• The loading and unloading of the machine on/from the means of transport must be carried out on a flat

surface and at a safety distance from the edges of ditches or from the road side.

• Block the means of transport by positioning wedges before and behind each wheel.

• Make sure that the ramps are sufficiently strong; if necessary, reinforce them with blocks, in order to

prevent any dangerous bending.

• Make sure that the ramps have the same length, are firmly anchored to the motor vehicle, are parallel to

each other and perpendicular to the loading board; the distance between the ramps must be suitable

for the machine gauge.

• Position the ramps with a maximum inclination of 15°.

• Remove any trace of oil, grease or ice from the ramps and the loading board.

• Do not change direction when the machine is already on the ramps; if necessary, go down and find the

correct direction.

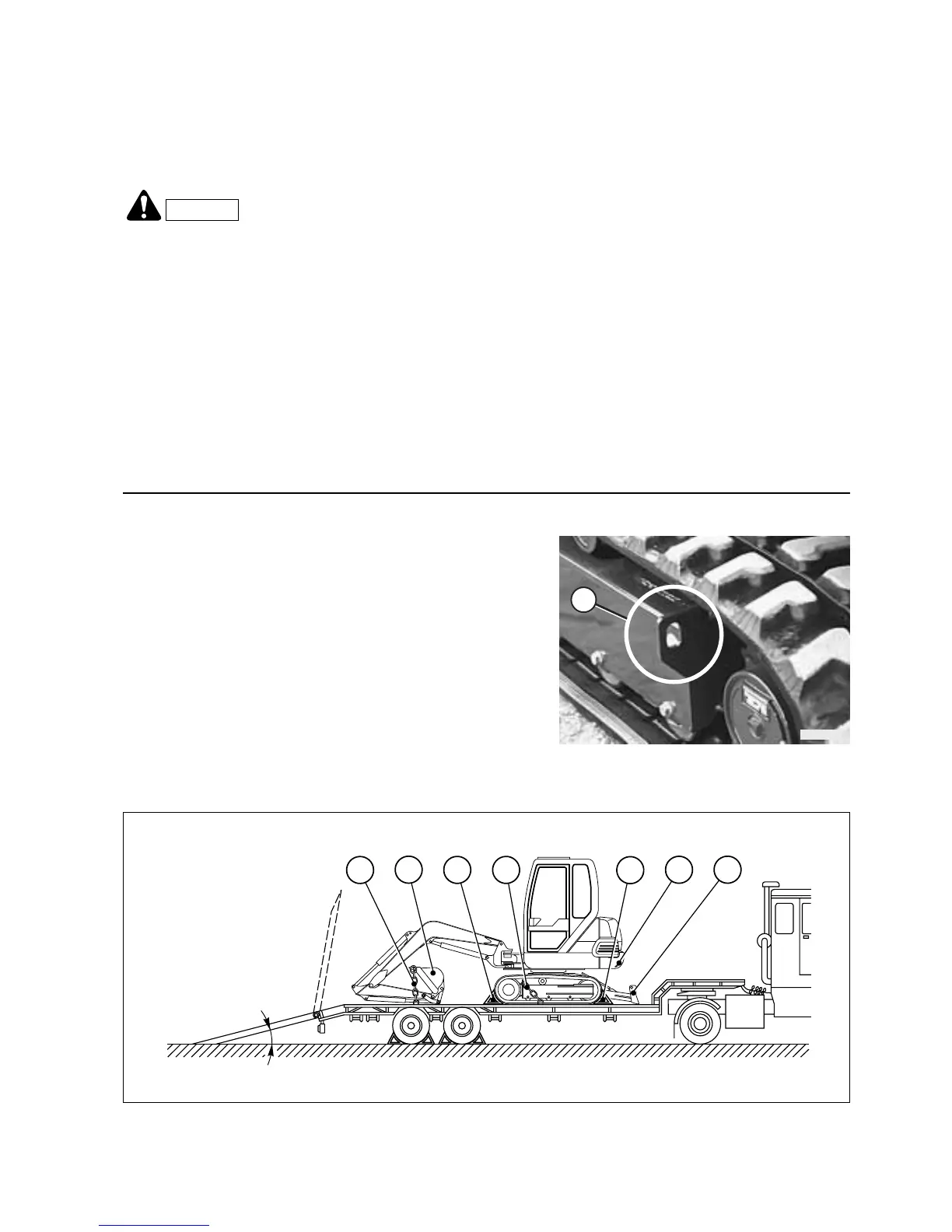

1 - The machine must get on the ramps with the bucket (1) di-

rected forward and raised from the ground.

2 - Once the machine has been loaded, rotate the upper struc-

ture by 180° and engage the antirotation lock, lower the blade

(2) and the work equipment to the ground and shift the safety

device lever to the lock position.

3 - Stop the engine and remove the ignition key.

4 - Keep the machine in position also by putting wedges (3) be-

fore and behind the tracks.

5 - Fix the machine with tie-downs or chains (4) in the anchorage

points (6).

6 - Protect the end of the exhaust pipe (5).

RWA06030

6

RWA07450

4

1

3

4

3

5

2

Max. 15°

Loading...

Loading...