GASOLINE FUEL PUMP

The fuel pump does not require regular service but may have to be rebuilt to restore normal

efficiency after extended hours of operation.

If your engine falters or stumbles each time the load is

increased, this may be due to a worn-out fuel pump.

The repair kit listed in the parts manual for this

pump includes all parts necessary to restore normal efficiency of the fuel pump. Remove fuel pump

from engine and rebuild as follows:

DISASSEMBLY

_

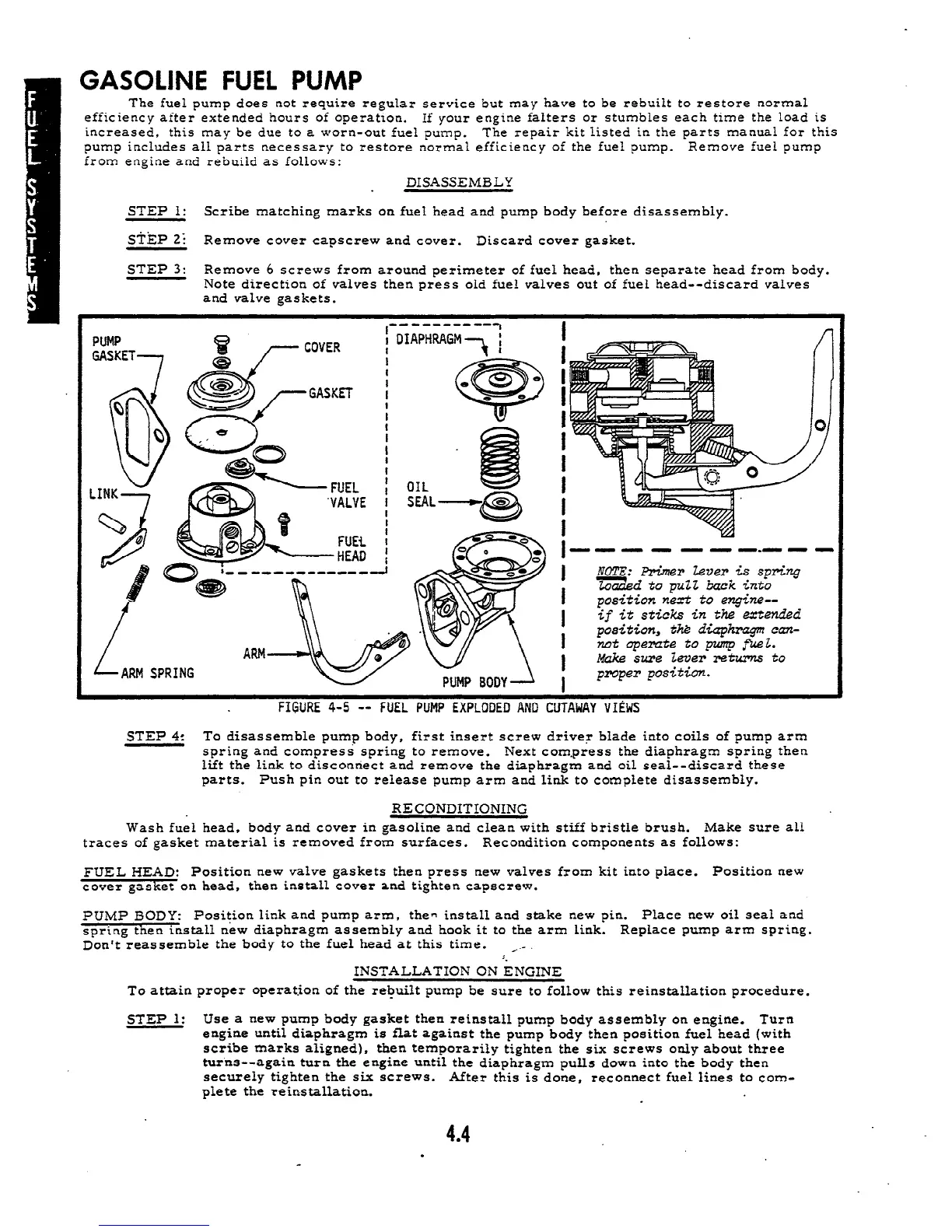

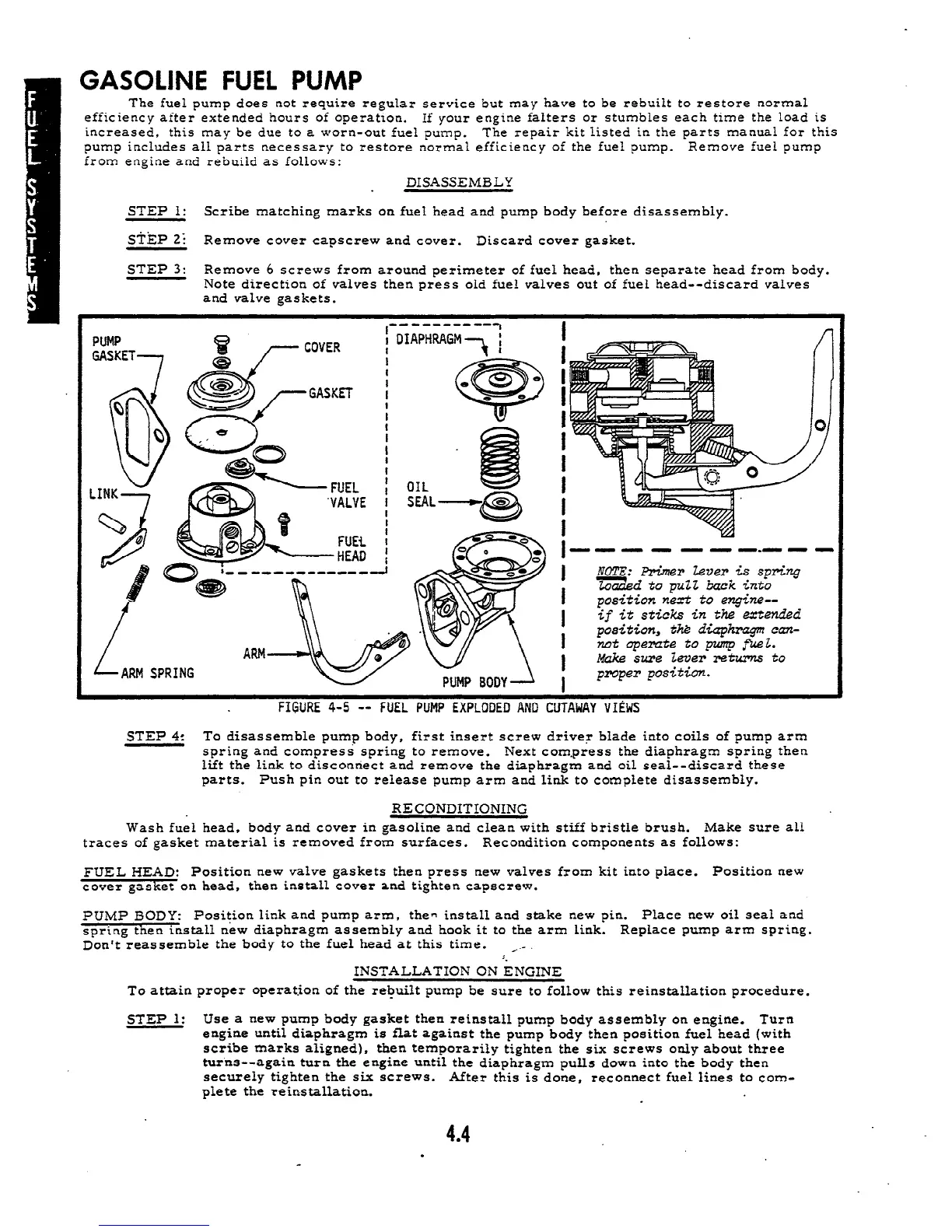

STEP 1: Scribe matching marks .on fuel head and pump body before disassembly.

STEP 2:

Remove cover capscrew and cover. Discard cover gasket.

STEP 3: Remove 6 screws from around perimeter of fuel head,

then separate head from body.

Note direction of valves then press old fuel valves out of fuel head--discard valves

and valve gaskets.

GASKET-/

m

es

PUMP

53

COVER

: DIAPHRAGM

I

-f

!

3

a

I

m

'VALVE i

SEAL-

x

L-ARM SPRING

v?

PUMP BODYa

n

NOTE: Primer lever is spring

‘r&d to DUZZ back into

position At to engine-

if it sticks in the atended

position, t?& diaphmgm cm-

not operate to pump fbeZ.

Make su2-w teverretums to

proper posCtion.

.

FIGURE 4-5

-- FUEL PUMP EXPLODED AND

CUTAWAY VIEWS

STEP 4: To disassemble pump body, first insert screw driver blade into coils of pump arm

spring and compress spring to remove.

