4 5

OPERATOR’S COMPARTMENT

D85ESS

CRAWLER DOZER

D85ESS-2A C RAWLER D OZER

Electronic monitoring

system (optional)

An electronic monitoring

system prevents minor

problems from developing

into major ones. All meters

and gauges are controlled by

a microcomputer, which

provides a wide indication

range for an easier, more precise reading.

Hexagonal pressurized cab (optional)

Air filters and a higher internal air pressure combine to

prevent external dust from entering the cab. In addition, the

cab’s hexagonal design provides excellent front, side, and

rear visibility. The viscous damper cab suspension softens

shocks for operator comfort and extends component life.

Low-noise design

For smoother riding comfort, power train components and

hydraulic control valves are mounted to the frame with

rubber pads to soften vibration and shut out noise.

Since the D85ESS employs joysticks, the walk-through

operator compartment is uncluttered for smooth entry

and exit. An adjustable seat with backrest is standard

equipment.

Three-stage height adjustable armrests

Three-stage height adjustable armrests and relocated fuel

control lever provide

comfortable operation and

increased leg space.

Easy-to-operate work equipment control lever

With the Closed-center Load Sensing (CLSS) hydraulic

system, blade lever stroke is directly proportional with blade

speed, regardless of the load and travel speed. This results

in superb, fine controllability.

Benefits of CLSS

● More precise and responsive operation due to the

pressure compensation valve.

● Reduced fuel consumption by discharging only the

required amount of oil from the pump.

● The work equipment moves smoothly for operations such

as side-cutting even when priority is given to steering.

All steering, direction, and speed changes are made by a left-hand single joystick control. If the operator wants to

move the machine forward and to the left, he simply moves the joystick forward and to the left. If he desires a gear change,

he merely twists his wrist. The machine responds to the movement of the lever providing the operator with the feeling of

natural control with Komatsu’s joystick.

CLSS for D85ESS-2A

Steering

functions

Forward and

reverse

Right and left

steering

First, to second,

to third shifting

Left Hand

Right Hand

Blade

functions

Lifting and

lowering

Tilting

RELIABILITY FEATURES

E

ASY

M

AINTENANCE

Field-proven engine

Powerful S6D125E-2 diesel engine provides a massive

output of

149 kW 200 HP. The engine power is transmitted

smoothly to the final drives via a high-efficiency torque

converter.

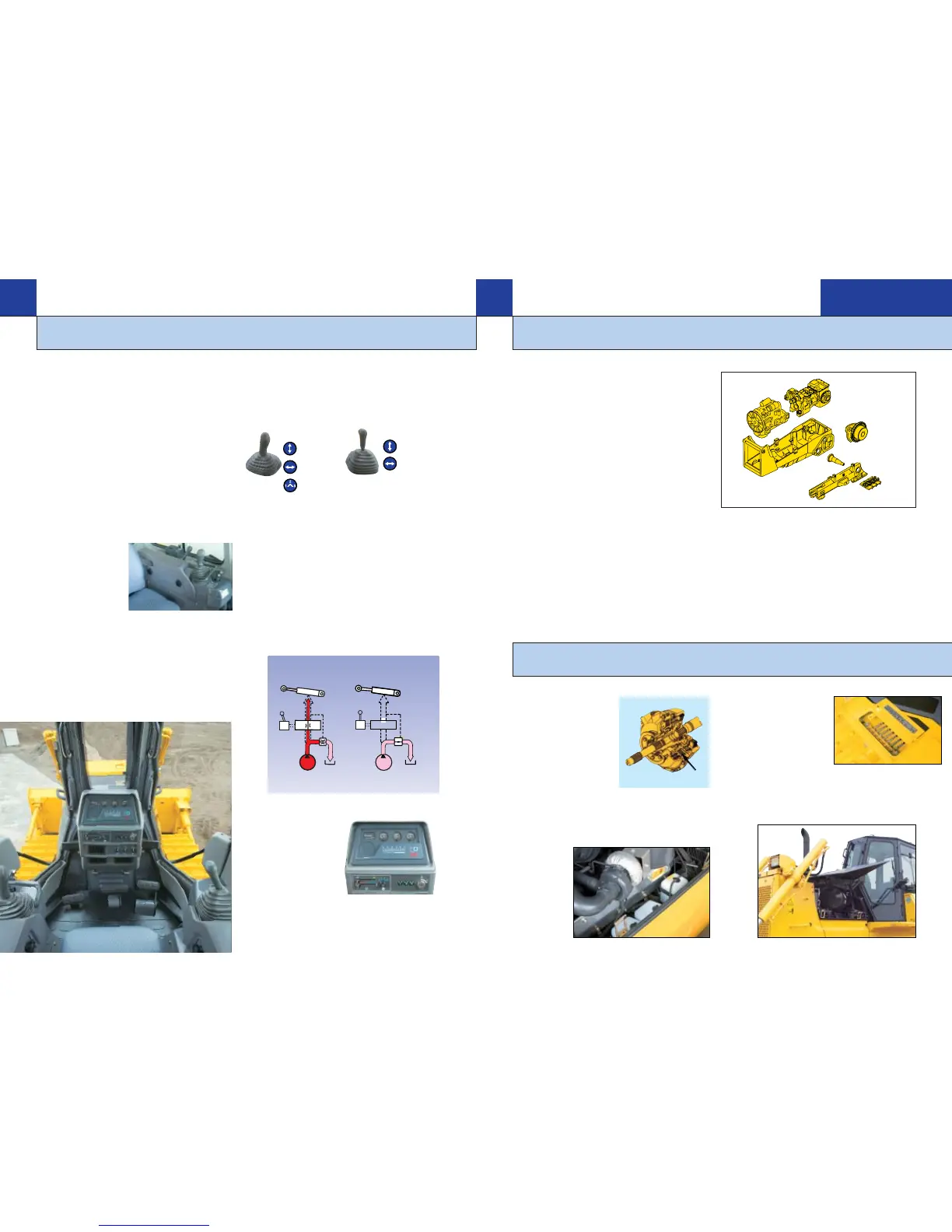

Modular designed power train units

The modular design allows easy removal and installation of

any individual unit for shorter downtime.

Flat bottom frame

A flat bottom frame, the monocoque track frames and

forward-mounted pivot shafts provide good maneuverability

in muddy terrain by preventing mud from building up under

the frame.

Sturdy design

Because fewer components mean greater reliability, we’ve

designed a simple hull frame made of a thick, single plate.

Tr ack frames have a large-section construction for maximum

rigidity. Even the box-section construction of the blade back

beam is reinforced, all with durability in mind.

Wet, multiple-disc brakes

Eliminate brake-band

adjustments for

maintenance-free operation.

Coolant reservoir

A radiator coolant reservoir makes it easier to

check the coolant level and eliminates

frequent refilling.

Oil pressure check ports

(optional)

Oil pressure check ports for the

power train are centralized on the

right hand side of the operator

platform for easy access.

Gull-wing engine side covers (optional)

A gas-spring cylinder opens the gull-wing engine side covers

widely, allowing the engine and auxiliary components to be

easily checked.

Tough undercarriage

Large-diameter bushings, increased track link heights, and

improved oil-seals help to increase undercarriage durability.

Serviceability has also been improved with the addition of

remote greasing of the equalizer bar center pin.

Low drive and long track undercarriage

Komatsu’s design is extraordinarily tough and offers excellent

grading ability and stability.

Loading...

Loading...