely

dusty

or

dirty

conditions

prevail.

Service

Frequency

Change Lube Oil

.............................

25

hrs.

Service Precleaner

............................

25 hrs.

Check Air Cleaner

............................

50

hrs.

Clean

Cooling

Fins

and

External

Surfaces

......

50 hrs.

Check Spark Plugs

..........................

100 hrs.

Check Compression

.........................

500

hrs.

Service

Breaker

Points

.......................

500 hrs.

Check Ignition Timing

.......................

500

hrs.

Check

Valve

& Tappet Clearance

..............

500

hrs.

Service Cylinder Head

.......................

500

hrs.

Service

Starting

Motor

Drive

..................

500 hrs.

'250

hours

when leaded gasoline is used.

The above service

procedures

should

also be

performed

as

part

of

any seasonal tune-up.

Loading...

Loading...