Next com.press the diaphragm spring then

lift the link to disconriect and remove the diaphragm and oil seal--discard these

parts. Push pin out to release pump arm and link to complete disassembly.

RECONDITIONING

Wash fuel head, body and cover in gasoline and clean with stiff bristle brush.

Make sure all

traces of gasket material is removed from surfaces.

Recondition components as follows:

FUEL HEAD: Position new valve gaskets then press new valves from kit into place. Position new

cover gasket on head,

then install cover and tighten capscrew.

PUMP BODY: Position link and pump arm,

the- install and stake new pin. Place new oil seal and

spring then install n&w diaphragm assembly and hook it to the arm link.

Replace pump arm spring.

Don’t reassemble the body to the fuel head at this time.

/.- *

INSTALLATION ON ENGINE

To attain proper operation of the rebuilt pump be sure to follow this reinstallation procedure.

.

STEP 1:

Use a new pump body gasket then reinstall pump body assembly on engine. Turn

engine until diaphragm is flat against the pump body then position fuel head (with

scribe marks aligned), then temporarily tighten the six screws only about three

turns--again turn the engine until the diaphragm pulls down into the body then

securely tighten the six screws.

After this is done,

reconnect fuel lines to com-

plete the reinstallation.

.

44

0

Loading...

Loading...